A Scrap Material Report Form is essential for tracking and managing waste generated during production processes. This report helps businesses monitor scrap quantities, identify recurring issues, and implement cost-saving measures. Accurate documentation supports improved inventory control and enhances overall operational efficiency.

Scrap Material Report Form Sample PDF Viewer

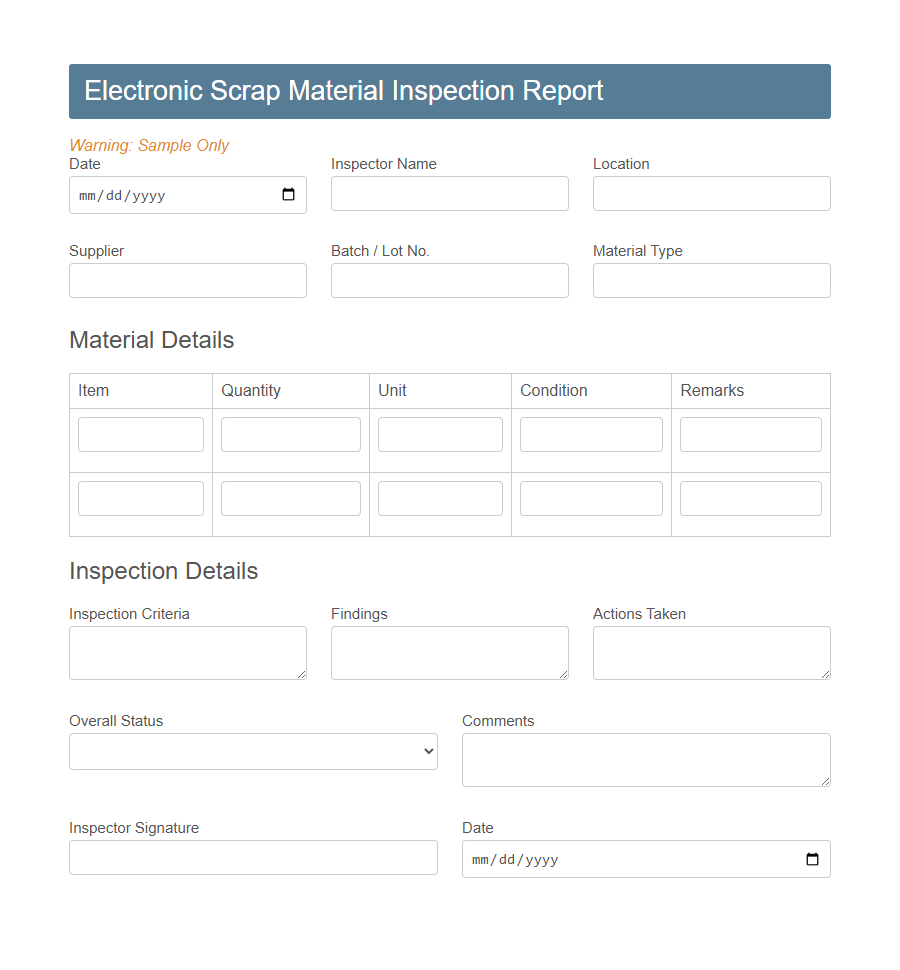

Image example of Scrap Material Report Form:

Scrap Material Report Form Samples

Electronic Scrap Material Inspection Report Template - PDF - HTML

Construction Site Scrap Material Log Sheet - PDF - HTML

Textile Industry Scrap Material Tracking Form - PDF - HTML

Food Processing Scrap Material Disposal Report - PDF - HTML

Automotive Scrap Material Collection Report Template - PDF - HTML

Pharmaceutical Scrap Material Control Sheet - PDF - HTML

Plastic Manufacturing Scrap Material Audit Form - PDF - HTML

Metal Workshop Scrap Material Summary Report - PDF - HTML

Furniture Manufacturing Scrap Material Declaration Form - PDF - HTML

Printing Press Scrap Paper Material Report - PDF - HTML

Glass Factory Scrap Material Reconciliation Template - PDF - HTML

Chemical Plant Scrap Material Removal Record - PDF - HTML

Recycling Center Scrap Material Intake Form - PDF - HTML

Introduction to the Scrap Material Report Form

The Scrap Material Report Form is a vital document used to track and manage leftover or waste materials in manufacturing and production processes. It helps organizations maintain accurate records of scrap quantities, types, and causes, ensuring efficient resource management. This form supports cost control and sustainability efforts by identifying areas for material optimization and waste reduction.

