A supplier quality audit checklist form ensures consistent evaluation of vendor performance and compliance with industry standards. Key elements often include documentation review, process verification, and product quality assessment. Implementing a thorough checklist helps identify areas for improvement and mitigates risks in the supply chain.

Supplier Quality Audit Checklist Form Sample PDF Viewer

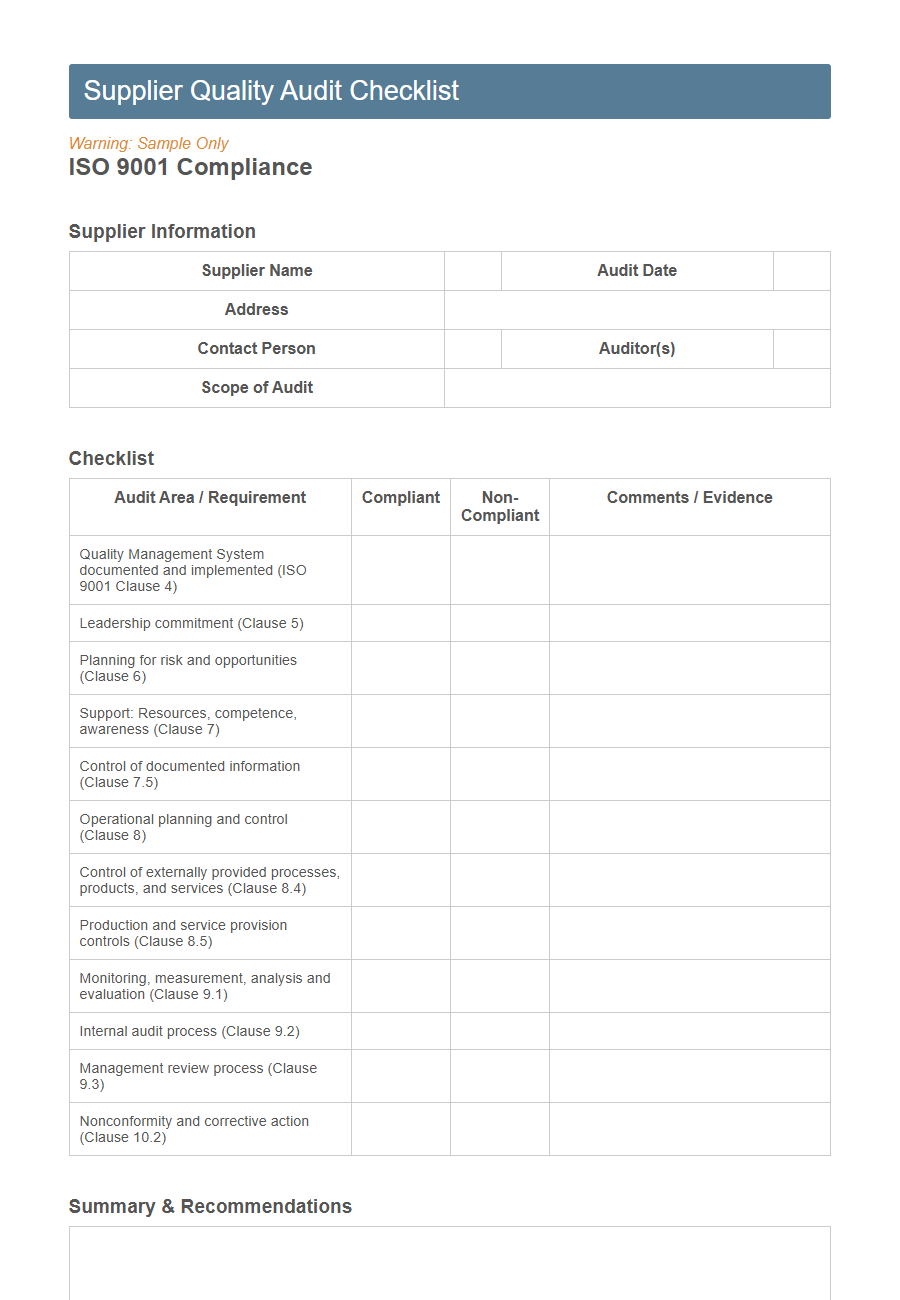

Image example of Supplier Quality Audit Checklist Form:

