Supplier evaluation forms streamline the assessment of vendor performance by providing structured criteria for quality, delivery, and cost efficiency. These forms facilitate informed decision-making, enabling businesses to maintain strong supplier relationships and drive continuous improvement. Incorporating clear metrics and measurable data points ensures consistency and objectivity throughout the evaluation process.

Supplier Evaluation Form Sample PDF Viewer

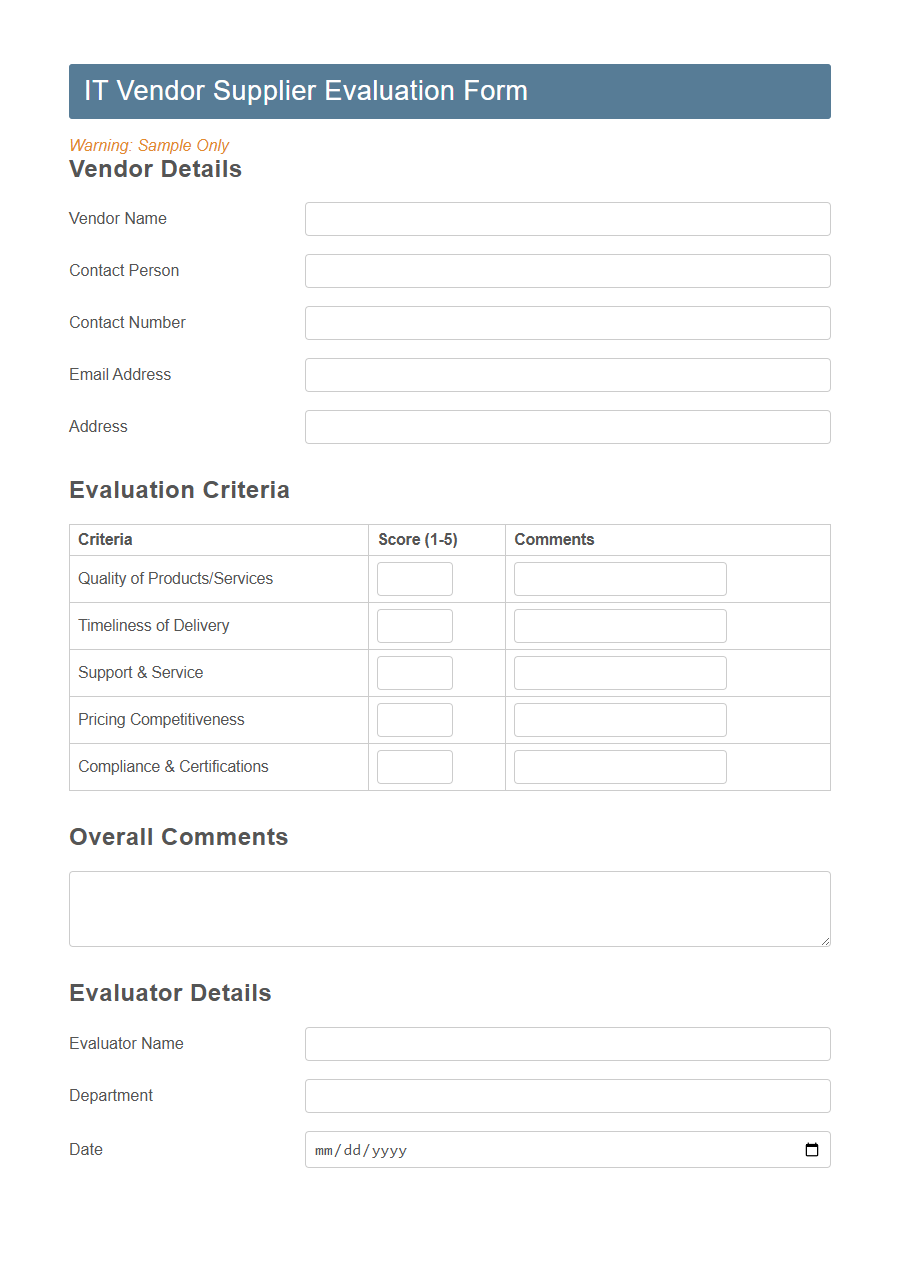

Image example of Supplier Evaluation Form:

