Batch production record forms ensure accurate documentation throughout the manufacturing process. These forms capture essential details such as raw materials, processing steps, and quality control checks. Proper use of batch production record forms enhances compliance, traceability, and product consistency.

Batch Production Record Form Sample PDF Viewer

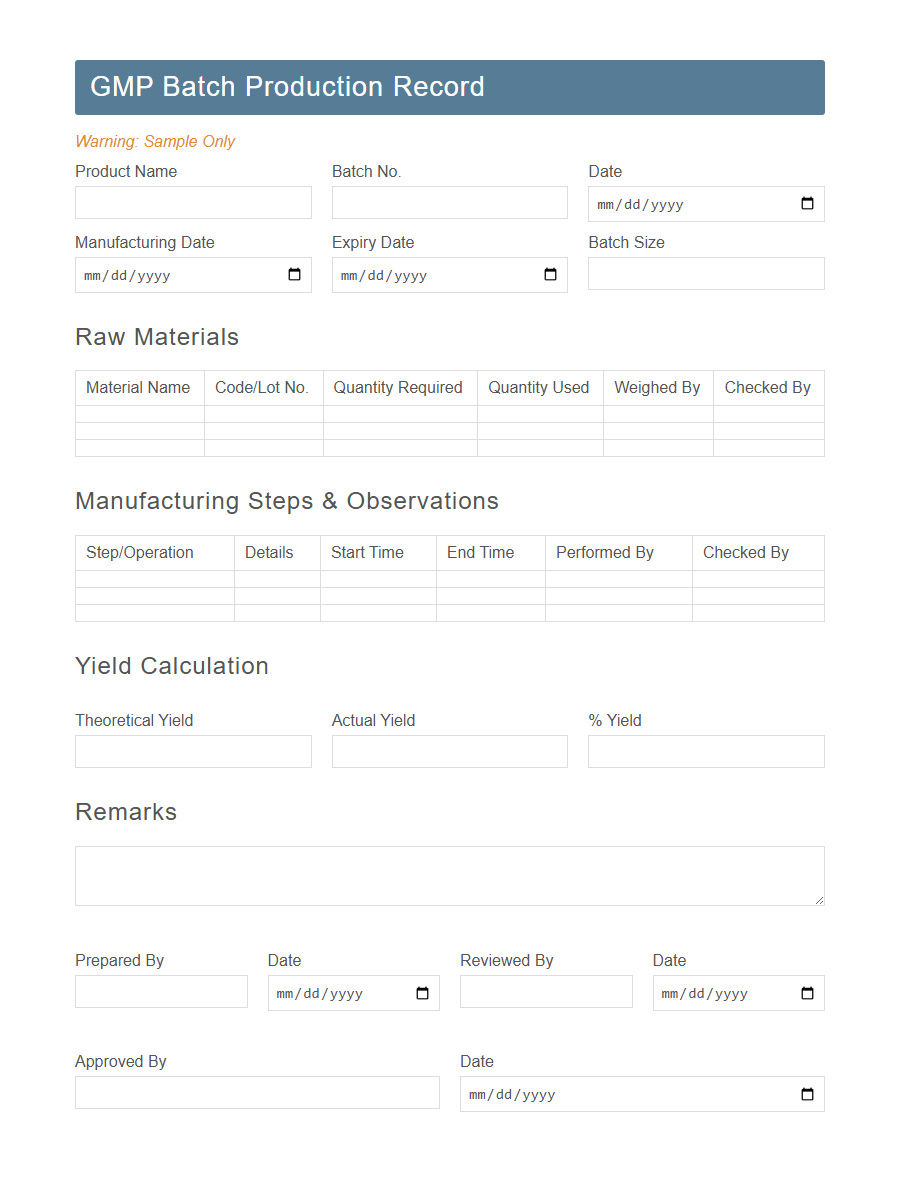

Image example of Batch Production Record Form:

