A Daily Production Report Form tracks key metrics such as output quantity, machine performance, and labor efficiency to ensure smooth manufacturing operations. This report helps identify bottlenecks, monitor progress, and maintain quality standards by providing accurate, real-time data. Implementing effective examples of daily production report forms enhances decision-making and boosts overall productivity in the production process.

Daily Production Report Form Sample PDF Viewer

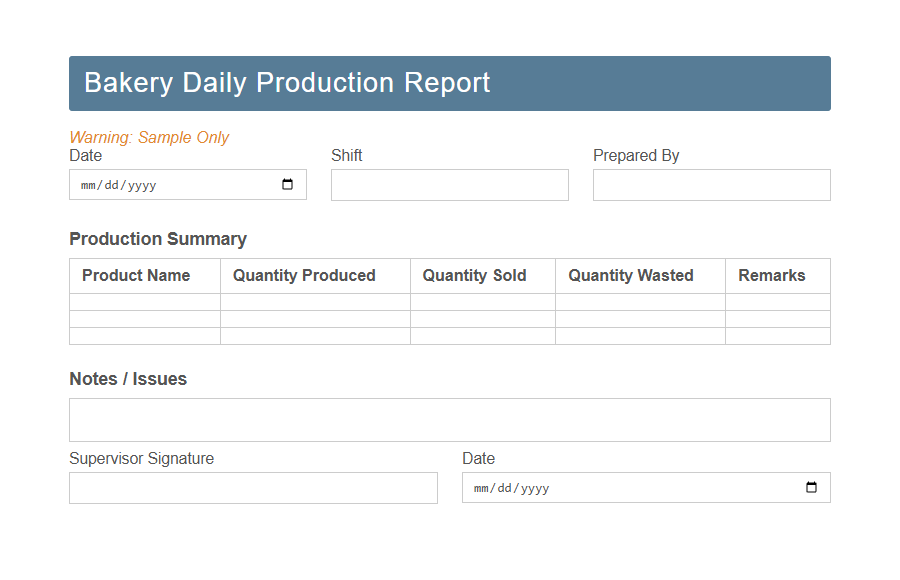

Image example of Daily Production Report Form:

Daily Production Report Form Samples

Bakery Daily Production Report Template - PDF - HTML

Garment Factory Daily Production Report Form - PDF - HTML

Food Processing Daily Production Log Sheet - PDF - HTML

CNC Machining Daily Output Report Template - PDF - HTML

Pharmaceutical Batch Production Daily Report - PDF - HTML

Printing Press Daily Job Production Form - PDF - HTML

Dairy Plant Daily Production Summary Template - PDF - HTML

Chemical Manufacturing Daily Production Record - PDF - HTML

Beverage Bottling Line Daily Report Template - PDF - HTML

Electronics Assembly Line Daily Output Sheet - PDF - HTML

Soap and Detergent Plant Daily Production Form - PDF - HTML

Meat Processing Facility Daily Report Template - PDF - HTML

Plastic Injection Molding Daily Production Log - PDF - HTML

Introduction to Daily Production Report Forms

A Daily Production Report Form is a crucial document used in manufacturing and construction to track daily work progress and productivity.

This form records important details such as the number of units produced, hours worked, and any issues encountered during the production process.

Importance of Daily Production Reporting

Daily Production Reports are essential for tracking progress and identifying issues promptly. They provide accurate data that supports decision-making and improves operational efficiency.

- Enhances Transparency - Daily reporting offers clear insights into production activities, allowing teams to monitor performance closely.

- Facilitates Problem Identification - Early detection of production delays or errors helps to implement corrective actions swiftly.

- Supports Data-Driven Decisions - Consistent documentation of production metrics enables better planning and resource allocation.

Key Components of a Daily Production Report

What are the key components of a Daily Production Report? A Daily Production Report typically includes essential information such as the production date, shift details, and total output. It also records machine performance, labor hours, and any production issues encountered during the shift.

Step-by-Step Guide to Filling Out the Form

The Daily Production Report Form captures essential data about daily manufacturing activities to ensure efficient tracking and management. Accurate completion of this form supports operational transparency and performance analysis.

- Gather Relevant Data - Collect all necessary production information including quantities, times, and any incidents before starting the form.

- Complete Header Information - Fill in the date, shift, department, and supervisor details to contextualize the report.

- Record Production Metrics - Enter the actual production output, machine performance, and downtime accurately in the designated fields.

- Note Quality Issues - Document any defects or deviations encountered during production to help improve processes.

- Review and Submit - Verify all information for accuracy and completeness before submitting the report to the relevant department.

Following these steps ensures the Daily Production Report Form is filled out clearly and effectively for reliable production tracking.

Common Mistakes in Production Reporting

Common mistakes in daily production report forms include inaccurate data entry, such as misstating quantities or times. Overlooking details like equipment downtime or material usage can lead to incomplete reports. Failure to update the report promptly results in outdated information that hinders decision-making.

Benefits of Using Standardized Report Forms

Using standardized Daily Production Report Forms ensures consistency in data collection, making it easier to compare performance across different shifts and projects. This uniformity reduces errors and streamlines communication between departments.

Standardized forms enhance decision-making by providing accurate and reliable production data in a clear format.

Digital vs. Paper-Based Production Reports

Daily production report forms are essential tools for tracking manufacturing progress and efficiency. Choosing between digital and paper-based reports can significantly impact data accuracy and accessibility.

- Digital reports offer real-time data entry - This enables instant updates and quicker decision-making on the production floor.

- Paper-based reports are prone to errors and delays - Manual entry increases the risk of data loss and miscommunication.

- Digital forms improve data storage and analysis - They facilitate easier retrieval and comprehensive reporting over time.

Best Practices for Accurate Data Entry

Accurate data entry in a Daily Production Report Form requires clear and consistent documentation of all production activities and outputs. Using standardized codes and labels helps minimize errors and ensures uniformity across reports. Regular training and review of data entry procedures support reliable and timely reporting for effective production management.

Enhancing Productivity with Effective Reporting

A Daily Production Report Form is essential for tracking progress and identifying bottlenecks in manufacturing processes.

Using an effective Daily Production Report Form enhances productivity by providing real-time data that helps managers make informed decisions. This report facilitates clear communication between teams, ensuring issues are addressed promptly and resources are allocated efficiently.