A machine maintenance report form documents the condition, repairs, and servicing of equipment to ensure operational efficiency. It includes key details such as machine identification, maintenance activities performed, and any issues detected during inspection. This structured record helps track maintenance history and schedules, preventing unexpected breakdowns and costly downtime.

Machine Maintenance Report Form Sample PDF Viewer

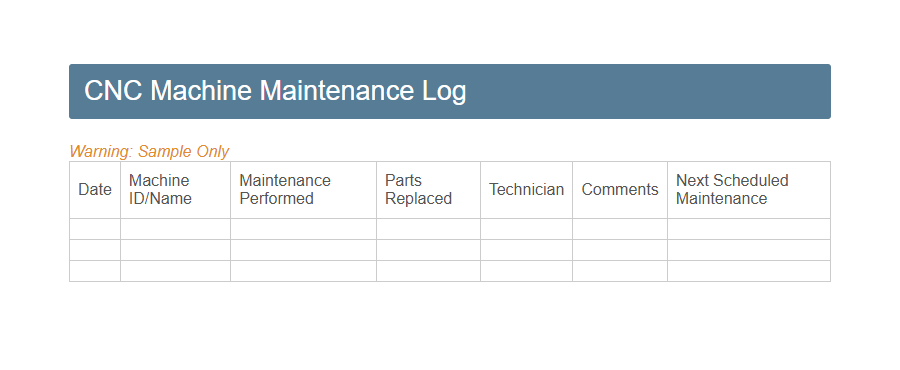

Image example of Machine Maintenance Report Form:

Machine Maintenance Report Form Samples

CNC Machine Maintenance Log Template - PDF - HTML

Preventive Maintenance Checklist for HVAC Systems - PDF - HTML

Injection Molding Machine Service Report - PDF - HTML

Industrial Pump Inspection Report Form - PDF - HTML

Conveyor Belt Maintenance Record Sheet - PDF - HTML

Packaging Machinery Daily Maintenance Form - PDF - HTML

Forklift Routine Maintenance Checklist - PDF - HTML

Hydraulic Press Maintenance Report Template - PDF - HTML

Textile Machinery Downtime and Repair Log - PDF - HTML

Food Processing Equipment Cleaning Report - PDF - HTML

Printing Press Maintenance Tracking Sheet - PDF - HTML

Medical Imaging Equipment Service Checklist - PDF - HTML

Robotics Arm Preventive Maintenance Form - PDF - HTML

Introduction to Machine Maintenance Report Forms

A Machine Maintenance Report Form is a vital document used to record the details of routine inspections, repairs, and servicing of machinery. It helps in tracking the performance and condition of equipment to prevent unexpected breakdowns and extend machine lifespan. This form ensures consistent communication between maintenance teams and management for efficient machine upkeep.

Importance of Regular Machine Maintenance

Regular machine maintenance ensures optimal performance and extends the lifespan of equipment. It helps identify potential issues early, preventing costly breakdowns and downtime. Consistent upkeep improves safety for operators and maintains production efficiency.

Key Components of a Maintenance Report Form

A Machine Maintenance Report Form is essential for documenting the condition and servicing details of machinery.

This form typically includes key components such as machine identification, maintenance date, and technician details. It also records the type of maintenance performed, parts replaced, and any observed issues or recommendations for future repairs.

Types of Machine Maintenance Activities

What are the common types of machine maintenance activities? Machine maintenance activities typically include preventive, corrective, predictive, and condition-based maintenance. Each type plays a crucial role in ensuring machinery operates efficiently and reduces downtime.

Step-by-Step Guide to Completing the Form

A Machine Maintenance Report Form is essential for documenting the condition and servicing of machinery. It helps track repairs, schedule future maintenance, and ensure operational efficiency.

Follow these steps to complete the form accurately and efficiently.

Begin by entering the machine identification details, including the model number, serial number, and location. Record the date and time of the maintenance activity to maintain an accurate timeline.

Describe the maintenance performed in detail, specifying whether it was routine inspection, repair, or replacement of parts.

Note any issues found during the inspection and the corrective actions taken. Include information about the technician who performed the maintenance for accountability.

Verify that all sections of the form are completed clearly and legibly before submission.

Common Issues Identified in Maintenance Reports

Machine maintenance reports frequently highlight recurring issues that affect equipment performance and longevity. Identifying these common problems helps streamline repair processes and improve machine reliability.

- Wear and Tear - Components such as belts, gears, and bearings often show signs of degradation due to regular use.

- Lubrication Problems - Insufficient or contaminated lubrication leads to increased friction and overheating in moving parts.

- Electrical Faults - Faulty wiring or connections frequently cause operational failures and unexpected shutdowns.

Tracking these issues enables maintenance teams to prioritize interventions and minimize downtime effectively.

Benefits of Using Standardized Report Forms

Using standardized machine maintenance report forms ensures consistent and accurate documentation across all maintenance activities. This uniformity enhances communication and facilitates efficient tracking of machine performance and issues.

- Improves data accuracy - Standardized forms reduce errors by guiding technicians to provide complete and relevant information.

- Enhances communication - Consistent reporting formats make it easier for teams to understand and act on maintenance needs promptly.

- Enables better decision-making - Reliable data collected through standardized forms supports effective analysis and timely maintenance planning.

Digital vs. Paper Maintenance Report Forms

Machine maintenance report forms are essential tools for tracking equipment performance and scheduling repairs.

Digital maintenance report forms offer real-time data entry, easier access, and improved accuracy compared to traditional paper forms. Paper forms, while simple to use, often lead to lost documents and slower processing times.

Tips for Effective Maintenance Documentation

Accurate and clear machine maintenance reports improve equipment reliability and reduce downtime. Consistent documentation helps track issues and plan preventive actions efficiently.

- Be detailed - Record specific details about the maintenance performed to ensure clarity and usefulness for future reference.

- Use standardized formats - Employ consistent templates to make information easy to read and compare across different reports.

- Include timestamps - Document exact dates and times of maintenance activities to enable precise tracking and scheduling.