Manufacturing defect submission forms streamline the process of reporting product issues, ensuring efficient communication between customers and manufacturers. These forms typically include detailed fields for defect description, batch numbers, and images to support claims. Clear examples help users accurately complete the form, speeding up resolution and improving product quality control.

Manufacturing Defect Submission Form Sample PDF Viewer

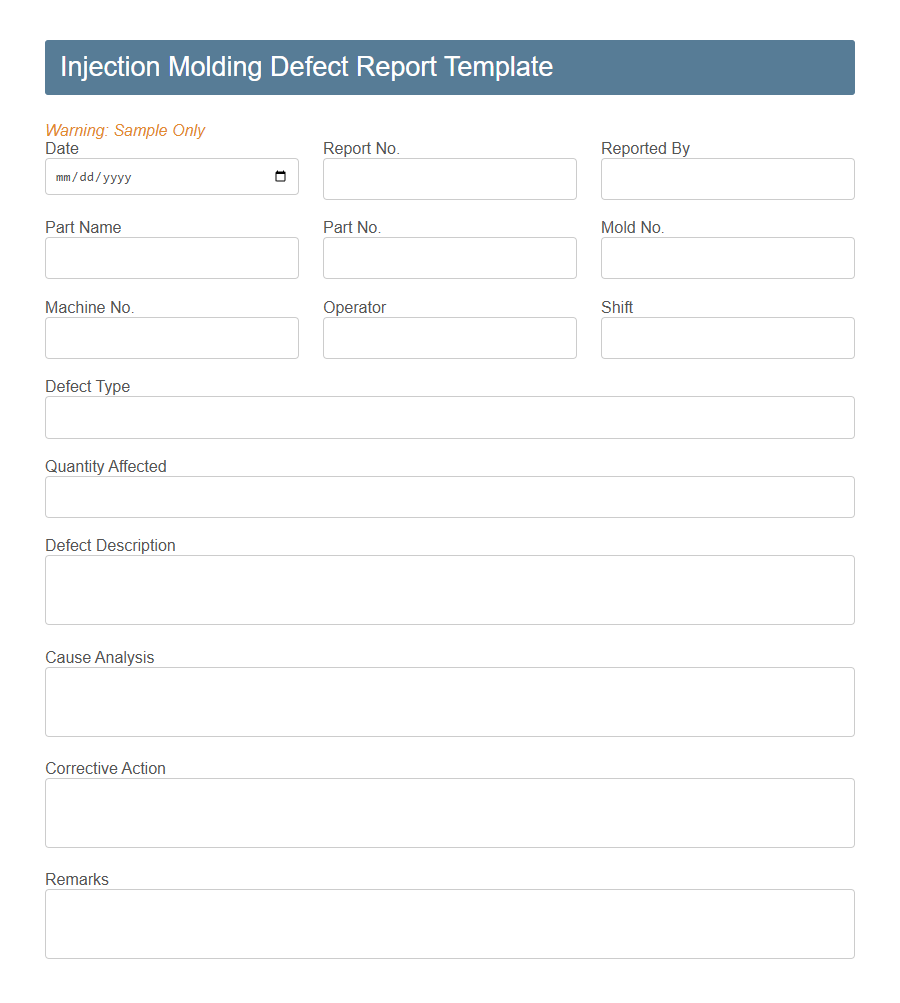

Image example of Manufacturing Defect Submission Form:

Manufacturing Defect Submission Form Samples

Injection Molding Defect Report Template - PDF - HTML

CNC Machining Error Logging Sheet - PDF - HTML

Sheet Metal Fabrication Defect Submission Form - PDF - HTML

PCB Assembly Defect Documentation Template - PDF - HTML

Powder Coating Flaw Report Form - PDF - HTML

Food Processing Contaminant Incident Report - PDF - HTML

Pharmaceutical Batch Deviation Submission Template - PDF - HTML

Textile Weaving Defect Notification Form - PDF - HTML

Automotive Parts Paint Defect Report Sheet - PDF - HTML

3D Printing Error Submission Form - PDF - HTML

Cleanroom Product Nonconformance Template - PDF - HTML

Bottling Line Seal Failure Report - PDF - HTML

Glass Manufacturing Crack Defect Submission - PDF - HTML

Introduction to Manufacturing Defect Submission

A Manufacturing Defect Submission Form is a crucial document used to report and track defects identified during the production process. This form ensures that issues are properly documented, analyzed, and addressed to maintain product quality and safety.

Using this form helps streamline communication between manufacturing teams and quality control departments to resolve defects efficiently.

Importance of Reporting Defects

Reporting defects through a Manufacturing Defect Submission Form is essential to maintain product quality and safety.

Timely and accurate defect reporting helps manufacturers identify issues early, preventing potential failures and costly recalls. It ensures continuous improvement in the production process, protecting both the company's reputation and the end users.

Who Should Use the Submission Form

The Manufacturing Defect Submission Form is intended for individuals who have identified a flaw or error in a product during or after the production process. Quality control personnel, production staff, and inspectors should use this form to report any defects promptly. This ensures that manufacturing issues are documented accurately for timely resolution and improvement.

Key Information Required

The Manufacturing Defect Submission Form requires detailed product information, including model number, batch code, and date of manufacture. Clear descriptions of the defect, accompanied by photographic evidence, are essential for accurate assessment. Contact details of the submitter are necessary to facilitate follow-up and resolution.

How to Access the Submission Form

To report a manufacturing defect, you need to access the Manufacturing Defect Submission Form available online.

Visit the official company website and navigate to the support or customer service section. The form can usually be found under product issues or quality assurance categories for easy submission.

Step-by-Step Submission Process

The Manufacturing Defect Submission Form streamlines reporting product issues for efficient resolution. Following the step-by-step submission process ensures accurate and complete information is provided for quick assessment.

- Gather Product Information - Collect all relevant details about the product, including model number and batch code, to identify the item precisely.

- Describe the Defect - Clearly explain the nature of the defect with specific symptoms or problems observed during use.

- Attach Supporting Evidence - Upload photos, videos, or documents that illustrate the defect to support your submission effectively.

- Fill in Contact Details - Provide accurate contact information to enable follow-up communication from the manufacturer or service team.

- Submit the Form - Review all entered information carefully before submitting the form to initiate the defect investigation process.

Supporting Documents and Evidence

Supporting documents and evidence are essential for validating a manufacturing defect claim. Properly organized materials help streamline the investigation process and ensure accurate resolution.

- Photographic Evidence - Clear images of the defect illustrate the issue visually and provide concrete proof.

- Purchase Records - Receipts or invoices confirm the product's origin and purchase date.

- Inspection Reports - Detailed assessments from quality control or third-party inspections highlight specific defects.

Including comprehensive supporting documents increases the likelihood of a successful manufacturing defect submission.

Common Issues When Submitting

Submitting a Manufacturing Defect Submission Form can often present challenges that delay processing. Understanding common issues helps streamline the submission and ensures accurate defect reporting.

- Incomplete Information - Missing details such as product serial numbers or defect descriptions hinder proper evaluation.

- Incorrect Documentation - Providing inaccurate or irrelevant documents can cause confusion and slow down resolution.

- Poor Quality Images - Blurry or unclear photos of defects fail to demonstrate the problem effectively, leading to potential rejection.

Follow-Up and Resolution Timeline

How does the Manufacturing Defect Submission Form ensure timely follow-up and resolution? The form includes clear fields for tracking response dates and responsible personnel. This structure promotes accountability and speeds up the defect resolution process.