Equipment calibration record form templates ensure accurate documentation of calibration activities for various instruments and machinery. These forms help maintain compliance with industry standards, improve traceability, and support quality control processes. Using well-structured templates simplifies the recording of calibration dates, results, and technician details, enhancing equipment reliability and performance.

Equipment Calibration Record Form Template Sample PDF Viewer

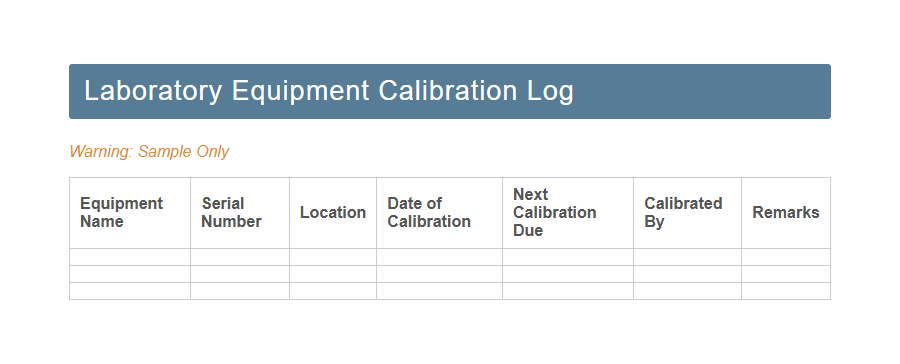

Image example of Equipment Calibration Record Form Template:

Equipment Calibration Record Form Template Samples

Laboratory Equipment Calibration Log Template - PDF - HTML

Medical Device Calibration Record Sheet - PDF - HTML

Industrial Machine Calibration Certificate Template - PDF - HTML

Weighing Scale Calibration Report Form - PDF - HTML

Thermometer Calibration Record Template - PDF - HTML

Pressure Gauge Calibration Log Sheet - PDF - HTML

pH Meter Calibration Documentation Form - PDF - HTML

Spectrophotometer Calibration Checklist Template - PDF - HTML

Pipette Calibration Record Template - PDF - HTML

Torque Wrench Calibration Report Sheet - PDF - HTML

Multimeter Calibration Certificate Template - PDF - HTML

Gas Detector Calibration Tracking Form - PDF - HTML

Autoclave Calibration Record Sheet - PDF - HTML

Introduction to Equipment Calibration Record Form Templates

Equipment Calibration Record Form Templates are essential tools for maintaining accurate and consistent calibration data. They help ensure equipment performance meets industry standards and regulatory requirements.

- Standardization - Templates provide a consistent format for recording calibration activities across various equipment types.

- Traceability - They enable tracking of calibration history to verify equipment reliability and compliance.

- Efficiency - Using templates streamlines the documentation process, reducing errors and saving time.

Implementing Equipment Calibration Record Form Templates supports quality control and operational accuracy in any technical environment.

Importance of Calibration Records in Quality Management

Why are calibration records essential in quality management? Calibration records provide documented evidence that equipment is maintained and functioning correctly. These records help ensure product accuracy, consistency, and compliance with standards.

How do calibration records impact traceability in quality control? Keeping detailed calibration records allows for tracking the history and performance of equipment over time. This traceability is crucial for audits and identifying any deviations in production processes.

What role do calibration records play in preventing equipment failure? Monitoring calibration data helps detect early signs of equipment malfunction or drift. Timely interventions based on these records reduce downtime and maintain product quality.

Key Components of an Equipment Calibration Record Form

An Equipment Calibration Record Form template is essential for maintaining accurate and reliable measurement tools.

Key components include identification details of the equipment, calibration dates, and the technician's name. It also captures calibration results, standards used, and any adjustments made during the process.

Types of Equipment Requiring Calibration Documentation

Equipment Calibration Record Form Templates are essential for maintaining accurate calibration histories across various devices. Proper documentation ensures equipment performance aligns with industry standards and regulatory requirements.

- Measuring Instruments - These include tools like micrometers, calipers, and gauges that require precise calibration to guarantee accurate measurements.

- Testing Devices - Equipment such as multimeters, oscilloscopes, and pressure testers need documented calibration to maintain reliable testing results.

- Process Control Instruments - Devices like temperature controllers, flow meters, and pH meters demand calibration records to ensure consistent process monitoring and control.

Steps to Create an Effective Calibration Record Form

Start by identifying all essential information fields such as equipment details, calibration dates, technician names, and measurement results to ensure comprehensive data collection. Design the form with clear labels and organized sections to facilitate easy entry and review of calibration data. Incorporate validation rules and space for comments to maintain accuracy and provide context for any discrepancies observed during the calibration process.

Essential Fields in a Calibration Record Template

An Equipment Calibration Record Form Template includes essential fields such as equipment identification, calibration date, and the technician's name to ensure accurate tracking. Recording the calibration results and the acceptance criteria helps maintain compliance with quality standards. Including a section for remarks or discrepancies supports effective equipment management and troubleshooting.

Best Practices for Maintaining Calibration Records

Equipment Calibration Record Form Templates are essential for accurately documenting calibration activities and ensuring equipment reliability.

Maintaining clear and detailed calibration records helps track equipment performance over time and supports compliance with industry standards. Best practices include recording dates, technician details, calibration results, and any corrective actions.

Digital vs. Paper Calibration Record Forms

Equipment calibration record form templates are essential tools for maintaining accurate and reliable measurement data. Digital calibration record forms offer enhanced data management, easy retrieval, and automated alerts compared to traditional paper forms.

Digital forms improve efficiency and reduce errors by enabling real-time updates and secure storage.