A Process Deviation Report Form is essential for documenting any variations from established procedures, helping organizations maintain quality control and regulatory compliance. This form typically includes fields for describing the deviation, its impact, root causes, and corrective actions taken. Clear and detailed examples of completed forms can guide teams in accurately reporting and addressing process deviations.

Process Deviation Report Form Sample PDF Viewer

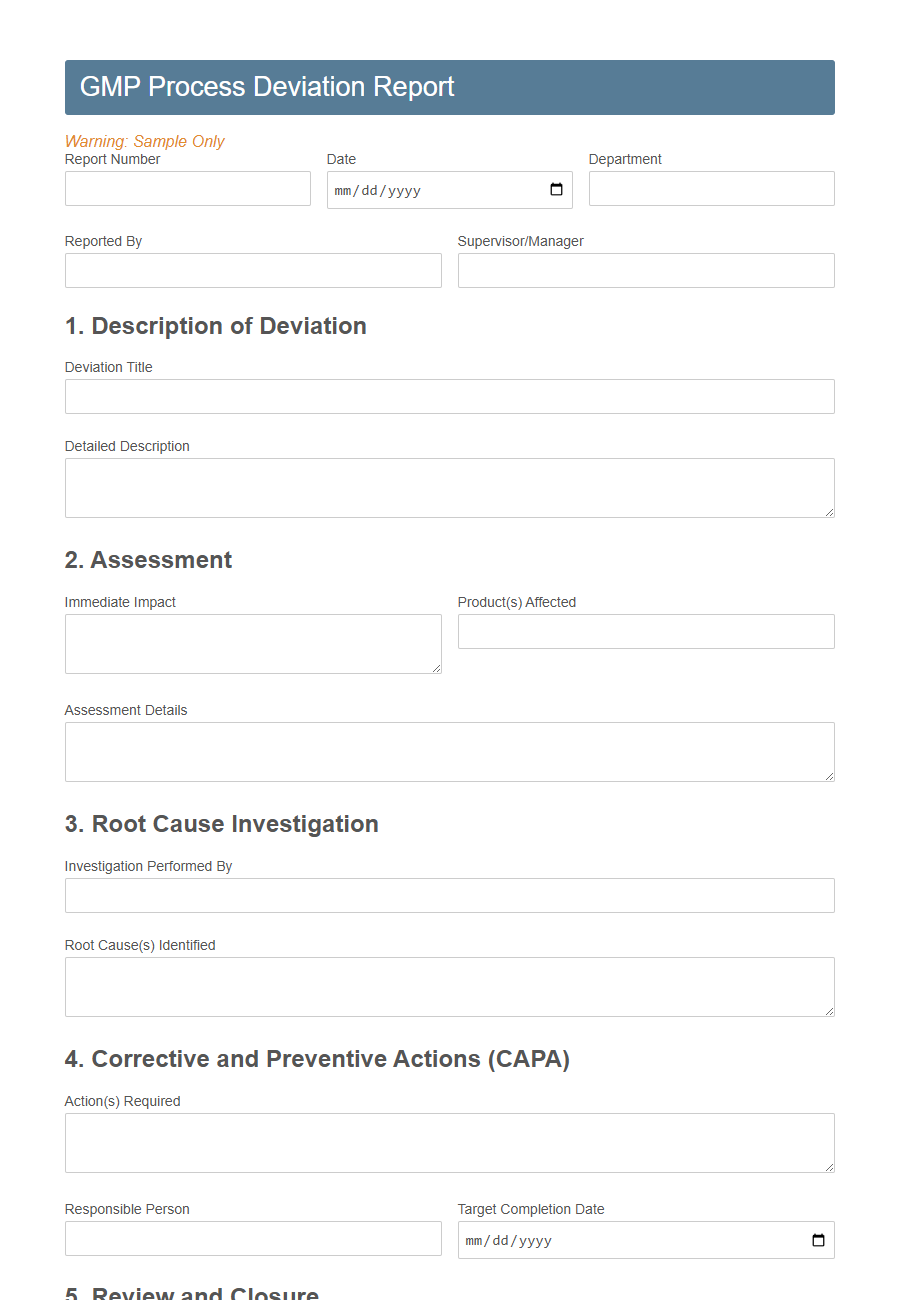

Image example of Process Deviation Report Form:

