A calibration record form documents the details and results of equipment calibration processes, ensuring accuracy and compliance with standards. This form typically includes information such as equipment identification, calibration date, methods used, and technician details. Proper use of calibration record forms helps maintain equipment reliability and supports quality control in various industries.

Calibration Record Form Sample PDF Viewer

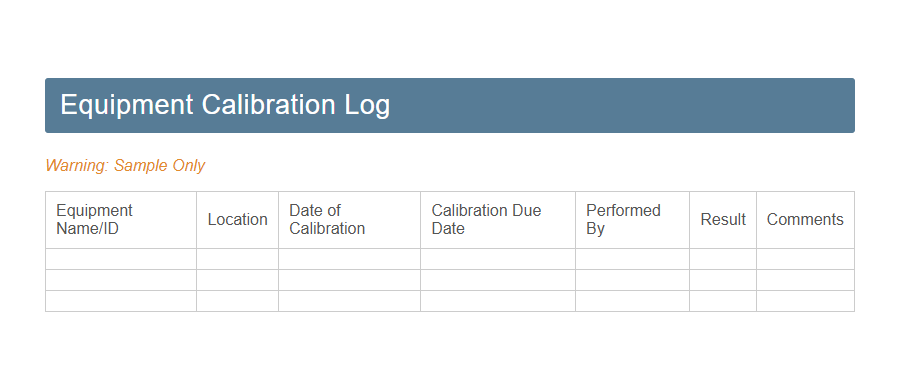

Image example of Calibration Record Form:

Calibration Record Form Samples

Equipment Calibration Log Template - PDF - HTML

Pressure Gauge Calibration Certificate - PDF - HTML

Temperature Sensor Calibration Record - PDF - HTML

Weighing Scale Calibration Sheet - PDF - HTML

pH Meter Calibration Log - PDF - HTML

Torque Wrench Calibration Form - PDF - HTML

Flow Meter Calibration Record - PDF - HTML

Pipette Calibration Certificate - PDF - HTML

Multimeter Calibration Report - PDF - HTML

Autoclave Calibration Log - PDF - HTML

Spectrophotometer Calibration Form - PDF - HTML

Gas Detector Calibration Record - PDF - HTML

Hardness Tester Calibration Sheet - PDF - HTML

Introduction to Calibration Record Forms

Calibration Record Forms are essential documents used to track the accuracy and performance of measurement instruments over time. These forms help ensure that equipment meets required standards and operates reliably within specified tolerances.

Maintaining accurate calibration records supports quality control and regulatory compliance in various industries.

Importance of Calibration Record Keeping

Why is maintaining a Calibration Record Form essential for quality control? Accurate calibration records ensure that all measuring instruments are functioning correctly and consistently. This practice helps prevent errors, guaranteeing reliable and precise measurements in all processes.

How does a Calibration Record Form support regulatory compliance? Proper documentation of calibration activities meets industry standards and audit requirements. It provides traceability and accountability, which are crucial for certifications and maintaining product quality.

Key Components of a Calibration Record Form

A Calibration Record Form is essential for documenting the calibration process of instruments and equipment. It ensures traceability and accuracy by capturing critical information during calibration.

- Instrument Identification - This includes the unique ID, model, and serial number of the equipment being calibrated.

- Calibration Dates - Records the date of calibration and the next scheduled calibration to maintain timely verification.

- Calibration Results - Contains the actual measurement data, measurement uncertainties, and pass/fail status to verify compliance with standards.

Regulatory Requirements for Calibration Documentation

Calibration Record Forms are essential documents that ensure the accuracy and reliability of measuring instruments in compliance with industry standards.

Regulatory requirements for calibration documentation mandate detailed records of calibration activities, including dates, methods, results, and personnel involved. These records serve as official proof of compliance with quality control standards and facilitate audits and traceability throughout the instrument's lifecycle.

Step-by-Step Guide to Completing a Calibration Record

A Calibration Record Form is essential for documenting the accuracy and performance of measurement instruments.

It provides a detailed account of calibration activities, ensuring compliance with quality standards and traceability.

Begin by entering the identification details of the instrument, such as serial number, model, and location.

Record the date and time of calibration along with the technician's name performing the procedure.

Next, document the reference standards or equipment used during the calibration process.

Include their identification numbers and certification status to maintain traceability.

Proceed by recording the initial measurements taken from the instrument before adjustment.

Note any deviations from the expected values and specify the acceptable tolerance limits.

If adjustments are necessary, detail the corrective actions applied to the instrument.

Follow this by capturing the final measurements after adjustments to confirm instrument accuracy.

Conclude by signing and dating the form to validate the calibration process.

Store the completed calibration record securely for future audits and quality control reviews.

Common Calibration Errors and How to Avoid Them

A Calibration Record Form is essential for tracking the accuracy and consistency of instruments over time. Common calibration errors include incorrect recording of data, failure to follow calibration procedures, and using unqualified equipment. Avoid these errors by ensuring thorough training, adhering strictly to standard protocols, and regularly reviewing the calibration records for accuracy.

Best Practices for Storing Calibration Records

Proper storage of calibration record forms ensures accuracy and traceability in equipment maintenance. Implementing best practices preserves the integrity and accessibility of calibration data for audits and quality control.

- Centralized Digital Storage - Store calibration records in a secure, centralized digital system to facilitate easy access and prevent data loss.

- Regular Backups - Perform routine backups of calibration data to safeguard information against accidental deletion or hardware failure.

- Controlled Access - Limit access to calibration records to authorized personnel only, ensuring data integrity and preventing unauthorized modifications.

Digital vs. Paper Calibration Record Forms

Calibration record forms are essential for tracking the accuracy and maintenance of measurement instruments. Digital calibration record forms offer easier data storage, faster retrieval, and enhanced accuracy compared to traditional paper forms. Paper forms, while simple and requiring no electronic devices, can be prone to errors, misplacement, and time-consuming manual entries.

Audit Preparation: Ensuring Calibration Record Compliance

Maintaining accurate Calibration Record Forms is essential for audit readiness and regulatory compliance. Proper documentation ensures traceability and supports consistent quality control throughout equipment usage.

- Clear Documentation - Ensures all calibration activities are recorded precisely for audit verification.

- Regular Updates - Keeps calibration records current to reflect any changes or maintenance performed on instruments.

- Compliance Alignment - Matches calibration forms with industry standards and organizational policies to meet audit requirements.

Thorough preparation of Calibration Record Forms strengthens audit outcomes and upholds operational integrity.