A Quality Control Checklist Form ensures consistent product standards by systematically identifying defects and monitoring production processes. It helps teams document inspections, verify compliance with specifications, and improve overall quality. Using detailed examples of these forms enhances understanding and effective implementation.

Quality Control Checklist Form Sample PDF Viewer

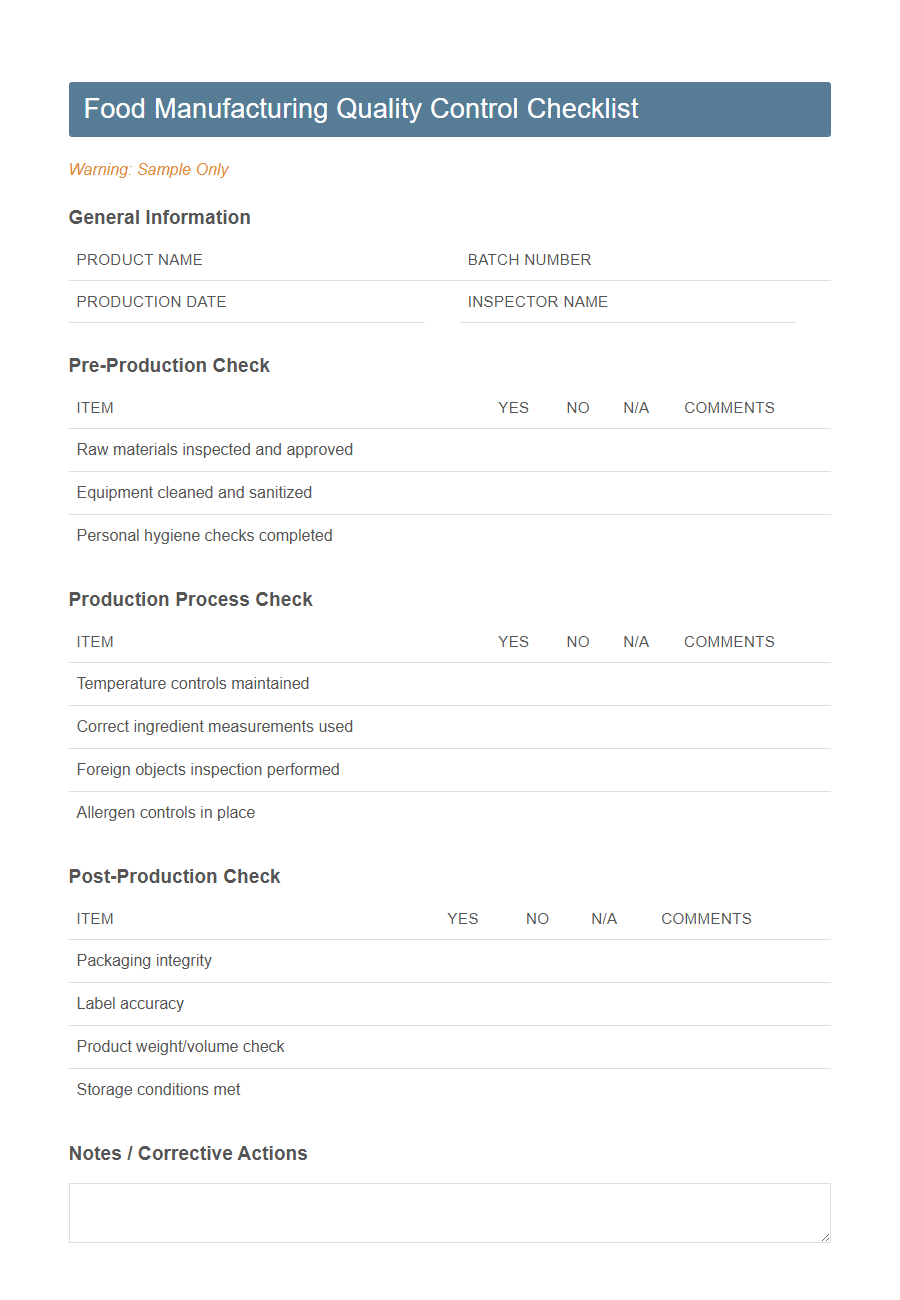

Image example of Quality Control Checklist Form:

Quality Control Checklist Form Samples

Food Manufacturing Quality Control Checklist - PDF - HTML

Construction Site Quality Control Inspection Form - PDF - HTML

Software Testing Quality Assurance Checklist - PDF - HTML

Pharmaceutical Production QC Audit Template - PDF - HTML

Garment Factory Quality Control Checklist - PDF - HTML

Medical Device Assembly QC Form - PDF - HTML

Restaurant Cleanliness & Food Safety QC Checklist - PDF - HTML

Laboratory Equipment Calibration QC Template - PDF - HTML

Electronics Assembly Line Quality Control Form - PDF - HTML

Hotel Room Housekeeping QC Inspection Checklist - PDF - HTML

Automotive Parts Manufacturing QC Checklist - PDF - HTML

Cosmetic Production Batch Quality Control Form - PDF - HTML

Warehouse Shipping and Receiving QC Checklist - PDF - HTML

Welding Procedure Quality Control Inspection Form - PDF - HTML

Introduction to Quality Control Checklist Forms

A Quality Control Checklist Form serves as a vital tool in ensuring products and services meet defined standards. It helps streamline inspection processes by providing a structured list of criteria to verify quality consistently. Using this form reduces errors, enhances efficiency, and supports continuous improvement in production or service delivery.

Importance of Quality Control in Various Industries

Why is a quality control checklist form essential across different industries? It ensures consistent product standards and helps identify defects early in the production process. This practice minimizes waste, reduces costs, and enhances customer satisfaction by delivering reliable results.

Key Components of an Effective Checklist Form

A Quality Control Checklist Form ensures that all critical aspects of a product or process meet defined standards before approval. It systematically identifies defects and areas for improvement to maintain consistency and reliability.

Key components include clear criteria, measurable standards, and spaces for observations and corrections.

Steps to Create a Quality Control Checklist

Creating a quality control checklist ensures consistent product standards and reduces errors.

Identify key quality criteria relevant to the product or process, then list specific checkpoints for evaluation. Organize these checkpoints in a logical sequence to facilitate thorough inspections and efficient workflow.

Use clear, concise language to describe each item on the checklist, making it easy for inspectors to understand and follow. Include sections for recording inspection results, observations, and corrective actions to track quality issues and improvements.

Test the checklist with a small team to verify its effectiveness and make necessary adjustments. Train all personnel involved in quality control on how to properly use the checklist to maintain uniform standards across all inspections.

Review and update the checklist regularly based on feedback and changing quality requirements. This practice helps sustain product quality and adapt to process improvements or regulatory changes.

Common Mistakes in Quality Control Checklists

Quality control checklist forms are essential tools for maintaining product standards, but certain common mistakes can undermine their effectiveness. Recognizing these errors helps improve quality assurance processes and ensures consistent outcomes.

- Inadequate Detail - Checklists that lack specific criteria can lead to inconsistent evaluations and overlooked defects.

- Overcomplication - Excessively detailed checklists may overwhelm users, reducing accuracy and efficiency.

- Failure to Update - Using outdated checklists can result in missed quality issues due to evolving standards or processes.

Addressing these pitfalls enhances the reliability and usefulness of quality control checklist forms in production environments.

Best Practices for Using Checklist Forms

Quality Control Checklist Forms are essential tools for maintaining consistent standards and ensuring all procedures meet required specifications. Using these forms effectively leads to improved accuracy and enhanced product quality.

- Keep the checklist clear and concise - A straightforward checklist reduces confusion and ensures every step is followed precisely.

- Update the checklist regularly - Regular revisions reflect changes in processes or standards, keeping the checklist relevant and effective.

- Train personnel on checklist use - Proper training ensures that team members understand the checklist's purpose and use it consistently.

Integration of Digital Tools in Quality Control

The integration of digital tools in quality control checklists enhances accuracy and streamlines inspection processes. Leveraging technology ensures real-time data capture and more efficient issue tracking during quality assessments.

- Digital Data Entry - Enables immediate and error-free input of inspection results through tablets or mobile devices.

- Automated Reporting - Generates instant reports that help identify trends and reduce manual documentation efforts.

- Real-Time Monitoring - Allows supervisors to track quality metrics and compliance remotely for faster decision-making.

Benefits of a Standardized Quality Control Checklist

A standardized Quality Control Checklist ensures consistent evaluation criteria across all projects, reducing errors and improving product reliability. It streamlines communication among team members by providing a clear, uniform framework for quality assessment. This consistency enhances customer satisfaction by delivering products that consistently meet established standards.

Quality Control Checklist Templates and Examples

A Quality Control Checklist Form is essential for ensuring product and service standards are consistently met.

Quality Control Checklist Templates provide a structured format to streamline inspections and verify compliance. Examples of these templates demonstrate how to customize items based on industry-specific requirements, improving accuracy and efficiency in the quality assurance process.