Supplier Evaluation Form Samples

IT Vendor Supplier Evaluation Form - PDF - HTML

Healthcare Supplier Performance Evaluation Template - PDF - HTML

Eco-Friendly Packaging Supplier Assessment Form - PDF - HTML

Restaurant Food Supplier Quality Evaluation Sheet - PDF - HTML

Construction Material Supplier Compliance Checklist - PDF - HTML

Pharmaceutical Raw Material Supplier Review Form - PDF - HTML

Small Business Local Supplier Evaluation Template - PDF - HTML

Fashion Retail Fabric Supplier Scoring Sheet - PDF - HTML

Automotive Parts Supplier Risk Assessment Form - PDF - HTML

Electronics Component Supplier Audit Template - PDF - HTML

Organic Food Supplier Certification Evaluation - PDF - HTML

Industrial Equipment Supplier Capability Checklist - PDF - HTML

Hospitality (Hotel) Service Supplier Evaluation Form - PDF - HTML

Renewable Energy Supplier Vetting Template - PDF - HTML

Laboratory Chemicals Supplier Qualification Form - PDF - HTML

Introduction to Supplier Evaluation

Supplier evaluation is a critical process to assess and ensure the quality and reliability of vendors. It helps organizations select the best suppliers to meet their operational and strategic needs.

- Purpose - To systematically review supplier performance and capabilities.

- Criteria - Involves assessing factors such as quality, delivery, cost, and service.

- Outcome - Supports informed decision-making for supplier selection and ongoing partnerships.

Effective supplier evaluation enhances supply chain efficiency and reduces risks associated with vendor management.

Importance of a Supplier Evaluation Form

A Supplier Evaluation Form is essential for systematically assessing a supplier's performance and reliability. It helps organizations maintain quality standards and optimize their supply chain decisions.

- Ensures Quality Consistency - It provides a structured way to measure suppliers against predefined criteria to maintain product and service quality.

- Facilitates Risk Management - Evaluation forms identify potential risks related to supplier performance, enabling proactive mitigation strategies.

- Supports Strategic Decision-Making - The collected data guides procurement teams in selecting and retaining suppliers who contribute to long-term business goals.

Key Components of a Supplier Evaluation Form

A Supplier Evaluation Form typically includes essential components such as supplier identification, product quality assessment, and delivery performance. It also features criteria like pricing, compliance with specifications, and communication efficiency to ensure a comprehensive evaluation. These key components help organizations maintain high standards and foster strong supplier relationships.

Criteria for Assessing Suppliers

What criteria should be used to assess suppliers effectively? Evaluating suppliers involves examining factors such as quality, delivery performance, and price competitiveness. Consistent reliability and compliance with industry standards are also crucial elements in supplier assessment.

Steps in the Supplier Evaluation Process

The supplier evaluation process begins with identifying criteria that align with your business needs and project requirements. Gathering relevant data about potential suppliers through questionnaires, past performance, and financial stability is essential to form a comprehensive assessment.

Next, systematically scoring and ranking suppliers helps in comparing their capabilities and reliability efficiently.

Customizing the Evaluation Form for Your Business

Customizing a supplier evaluation form ensures it aligns perfectly with your business needs and priorities.

By tailoring the criteria to reflect your industry standards and specific project requirements, you gain more relevant insights into supplier performance. This approach enhances decision-making and fosters stronger supplier relationships.

Common Mistakes to Avoid in Supplier Evaluation

A common mistake in supplier evaluation is relying solely on price, which can overlook quality and reliability factors. Failing to gather comprehensive data or feedback from multiple departments may lead to biased or incomplete assessments. Ignoring the importance of regular reviews can result in outdated evaluations that do not reflect current supplier performance.

Leveraging Technology in Supplier Evaluation

Leveraging technology in a Supplier Evaluation Form enhances accuracy and efficiency in assessing supplier performance.

Digital tools enable real-time data collection and analysis, streamlining the evaluation process. Automated scoring systems reduce human error and provide consistent, objective supplier ratings.

Reviewing and Updating Supplier Evaluation Forms

Regularly reviewing and updating Supplier Evaluation Forms ensures that the assessment criteria remain relevant and effective. This process helps maintain accurate supplier performance records and supports informed decision-making.

- Reviewing Criteria - Assess if the current evaluation metrics align with the company's procurement goals and market changes.

- Incorporating Feedback - Integrate input from stakeholders and suppliers to improve the evaluation process and address any gaps.

- Updating Forms - Revise the form structure and content periodically to reflect new standards, compliance requirements, and business priorities.