A line clearance checklist form ensures all equipment and work areas are free from contaminants or unauthorized items before production begins. This tool helps maintain safety standards and product quality by verifying cleanliness and proper organization. Examples of checklist items include equipment cleaning status, removal of obsolete materials, and verification of proper tool placement.

Line Clearance Checklist Form Sample PDF Viewer

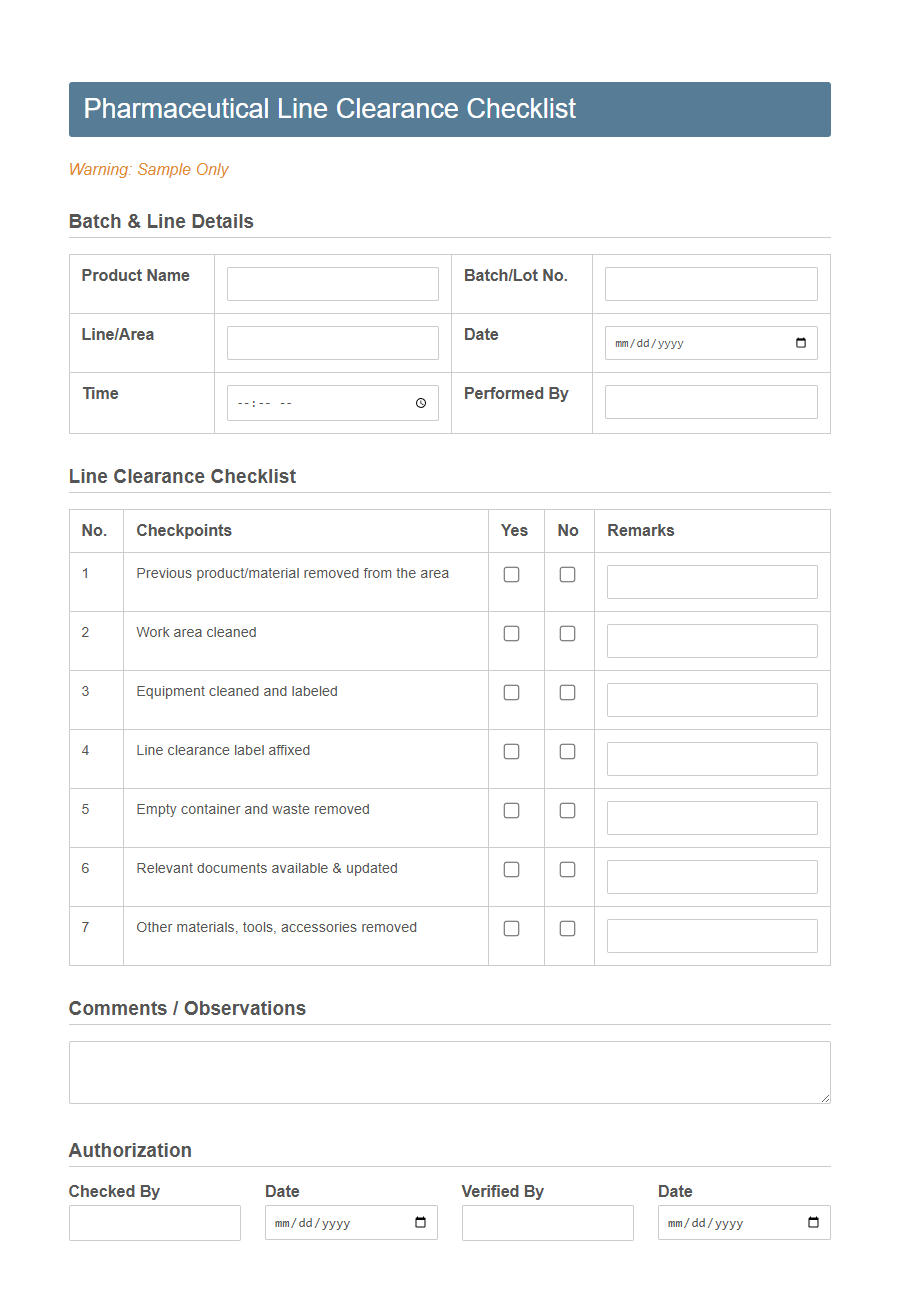

Image example of Line Clearance Checklist Form:

Line Clearance Checklist Form Samples

Pharmaceutical Line Clearance Checklist Template - PDF - HTML

Food Production Line Clearance Form - PDF - HTML

GMP Manufacturing Line Clearance Checklist - PDF - HTML

Warehouse Picking Area Line Clearance Template - PDF - HTML

Cosmetic Production Line Clearance Checklist - PDF - HTML

Packaging Line Clearance Record Form - PDF - HTML

Cleanroom Line Clearance Checklist Template - PDF - HTML

Medical Device Assembly Line Clearance Form - PDF - HTML

Electronics Manufacturing Line Clearance Checklist - PDF - HTML

Sterile Processing Line Clearance Form - PDF - HTML

Beverage Bottling Line Clearance Checklist - PDF - HTML

Cannabis Processing Line Clearance Template - PDF - HTML

Dairy Processing Line Clearance Checklist - PDF - HTML

Paint Manufacturing Line Clearance Form - PDF - HTML

Nutraceutical Production Line Clearance Checklist - PDF - HTML

Introduction to Line Clearance Checklist Forms

Line Clearance Checklist Forms are essential tools used in manufacturing and production to ensure that equipment is thoroughly cleaned and free of contaminants before switching to a different product or batch. These forms help maintain quality control and prevent cross-contamination.

