Calibration request and record forms streamline the process of ensuring equipment accuracy and compliance by documenting calibration requirements and results. These forms detail essential information such as equipment identification, calibration standards, and measurement outcomes. Clear examples of calibration request and record forms help organizations maintain quality control and traceability effectively.

Calibration Request and Record Form Sample PDF Viewer

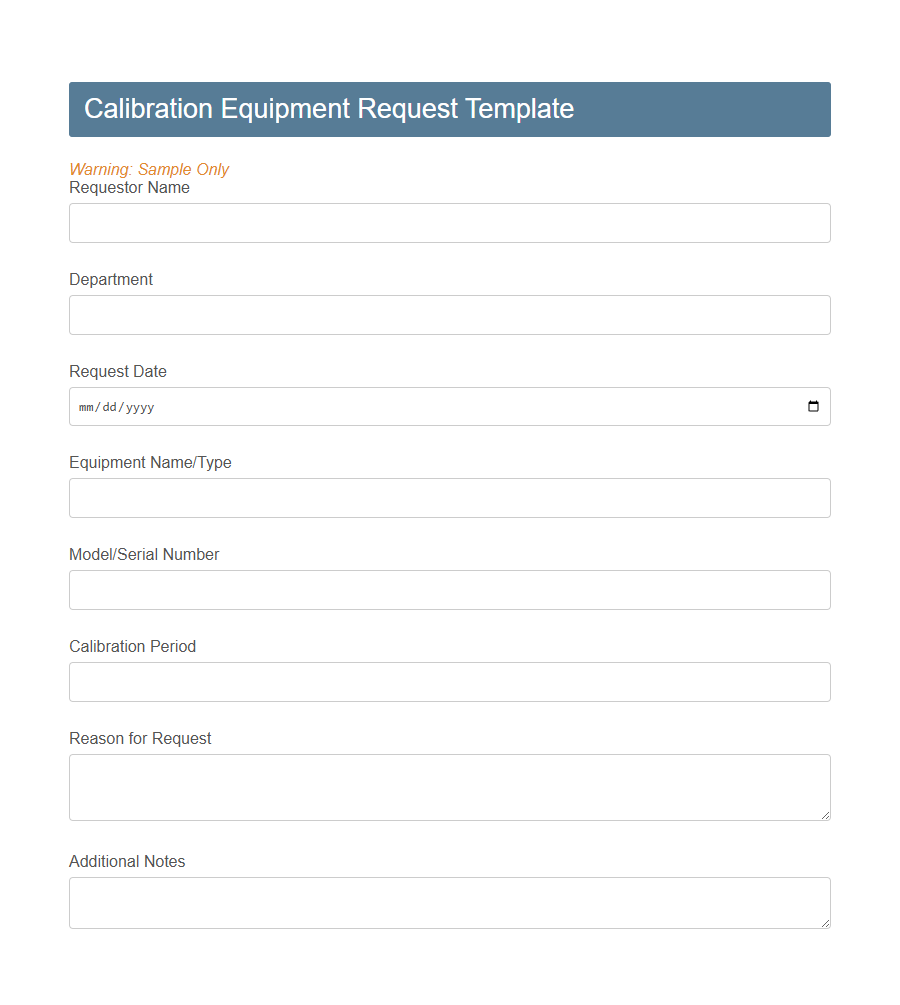

Image example of Calibration Request and Record Form:

Calibration Request and Record Form Samples

Calibration Equipment Request Template - PDF - HTML

Calibration Certificate Record Template - PDF - HTML

Internal Calibration Log Sheet - PDF - HTML

Calibration Due Reminder Form - PDF - HTML

Calibration Master List Template - PDF - HTML

Calibration Traceability Record - PDF - HTML

Calibration Nonconformance Report - PDF - HTML

Calibration Schedule Planning Sheet - PDF - HTML

Equipment Calibration Status Tag Template - PDF - HTML

On-Site Calibration Request Form - PDF - HTML

Instrument Calibration Verification Log - PDF - HTML

Vendor Calibration Service Request Template - PDF - HTML

Calibration Evidence Attachment Form - PDF - HTML

Introduction to Calibration Requests

Calibration requests are essential for ensuring the accuracy and reliability of measurement instruments. They initiate the formal process of verifying and adjusting equipment to meet predefined standards.

The Calibration Request and Record Form serves as the official document used to request calibration services. It captures critical information such as instrument details, calibration requirements, and requester identification to maintain traceability and quality control.

Importance of Calibration Records

Why are calibration records important for equipment management? Calibration records provide documented evidence that instruments are tested and maintained accurately, ensuring reliable measurements. These records help in identifying trends and preventing equipment failures, supporting quality control and compliance with industry standards.

Key Components of a Calibration Request Form

A Calibration Request and Record Form is essential for documenting the calibration process of measurement instruments. It ensures accuracy and traceability throughout the equipment's lifecycle.

- Instrument Identification - This section records the specific details of the instrument, including model, serial number, and manufacturer.

- Calibration Details - It captures the date of calibration, standards used, and environmental conditions during the process.

- Results and Certification - This part documents the calibration outcomes, any adjustments made, and includes the technician's signature for validation.

Steps for Submitting a Calibration Request

Submitting a Calibration Request requires completing a specific form to ensure all necessary information is captured accurately.

First, identify the equipment needing calibration and gather its relevant details such as model number and serial number. Next, fill out the Calibration Request and Record Form with accurate data to avoid delays in processing.

Essential Fields in a Calibration Record Form

The Calibration Request and Record Form ensures accurate tracking and documentation of instrument calibration activities. Essential fields in this form capture critical information to maintain consistency and compliance.

- Equipment Identification - This field records unique identifiers such as serial numbers or asset tags to ensure traceability of the calibrated item.

- Calibration Date - It specifies the exact date when calibration is performed, helping to schedule future calibrations and monitor intervals.

- Calibration Results - This section documents the outcome of the calibration, including measurements, tolerances, and pass/fail status for quality assurance.

Best Practices for Accurate Calibration Documentation

Accurate calibration documentation is essential for maintaining equipment reliability and ensuring compliance with industry standards. Properly completed Calibration Request and Record Forms support traceability and quality assurance in calibration processes.

- Complete all required fields - Ensuring every section of the form is filled out prevents missing information that could lead to calibration errors or delays.

- Use consistent terminology - Applying standardized language improves clarity and facilitates better communication between technicians and auditors.

- Record calibration results precisely - Accurate entry of measurements and observations guarantees reliable documentation for future reference and audits.

Following these best practices enhances the integrity of the calibration process and supports ongoing operational excellence.

Common Errors in Calibration Requests

Calibration request forms often contain common errors such as incomplete information, including missing equipment identification or calibration standards. Incorrect or unclear specification of the required calibration parameters can lead to improper calibration results. Failure to include necessary approvals or signatures may also delay the calibration process and affect record-keeping accuracy.

Digital vs. Paper Calibration Forms

Calibration Request and Record Forms are essential tools for maintaining accuracy and traceability in equipment calibration processes. Digital forms offer enhanced accessibility, automatic data capture, and easier storage compared to traditional paper forms.

Digital calibration forms streamline workflows by reducing errors and enabling faster data retrieval without the physical limitations of paper.

Maintaining Compliance with Calibration Records

The Calibration Request and Record Form is essential for maintaining accurate and organized documentation of all calibration activities. Proper use of this form ensures compliance with industry standards and regulatory requirements by providing a clear audit trail. Consistently updated calibration records support equipment reliability and help avoid costly non-compliance issues.