A Non-Conformance Report (NCR) form documents deviations from project specifications or quality standards, helping organizations identify and address issues promptly. Examples of NCR forms include design discrepancies, material defects, process errors, and safety violations. These examples guide teams in effectively reporting and managing non-conformance to maintain compliance and improve operational quality.

Non-Conformance Report Form (NCR) Sample PDF Viewer

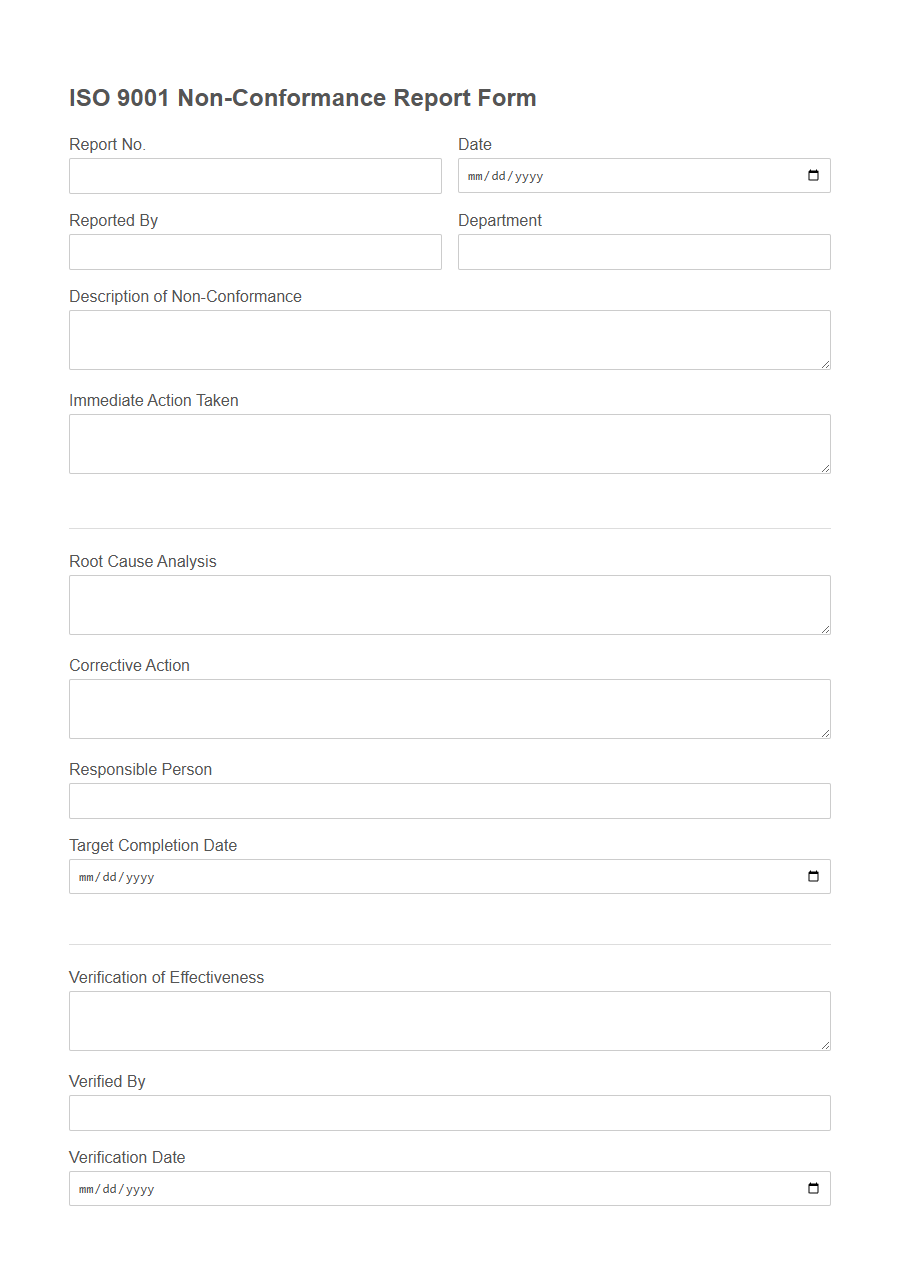

Image example of Non-Conformance Report Form (NCR):