- Purpose - To verify that all necessary cleaning and preparation tasks are completed before starting a new production run.

- Compliance - Ensures adherence to safety and quality standards by documenting the clearance process.

- Accountability - Assigns responsibility by recording who performed and checked each step of the line clearance procedure.

Importance of Line Clearance in Manufacturing

Line clearance is a critical step in manufacturing to ensure product quality and prevent contamination. Using a Line Clearance Checklist Form helps maintain consistent checks and avoids costly production errors.

- Prevents Cross-Contamination - Line clearance verifies that previous materials and tools are removed to avoid mixing different product batches.

- Maintains Product Quality - Ensuring the production line is clean reduces defects and adherence to quality standards.

- Improves Compliance - Following a documented checklist supports regulatory requirements and audit readiness.

Key Components of a Line Clearance Checklist

A Line Clearance Checklist ensures a safe and organized workspace by verifying that all necessary steps are completed before starting a new task or production run.

Key components include verifying the removal of previous materials, ensuring all tools and equipment are clean and in place, and confirming that the workspace is free of any hazards or obstructions.

The checklist should also document visual inspections, approval signatures from responsible personnel, and confirmation that all safety protocols are followed.

Clear identification and segregation of different materials, proper labeling, and verification of machine settings are critical for preventing cross-contamination and operational errors.

Maintaining detailed records through the checklist helps ensure compliance with quality standards and facilitates traceability for audits and reviews.

Regulatory Requirements for Line Clearance

Line Clearance Checklist Forms ensure compliance with regulatory requirements by verifying that work areas are free of unauthorized materials before production begins. These forms help maintain product safety, prevent contamination, and meet industry standards set by regulatory agencies. Proper documentation supports audits and demonstrates adherence to quality control protocols.

Step-by-Step Process for Completing a Line Clearance Checklist

Completing a Line Clearance Checklist ensures that a workspace is free from errors before starting production. This step-by-step guide helps maintain quality and safety standards effectively.

- Prepare the workspace - Remove all materials, tools, and debris from the production area to start with a clean environment.

- Verify equipment settings - Check machines and tools are set according to the required specifications for the new production run.

- Inspect documentation - Confirm that all labels, work orders, and instructions match the new production batch.

Following this process guarantees that the line clearance is thorough and ready for the next operation.

Common Mistakes in Line Clearance Procedures

Common mistakes in line clearance procedures include failing to properly document cleared lines, leading to confusion and potential errors during production. Workers often overlook verifying that all tools and materials are removed, increasing the risk of contamination or equipment damage. Inadequate communication between shifts can result in incomplete line clearance, compromising product quality and safety.

Tips for Effective Line Clearance Implementation

How can you ensure an effective line clearance implementation? Clear communication of the checklist criteria to all team members helps avoid misunderstandings and errors. Regular training sessions reinforce the importance of line clearance and keep everyone updated on best practices.

What role does organization play in line clearance success? Keeping the workspace tidy and well-arranged reduces the risk of contaminants and mistakes during changeovers. Using labeled containers and designated storage areas streamlines the process and saves time.

Why is documentation crucial for line clearance? Accurate completion of the checklist form provides a traceable record of compliance and identifies areas needing improvement. Consistent documentation supports quality control and audit readiness.

How can team collaboration enhance the line clearance process? Involving operators, supervisors, and quality personnel ensures thorough inspection and accountability. Open feedback channels help refine procedures and address challenges promptly.

What importance does timing have in line clearance implementation? Conducting line clearance immediately before production changes minimizes the chance of cross-contamination. Scheduling adequate time for thorough clearance prevents rushed or incomplete checks.

Benefits of Using Digital Line Clearance Checklist Forms

Using digital line clearance checklist forms enhances accuracy by minimizing manual errors and ensuring all necessary steps are thoroughly documented. It streamlines the inspection process, allowing for faster data entry and real-time updates accessible from any device.

These forms improve compliance tracking and enable easy storage and retrieval of records for audits and safety reviews.

Line Clearance Checklist Best Practices

A Line Clearance Checklist ensures a clean and organized workspace before production begins.

Following best practices for the Line Clearance Checklist helps prevent mix-ups, contamination, and production errors. Regularly updating the checklist and training staff enhances compliance and operational efficiency.