Purpose and Importance of Scrap Reporting

The Scrap Material Report Form is used to document and track materials that are discarded during manufacturing or production processes.

This form helps identify the quantity and type of scrap generated, enabling better management of resources and reduction of waste. Accurate scrap reporting supports cost control, improves operational efficiency, and promotes sustainable practices within the organization.

Key Sections of the Report Form

The Scrap Material Report Form is essential for documenting discarded materials during production. It ensures accurate tracking and accountability of scrap generated on-site.

- Identification Details - Captures information such as date, department, and personnel responsible for scrap generation.

- Material Description - Specifies the type, quantity, and condition of the scrap material documented.

- Reason for Scrap - Records the cause or defect that led to the material being classified as scrap.

Data Required for Accurate Reporting

Accurate data collection is essential for an effective Scrap Material Report Form. Proper documentation ensures clear tracking and accountability of scrap materials.

- Material Identification - Precise details about the type and grade of scrap material must be recorded for proper categorization.

- Quantity Measurement - Exact weight or volume of the scrap material is needed to assess loss and manage inventory.

- Date and Location - Recording the date and place of scrap generation helps in identifying process inefficiencies and tracing sources.

Thorough and accurate data entry improves the integrity and usefulness of scrap material reports.

Step-by-Step Guide to Completing the Form

What is the first step in completing a Scrap Material Report Form? Begin by accurately entering the date and identification details of the scrap material. This ensures proper tracking and accountability throughout the reporting process.

How do you describe the scrap material on the form? Provide a clear and precise description including type, quantity, and source of the scrap. Detailed information helps in assessing the value and disposition of the material.

What should be recorded regarding the condition of the scrap material? Note the physical state or any damage to the material thoroughly. This assists in evaluating potential reuse or recycling options.

Where do you list the reasons for the scrap generation? Include specific causes such as production defects or expired inventory. Understanding reasons supports better waste reduction strategies.

How do you assign responsibility on the Scrap Material Report Form? Identify the person or department responsible for generating the scrap. Accountability promotes better management and prevents future waste.

What information is needed about disposal or recycling? Specify the method of scrap disposition, whether recycled, sold, or discarded. Proper documentation ensures compliance with environmental regulations.

How should you review the form before submission? Double-check all entries for accuracy and completeness. Correct information avoids processing delays and errors in reporting.

Who needs to sign the Scrap Material Report Form? Obtain signatures from the responsible personnel and supervisors. Authorization confirms validation and approval of the scrap report.

Common Mistakes to Avoid in Scrap Documentation

The Scrap Material Report Form is essential for tracking and managing waste efficiently.

Common mistakes include inaccurate item descriptions and missing quantity details, which lead to confusion and improper inventory records. Failing to record the date and responsible personnel can cause accountability issues and hinder effective auditing.

Digital vs Paper-Based Scrap Material Reporting

Digital scrap material reporting offers increased efficiency and accuracy compared to traditional paper-based methods. Switching to digital reporting streamlines data management and enhances real-time tracking.

- Digital Reporting Saves Time - Automated data entry and instant submissions reduce manual workload and speed up the reporting process.

- Paper-Based Reporting Risks Errors - Handwritten forms can lead to data inaccuracies and lost information during handling or filing.

- Digital Systems Improve Accessibility - Reports stored electronically allow easy retrieval and analysis across multiple departments or locations.

Benefits of Using a Standardized Report Form

Using a standardized Scrap Material Report Form improves accuracy by ensuring consistent data collection across all departments. It simplifies tracking and analysis, making it easier to identify trends and address issues promptly.

This structured approach enhances communication and helps maintain compliance with regulatory requirements.

Tips for Improving Scrap Material Tracking

Maintaining accurate and detailed entries in the Scrap Material Report Form helps identify trends and reduce waste effectively. Regularly updating the form ensures real-time tracking and immediate corrective actions. Training staff on proper documentation techniques enhances consistency and accountability in scrap management.