Supplier Quality Audit Checklist Form Samples

Supplier Quality Audit Checklist for ISO 9001 Compliance - PDF - HTML

Raw Material Supplier Quality Assessment Template - PDF - HTML

Supplier Process Capability Audit Form - PDF - HTML

Food Industry Supplier Hygiene Audit Checklist - PDF - HTML

Electronics Component Supplier Quality Audit Template - PDF - HTML

Packaging Supplier Compliance Audit Checklist - PDF - HTML

Pharmaceutical Supplier GMP Audit Checklist - PDF - HTML

Automotive Parts Supplier Quality Audit Form - PDF - HTML

Textile Supplier Sustainability Audit Template - PDF - HTML

Chemical Supplier REACH Compliance Audit Checklist - PDF - HTML

Medical Device Supplier Quality Evaluation Form - PDF - HTML

Construction Material Supplier Audit Checklist - PDF - HTML

Aerospace Supplier AS9100 Quality Audit Template - PDF - HTML

Introduction to Supplier Quality Audit Checklist Forms

What is the purpose of a Supplier Quality Audit Checklist Form? A Supplier Quality Audit Checklist Form ensures that suppliers meet defined quality standards and comply with contractual requirements. It serves as a structured tool to evaluate supplier performance consistently.

How does a Supplier Quality Audit Checklist Form benefit organizations? This form helps identify potential risks and areas for improvement in the supplier's processes. It supports quality assurance efforts by promoting transparency and accountability.

What key elements are typically included in a Supplier Quality Audit Checklist Form? The checklist usually covers areas such as documentation review, process control, product quality, and corrective actions. These elements provide a comprehensive assessment framework for supplier quality.

Importance of Supplier Quality Audits

Supplier Quality Audits are essential for ensuring that suppliers consistently meet quality standards and deliver reliable products. These audits help identify potential risks and drive continuous improvement in the supply chain.

- Ensures Compliance - Verifies that suppliers adhere to industry regulations and contractual requirements to maintain product integrity.

- Improves Product Quality - Detects process inefficiencies and quality issues early to prevent defects and reduce recalls.

- Strengthens Supplier Relationships - Promotes transparency and collaboration, fostering trust and long-term partnerships.

Key Components of a Supplier Quality Audit Checklist

A Supplier Quality Audit Checklist Form ensures thorough evaluation of a supplier's processes and compliance with quality standards. It highlights critical areas to verify and helps maintain consistent product quality and reliability.

- Supplier Information - Contains essential details about the supplier such as company name, contact information, and audit date for record-keeping and traceability.

- Quality Management System Compliance - Verifies the supplier's adherence to industry standards and certifications like ISO 9001 to ensure proper quality controls.

- Process and Production Controls - Assesses the supplier's manufacturing processes, equipment maintenance, and process capability to meet product specifications consistently.

Criteria for Evaluating Supplier Performance

Supplier Quality Audit Checklist Forms are essential tools for assessing and ensuring supplier performance meets established standards. These forms guide auditors through specific evaluation criteria to maintain product quality and consistency.

- Delivery Performance - Measures the supplier's ability to meet delivery schedules consistently and handle urgent orders effectively.

- Product Quality - Assesses compliance with quality specifications, defect rates, and corrective action responsiveness.

- Process Capability - Evaluates the supplier's manufacturing processes, including control measures and adherence to industry standards.

Implementing these criteria ensures a comprehensive evaluation of supplier performance to support continuous improvement and risk management.

Documentation and Recordkeeping Requirements

The Supplier Quality Audit Checklist Form ensures that all documentation and recordkeeping practices comply with established standards. It verifies that suppliers maintain accurate, complete, and up-to-date records related to quality control, production processes, and corrective actions. Proper documentation supports traceability, accountability, and continuous improvement in supplier quality management.

Common Nonconformities in Supplier Audits

Supplier Quality Audit Checklist Forms are essential tools used to evaluate a supplier's compliance with quality standards and requirements. These forms help identify areas where suppliers may fall short, ensuring consistent product quality and reliable supply chains.

Common nonconformities in supplier audits often include documentation errors, inadequate process controls, and failure to meet product specifications.

Best Practices for Conducting Supplier Quality Audits

Supplier Quality Audit Checklist Forms are essential tools for systematically evaluating a supplier's quality management processes.

Best practices for conducting supplier quality audits include thorough preparation, clear communication, and detailed documentation. Auditors should focus on compliance, process capability, and continuous improvement opportunities to ensure high-quality standards are met.

How to Customize Your Audit Checklist Form

To customize your Supplier Quality Audit Checklist Form, start by identifying the specific criteria and standards relevant to your industry and supplier requirements. Incorporate key performance indicators such as delivery timelines, product quality, and compliance with regulatory guidelines to ensure thorough evaluation. Tailor questions to address unique risks and operational processes, enhancing the audit's effectiveness in assessing supplier capabilities.

Post-Audit Actions and Follow-Up Process

The Supplier Quality Audit Checklist Form is essential for evaluating supplier compliance and performance.

Post-audit actions involve documenting all non-conformances and agreeing on corrective measures with the supplier. Follow-up processes ensure that these corrective actions are effectively implemented and verified through subsequent reviews.