Raw material inspection forms play a vital role in ensuring product quality by documenting the evaluation of incoming materials. These forms typically include criteria such as material specifications, visual checks, and compliance standards. Accurate and thorough documentation helps prevent defects and maintain consistency throughout the manufacturing process.

Raw Material Inspection Form Sample PDF Viewer

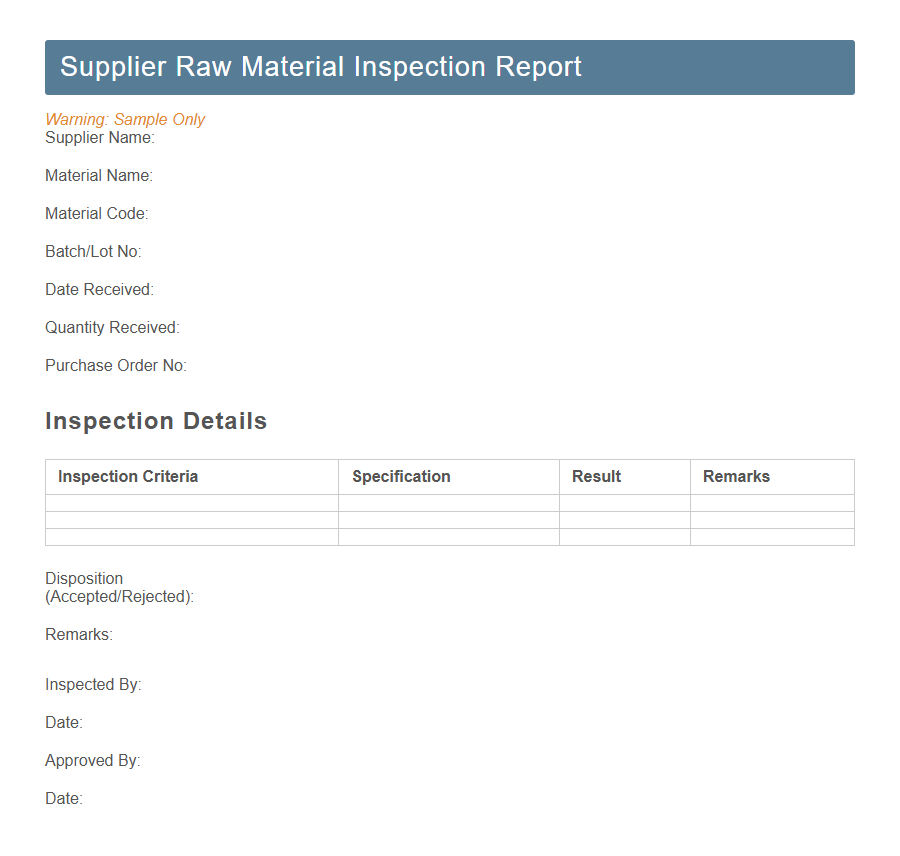

Image example of Raw Material Inspection Form:

Raw Material Inspection Form Samples

Supplier Raw Material Inspection Report - PDF - HTML

Incoming Raw Material Quality Checklist - PDF - HTML

Raw Material Receiving Inspection Log - PDF - HTML

Raw Material Conformance Verification Sheet - PDF - HTML

Raw Material Defect Tracking Template - PDF - HTML

Raw Material Batch Inspection Form - PDF - HTML

Raw Material Visual Inspection Record - PDF - HTML

Raw Material Dimensional Inspection Worksheet - PDF - HTML

Raw Material Chemical Composition Inspection Sheet - PDF - HTML

Raw Material Non-Conformance Report - PDF - HTML

Raw Material Traceability Documentation Template - PDF - HTML

Raw Material Moisture Content Test Form - PDF - HTML

Raw Material Packaging Inspection Checklist - PDF - HTML

Introduction to Raw Material Inspection Forms

Raw Material Inspection Forms are essential documents used to verify the quality and specifications of incoming materials. These forms help ensure that raw materials meet the required standards before entering the production process.

- Purpose - To document and confirm the quality and compliance of raw materials upon receipt.

- Components - Typically include material identification, inspection criteria, and acceptance or rejection status.

- Importance - Prevents defects and inconsistencies by catching material issues early in the supply chain.

Importance of Raw Material Inspection

Why is raw material inspection crucial in manufacturing? It ensures that incoming materials meet quality standards before production begins. This process prevents defects, reduces waste, and maintains overall product integrity.

Key Components of a Raw Material Inspection Form

A Raw Material Inspection Form includes key components such as material identification, supplier details, and batch numbers to ensure traceability. It captures inspection criteria like appearance, dimensions, and compliance with specifications to verify quality before production. The form also documents inspection results, acceptance status, and inspector's signature to maintain accountability and quality control.

Types of Raw Materials Inspected

The Raw Material Inspection Form is used to document the assessment of various raw materials before production begins.

Types of raw materials inspected include metals, plastics, chemicals, textiles, and electronic components. Each type undergoes specific quality checks to ensure compliance with industry standards and project requirements.

Essential Information Captured in the Form

The Raw Material Inspection Form captures essential information such as material identification, supplier details, and batch numbers to ensure traceability. It records physical characteristics, dimensions, and compliance with specified quality standards. The form also documents inspection results, including any defects or deviations, enabling effective quality control and decision-making.

Inspection Criteria and Standards

The Raw Material Inspection Form ensures quality control by documenting the evaluation of incoming materials against specific criteria. Inspections focus on parameters such as material type, dimensions, appearance, and compliance with technical specifications. Standards referenced include ISO, ASTM, and company-specific quality requirements, guaranteeing materials meet production and safety needs before use.

Documentation and Traceability

The Raw Material Inspection Form serves as a critical document ensuring all incoming materials meet specified quality standards. It captures detailed information about the material's origin, specifications, and inspection results for effective quality control.

This form enhances traceability by maintaining a clear record of each batch of raw materials used in production.

Common Issues Detected During Inspection

Raw Material Inspection Forms are essential for identifying defects and inconsistencies before production begins. Common issues detected during inspection help ensure quality standards are maintained throughout the manufacturing process.

- Incorrect Dimensions - Materials often fail to meet specified size requirements, impacting fit and function.

- Contamination - Presence of dirt, oil, or foreign particles can compromise material quality and safety.

- Surface Defects - Scratches, cracks, and other surface imperfections are frequently identified and must be addressed before use.

Digital vs. Paper-Based Inspection Forms

Raw Material Inspection Forms are essential for ensuring material quality and compliance during production. Choosing between digital and paper-based forms impacts efficiency, accuracy, and data management.

- Digital Inspection Forms - Enhance data accuracy through real-time input and automated error checking.

- Paper-Based Inspection Forms - Provide a straightforward, low-tech solution but are prone to human error and data loss.

- Data Accessibility - Digital forms allow instant access and integration with other systems, unlike paper forms which require manual handling and storage.

Transitioning to digital inspection forms improves quality control and streamlines the inspection workflow significantly.