A Tool Changeover Request Form streamlines the process of switching equipment in manufacturing or production settings. This form ensures clear communication and efficient scheduling to minimize downtime and errors. Examples of completed forms demonstrate how to accurately capture essential details for a smooth tool transition.

Tool Changeover Request Form Sample PDF Viewer

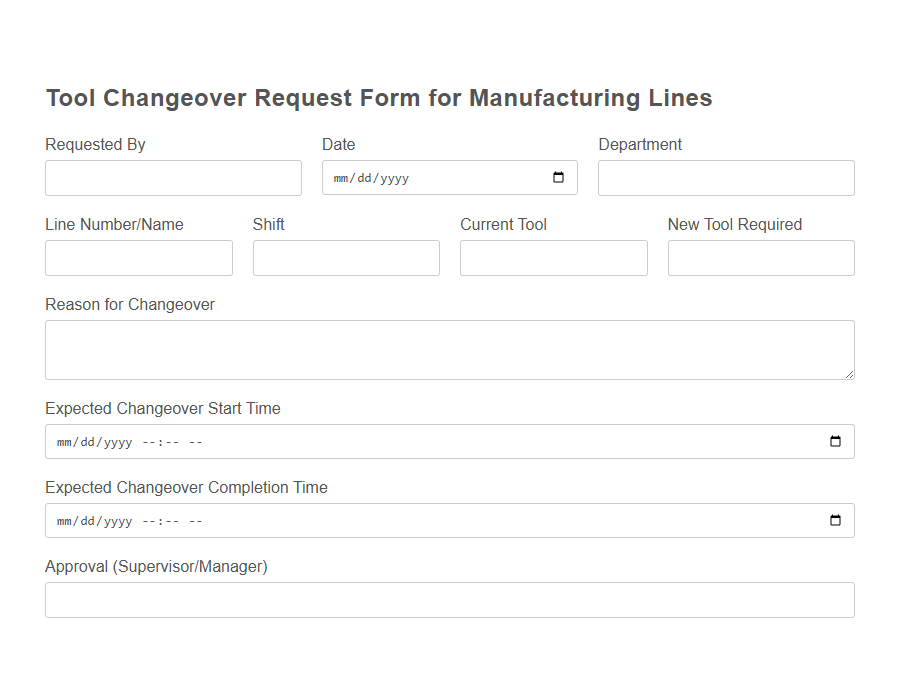

Image example of Tool Changeover Request Form:

Tool Changeover Request Form Samples

Tool Changeover Request Form for Manufacturing Lines - PDF - HTML

Tool Changeover Request Form for Injection Molding Machines - PDF - HTML

Tool Changeover Request Form for CNC Machining Centers - PDF - HTML

Tool Changeover Request Form for Pharmaceutical Packaging - PDF - HTML

Tool Changeover Request Form for Food Processing Equipment - PDF - HTML

Tool Changeover Request Form for Printing Presses - PDF - HTML

Tool Changeover Request Form for Automotive Assembly - PDF - HTML

Tool Changeover Request Form for Electronics SMT Lines - PDF - HTML

Tool Changeover Request Form for Die Casting Machines - PDF - HTML

Tool Changeover Request Form for Textile Weaving Looms - PDF - HTML

Tool Changeover Request Form for Metal Stamping Press - PDF - HTML

Tool Changeover Request Form for Plastic Extrusion Lines - PDF - HTML

Tool Changeover Request Form for Aerosol Filling Machines - PDF - HTML

Tool Changeover Request Form for Beverage Bottling Lines - PDF - HTML

Tool Changeover Request Form for Blister Packaging Machines - PDF - HTML

Introduction to Tool Changeover Request Forms

Tool Changeover Request Forms are essential documents used in manufacturing to ensure efficient and accurate tool replacement processes. These forms help streamline communication and reduce downtime during production changes.

- Standardization - The form provides a consistent method for requesting and documenting tool changeovers.

- Accountability - It assigns responsibility to personnel involved in the tool change process to avoid errors.

- Efficiency - Using the form minimizes delays by clearly outlining the requirements and timing for tool changes.