Process Deviation Report Form Samples

GMP Process Deviation Report Template - PDF - HTML

Manufacturing Deviation Documentation Form - PDF - HTML

Pharmaceutical Process Nonconformance Report - PDF - HTML

QC Laboratory Deviation Notification Form - PDF - HTML

Clinical Trial Protocol Deviation Report - PDF - HTML

Medical Device Process Deviation Template - PDF - HTML

Biotech Batch Process Deviation Form - PDF - HTML

API Production Deviation Report Sheet - PDF - HTML

SOP Deviation Documentation Template - PDF - HTML

Aseptic Process Deviation Log - PDF - HTML

Raw Material Handling Deviation Report - PDF - HTML

Sterile Manufacturing Deviation Form - PDF - HTML

Equipment Malfunction Deviation Record - PDF - HTML

Introduction to Process Deviation Report Forms

A Process Deviation Report Form is a critical document used to record any variations from standard operating procedures during a process.

This form helps identify and document deviations to ensure proper analysis and corrective actions. It supports continuous improvement by capturing detailed information about the nature and impact of the deviation.

Importance of Documenting Process Deviations

Documenting process deviations is essential for maintaining quality and compliance within any operational framework. Accurate records help identify patterns and prevent recurrence.

- Enhances Accountability - Documenting deviations ensures responsible parties are identified and corrective actions are tracked.

- Facilitates Root Cause Analysis - Detailed records support thorough investigations to uncover underlying issues.

- Supports Continuous Improvement - Data from deviation reports guides process enhancements and minimizes future risks.

Consistent documentation of process deviations strengthens operational integrity and drives sustained performance improvements.

Key Components of a Process Deviation Report Form

A Process Deviation Report Form includes key components such as the description of the deviation, specifying the nature and impact of the process anomaly. It requires detailed information about the root cause analysis to identify the source of the deviation accurately. The form also captures corrective and preventive actions to address the issue and prevent future occurrences effectively.

Common Reasons for Process Deviations

Process Deviation Report Forms help identify and document variations from standard procedures in manufacturing or service operations.

Common reasons for process deviations include human error, equipment malfunctions, and incorrect material usage. Environmental factors and inadequate training also contribute significantly to these deviations.

Step-by-Step Guide to Filling Out the Form

Begin by accurately entering the basic information, such as the date, department, and the person's name reporting the deviation. Clearly describe the nature of the deviation, including specific details about the process step involved and any equipment or materials affected. Complete the form by outlining corrective actions taken, root cause analysis, and signing off for verification to ensure proper documentation and follow-up.

Roles and Responsibilities in Deviation Reporting

The Process Deviation Report Form serves as a critical tool for documenting any divergence from standard operating procedures. It ensures clear communication and accountability throughout the deviation handling process.

Personnel must promptly identify and report deviations, while supervisors are responsible for reviewing and approving the reports to initiate corrective actions.

Best Practices for Effective Deviation Documentation

Accurate and timely completion of Process Deviation Report Forms ensures clear communication and swift resolution of issues. Consistent documentation supports quality control and continuous improvement initiatives.

- Be Clear and Concise - Use precise language to describe the deviation without ambiguity to facilitate understanding and corrective actions.

- Include All Relevant Details - Document the cause, impact, and immediate actions taken to provide a comprehensive overview of the deviation.

- Review and Approve Promptly - Ensure the report is reviewed and signed off by appropriate personnel to maintain accountability and expedite resolution.

Review and Approval Workflow

The Process Deviation Report Form ensures systematic documentation and tracking of any deviations from established procedures. The Review and Approval Workflow guarantees that all deviations are evaluated and authorized by the appropriate personnel before corrective actions are implemented.

- Submission of Report - The form is completed by the individual identifying the deviation and submitted to the designated review team.

- Evaluation by Review Team - The review team assesses the deviation's impact, determining root causes and required corrective measures.

- Final Approval - Authorized personnel approve or reject the report, ensuring compliance with organizational standards before closure.

Corrective and Preventive Actions (CAPA)

What is the purpose of a Process Deviation Report Form in managing CAPA? It documents process deviations to identify root causes and implement corrective and preventive actions. This ensures continuous improvement and reduces recurrence of issues.