Batch Production Record Form Samples

GMP Batch Production Record Template - PDF - HTML

Pharmaceutical Batch Manufacturing Record - PDF - HTML

Cosmetic Batch Production Sheet - PDF - HTML

Food Production Batch Log Form - PDF - HTML

Chemical Batch Manufacturing Record - PDF - HTML

Medical Device Batch Production Template - PDF - HTML

Herbal Supplement Batch Production Log - PDF - HTML

Sterile Manufacturing Batch Record - PDF - HTML

Compounding Pharmacy Batch Record Sheet - PDF - HTML

Biotech Pilot Batch Record Template - PDF - HTML

Veterinary Product Batch Production Form - PDF - HTML

Nutraceutical Batch Production Log - PDF - HTML

Cannabis Product Batch Record Template - PDF - HTML

Personal Care Product Batch Log Sheet - PDF - HTML

API (Active Pharmaceutical Ingredient) Batch Manufacturing Record - PDF - HTML

Introduction to Batch Production Record Forms

Batch Production Record Forms are essential documents used in manufacturing to ensure consistent product quality and compliance with regulatory standards. They provide a detailed account of the production process for each batch produced.

- Documentation - Captures all critical information related to raw materials, equipment, and processes used during production.

- Traceability - Enables tracking of each batch from raw materials to finished products for quality control and recall purposes.

- Compliance - Ensures adherence to industry regulations and Good Manufacturing Practices (GMP) through systematic record-keeping.

Batch Production Record Forms serve as a vital tool for maintaining transparency and accountability in manufacturing operations.

Importance of Batch Production Record Forms in Manufacturing

Batch Production Record Forms play a critical role in ensuring product consistency and regulatory compliance in manufacturing. These documents provide a detailed account of every step in the production process to maintain quality control.

- Enhances Traceability - Records each ingredient and process detail, enabling full traceability throughout production.

- Ensures Quality Assurance - Provides a documented framework to verify that manufacturing adheres to designated standards.

- Facilitates Regulatory Compliance - Meets industry regulations by maintaining accurate and complete production records.

Key Components of a Batch Production Record Form

What are the key components of a Batch Production Record Form? The form includes detailed information on raw materials, manufacturing processes, and quality control checks. It ensures traceability and consistency in the production of each batch.

Regulatory Requirements for Batch Production Record Forms

Batch Production Record Forms must comply with strict regulatory requirements to ensure product quality and traceability. These forms are essential for documenting each step of the manufacturing process, including raw materials, equipment used, and personnel involved. Regulatory agencies require accurate and complete records to verify compliance with Good Manufacturing Practices (GMP) and to facilitate audits and inspections.

Step-by-Step Guide to Completing a Batch Production Record Form

A Batch Production Record Form ensures accurate documentation of each step in the manufacturing process, maintaining product quality and regulatory compliance. Begin by filling in essential details such as batch number, product name, and production date to establish traceability. Next, record all raw materials used, equipment settings, and personnel involved, followed by detailed notes on each production phase, including any deviations or observations.

Common Mistakes in Batch Production Record Documentation

Batch Production Record Forms are essential for ensuring product quality and regulatory compliance in manufacturing processes. Common mistakes in these documents often include incomplete entries and inaccurate data recording.

Omitting critical information or using illegible handwriting can lead to production delays and regulatory issues.

Best Practices for Maintaining Batch Production Records

Accurate batch production records are essential for quality control and regulatory compliance.

Maintaining clear and detailed documentation helps trace any discrepancies and ensures product consistency. Implement standardized templates to capture all critical production steps and materials used.

Role of Batch Production Record Forms in Quality Assurance

Batch Production Record Forms play a critical role in ensuring product quality and regulatory compliance throughout the manufacturing process. These documents provide detailed, step-by-step records that support traceability and accountability in quality assurance practices.

- Verification - They confirm that each production step adheres to predefined quality standards and protocols, minimizing the risk of errors.

- Traceability - Batch records provide a comprehensive history of the materials, processes, and personnel involved, facilitating effective investigation during quality audits or deviations.

- Consistency - Detailed documentation ensures uniformity across batches, supporting continuous quality improvement and regulatory compliance.

Electronic vs. Paper-Based Batch Production Record Forms

Batch Production Record Forms are essential documents used to track the manufacturing process of products.

Electronic Batch Production Record Forms offer faster data entry, improved accuracy, and easier access compared to traditional paper-based forms. Paper-Based Batch Production Record Forms, while familiar and simple to use, often require more storage space and are prone to human error and data loss.