Implementing Tool Changeover Request Forms improves production flow and supports quality control in manufacturing operations.

Importance of Efficient Tool Changeovers

Efficient tool changeovers are critical to minimizing downtime and maintaining production flow.

Prompt and accurate completion of a Tool Changeover Request Form ensures that necessary tools are available and properly configured, reducing delays. Streamlined tool changeovers improve overall equipment effectiveness and boost manufacturing productivity.

Key Components of a Tool Changeover Request Form

A Tool Changeover Request Form is essential for managing and documenting the process of switching tools in manufacturing or production settings. It ensures that all necessary information is clearly communicated to facilitate a smooth and efficient tool change.

Key components include details such as the tool identification, reason for changeover, requested date and time, and the requesting department or personnel.

When to Submit a Tool Changeover Request

Submit a Tool Changeover Request as soon as a new production run requires different tooling. Timely requests ensure minimal downtime and efficient workflow.

- Before Scheduled Production Changes - Submit the request prior to starting a new batch that demands different tools.

- When Tooling Wear is Detected - Request a changeover if tools show signs of wear affecting product quality.

- After Process Adjustments - File a request following any modifications in production specifications requiring new tools.

Step-by-Step Guide to Filling Out the Form

What is the first step in filling out the Tool Changeover Request Form? Begin by entering the date and time of the requested tool change. This information helps schedule the changeover accurately.

How do you specify the tools involved in the changeover? List the current tool being replaced and the new tool to be installed. Clear identification prevents errors during the changeover process.

Where should you indicate the reason for the tool change? Provide a brief explanation in the designated section of the form. This ensures the changeover is justified and documented.

What details are needed about the equipment or machine? Record the machine's identification number and location. Accurate details help the maintenance team locate and service the correct equipment.

How do you communicate the urgency of the tool change? Select the priority level from the available options. This guides the maintenance team on how quickly to respond.

What information should be given about the personnel involved? Include the names and contact details of the requester and the operator. Clear communication supports coordination during the changeover.

Why is it important to specify any special instructions or safety precautions? Write down any necessary instructions or safety notes. This helps ensure a smooth and safe tool changeover process.

How do you confirm the completion of the tool changeover? Fill in the section for the maintenance technician's name and the completion date. This serves as proof that the changeover was successfully performed.

What should be done if there are any issues during the changeover? Note any problems encountered in the comments area. Documenting issues facilitates follow-up and continuous improvement.

How do you finalize the Tool Changeover Request Form? Review all entered data for accuracy before submitting it. Accurate and complete forms enhance operational efficiency and safety.

Roles and Responsibilities in the Changeover Process

The Tool Changeover Request Form streamlines the transition between different tools in a manufacturing process.

The production team is responsible for identifying the need for a tool change and submitting the request form accurately. Maintenance personnel review the request, prepare the necessary tools, and execute the changeover to minimize downtime.

Benefits of Using Standardized Request Forms

Using standardized Tool Changeover Request Forms ensures clear and consistent communication across teams, reducing errors and misunderstandings. It streamlines the approval process, saving time and improving overall efficiency in manufacturing operations. Standardized forms also provide a reliable record for tracking changeovers, aiding in quality control and future audits.

Common Challenges and Solutions in Tool Changeover Requests

Tool Changeover Request Forms are essential for streamlining the transition between different tools in manufacturing processes. Common challenges often arise from miscommunication and incomplete information, affecting efficiency and accuracy.

- Incomplete Information - Missing details on the form can cause delays and errors during the changeover process.

- Poor Communication - Lack of clarity between operators and maintenance teams leads to misunderstandings and slowdown.

- Inconsistent Documentation - Variability in form formats creates confusion and complicates record-keeping.

Digital vs. Paper Tool Changeover Request Forms

Digital Tool Changeover Request Forms streamline the process by enabling instant submission and real-time tracking, reducing errors and delays. Paper forms often lead to misplaced documents, slower communication, and difficulty in maintaining accurate records. Switching to digital forms enhances efficiency, improves data accuracy, and supports better decision-making in tool management.