A production planning schedule request form organizes manufacturing tasks and resource allocation efficiently. It streamlines communication between departments, ensuring timely updates and accurate scheduling. Using standardized examples helps businesses optimize workflow and meet project deadlines effectively.

Production Planning Schedule Request Form Sample PDF Viewer

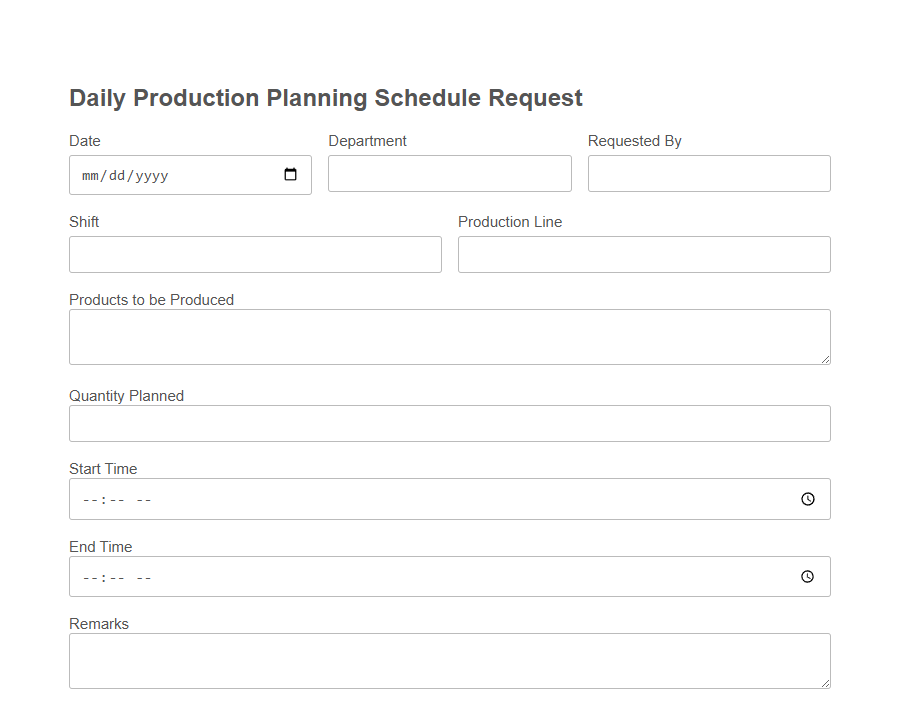

Image example of Production Planning Schedule Request Form:

Production Planning Schedule Request Form Samples

Daily Production Planning Schedule Request Template - PDF - HTML

Weekly Production Planning Schedule Request Form - PDF - HTML

Custom Product Batch Planning Request Template - PDF - HTML

Shift-based Production Schedule Request Form - PDF - HTML

Prototype Production Planning Request Template - PDF - HTML

Small-Scale Manufacturing Schedule Request Form - PDF - HTML

Emergency Production Rescheduling Request Template - PDF - HTML

Seasonal Production Planning Request Form - PDF - HTML

Packaging Line Production Schedule Request Template - PDF - HTML

Raw Material-Specific Production Planning Request Form - PDF - HTML

Machine Downtime Production Reschedule Request Template - PDF - HTML

New Product Launch Planning Schedule Request Form - PDF - HTML

Maintenance Window Production Planning Request Template - PDF - HTML

Just-in-Time Production Schedule Request Form - PDF - HTML

Bulk Order Production Planning Schedule Request Template - PDF - HTML

Introduction to Production Planning Schedule Request Form

The Production Planning Schedule Request Form is a crucial tool used to organize manufacturing activities efficiently. It helps ensure that all production requirements are clearly communicated and scheduled.

- Purpose - This form facilitates the coordination of resources, materials, and timelines for production tasks.

- Structure - It typically includes fields for product details, quantity, deadlines, and special instructions.

- Benefit - Using this form reduces delays and improves overall workflow management in the production process.

Importance of a Structured Request Form in Production Planning

A structured request form in production planning ensures clear communication of requirements, reducing errors and misunderstandings. It allows for efficient allocation of resources by providing detailed and consistent information. Such a form streamlines the planning process, leading to timely production and increased overall productivity.

Key Components of a Production Planning Schedule Request Form

The Production Planning Schedule Request Form includes key components such as order details, including product specifications and quantities required. It also features a timeline section that outlines the desired start and completion dates for production. Resource allocation information, specifying labor, machinery, and materials needed, is essential for efficient scheduling and workflow management.

Steps to Complete the Request Form Effectively

Completing a Production Planning Schedule Request Form accurately is essential for smooth manufacturing operations. Clear and detailed information ensures efficient resource allocation and timely production.

- Gather Required Data - Collect all necessary details such as product specifications, quantities, and deadlines before starting the form.

- Fill in Accurate Information - Enter precise and complete data to avoid scheduling errors and production delays.

- Review and Submit - Double-check all entries for correctness and submit the form to the planning team for processing.

Common Challenges in Using Schedule Request Forms

What are common challenges in using production planning schedule request forms? Many users struggle with incomplete or inaccurate information, causing delays and errors in scheduling. Miscommunication between departments often leads to repeated submissions and confusion.

Digital vs. Manual Production Planning Request Forms

The Production Planning Schedule Request Form is essential for organizing manufacturing workflows efficiently. Digital and manual forms offer distinct advantages and challenges in managing production schedules.

- Digital Production Planning Request Forms - These forms enable real-time updates and automated notifications, reducing errors and improving communication across departments.

- Manual Production Planning Request Forms - Physical forms allow for immediate accessibility in environments with limited technology but can lead to delays and misplacement.

- Comparison of Efficiency - Digital forms streamline data entry and retrieval, whereas manual forms often require additional time for processing and filing.

Choosing between digital and manual request forms depends on the operational needs and technological capabilities of the production facility.

Optimizing Workflow with Schedule Request Forms

Production planning schedule request forms streamline the coordination of manufacturing tasks.

These forms provide a clear structure for submitting and prioritizing production needs, reducing delays and miscommunication. Implementing schedule request forms optimizes workflow by ensuring resources are allocated efficiently and deadlines are met consistently.

Best Practices for Managing Production Planning Requests

A Production Planning Schedule Request Form streamlines communication between departments by clearly outlining production needs and timelines. It ensures accurate resource allocation and helps prevent scheduling conflicts.

Establishing standardized fields and guidelines within the form promotes consistency and reduces errors in submitting production requests.

Integrating Request Forms with Enterprise Resource Planning (ERP) Systems

Integrating Production Planning Schedule Request Forms with Enterprise Resource Planning (ERP) systems enhances manufacturing efficiency and accuracy.

It streamlines data flow between departments, allowing real-time updates on production schedules and resource availability. This integration reduces manual errors and accelerates decision-making processes.