Non-Conformance Report Form (NCR) Samples

ISO 9001 Non-Conformance Report Form - PDF - HTML

Supplier Quality Non-Conformance Record Template - PDF - HTML

Construction Site NCR Template - PDF - HTML

Manufacturing Process Non-Conformance Report - PDF - HTML

Food Safety NCR Form (HACCP-Compliant) - PDF - HTML

Medical Device Non-Conformance Report Template - PDF - HTML

Pharmaceutical GMP Non-Conformance Report - PDF - HTML

Welding Inspection NCR Form - PDF - HTML

Aerospace AS9100 Non-Conformance Report - PDF - HTML

Environmental Incident Non-Conformance Report - PDF - HTML

IT Service Management Non-Conformance Record - PDF - HTML

Laboratory Audit NCR Template - PDF - HTML

Automotive IATF 16949 Non-Conformance Report - PDF - HTML

Civil Engineering Project NCR Form - PDF - HTML

Oil & Gas Safety Non-Conformance Report Template - PDF - HTML

Introduction to Non-Conformance Report Forms (NCR)

Non-Conformance Report Forms (NCR) are crucial documents used to identify and address deviations from specified standards in products or processes. They help organizations maintain quality control and ensure compliance with regulations.

- Purpose - NCR forms document non-conforming materials or processes to track and resolve issues efficiently.

- Identification - The form captures detailed information about the nature and cause of the non-conformance for analysis.

- Corrective Actions - NCRs facilitate the implementation of corrective measures to prevent recurrence of non-conformities.

Implementing NCR forms supports continuous improvement and strengthens overall quality management systems.

Importance of NCRs in Quality Management

Non-Conformance Report Forms (NCRs) play a crucial role in identifying and documenting deviations from quality standards. Their use ensures that corrective actions are systematically implemented to prevent recurrence.

- Enhances Quality Control - NCRs provide a structured method for detecting and addressing non-conformities in processes and products.

- Facilitates Continuous Improvement - The detailed documentation in NCRs allows organizations to analyze trends and implement improvements.

- Supports Compliance and Accountability - NCRs help maintain regulatory compliance and hold teams accountable for quality standards.

Key Components of a Non-Conformance Report Form

A Non-Conformance Report Form (NCR) is essential for documenting deviations from specified standards or requirements in a project or process. Key components include a detailed description of the non-conformance, identification of the responsible parties, and the impact or risk associated with the issue. The form also captures corrective actions, verification of their effectiveness, and signatures for accountability and approval.

Steps in Completing an NCR Form

The first step in completing a Non-Conformance Report Form (NCR) involves clearly identifying and describing the non-conformance issue, including details such as the date, location, and parties involved. The next step requires documenting the immediate actions taken to contain or address the non-conformance and assigning responsibility for further investigation. Finally, the form must include a thorough analysis of the root cause, corrective actions to prevent recurrence, and verification measures to ensure the effectiveness of these actions.

Common Causes for Non-Conformance

A Non-Conformance Report Form (NCR) is used to document deviations from specified standards in a project or process.

It helps identify and address issues to prevent recurrence and improve quality management.

Common causes for non-conformance include human error, such as incorrect measurements or failure to follow procedures.

Material defects and equipment malfunctions frequently contribute to non-conformance by disrupting production quality.

Poor communication and inadequate training often lead to non-conformance by creating misunderstandings or improper execution.

Environmental factors, like temperature or humidity variations, can also affect product compliance with standards.

Inconsistent processes or lack of standardized procedures are key reasons why non-conformance occurs.

These inconsistencies result in variable outputs that do not meet quality specifications.

Roles and Responsibilities in NCR Management

What are the key roles involved in Non-Conformance Report (NCR) management? The NCR process typically includes roles such as the initiator, who identifies the non-conformance, the quality manager who reviews the report, and the corrective action team responsible for addressing the issues.

Who is responsible for ensuring the accuracy of information in an NCR? The initiator must provide detailed and precise information about the non-conformance, while the quality assurance team verifies the data for completeness and validity before proceeding.

What role does management play in NCR management? Management is accountable for approving corrective actions and providing necessary resources to resolve the non-conformance effectively and prevent recurrence.

How are corrective actions assigned and tracked in NCR management? The corrective action team is responsible for developing and implementing solutions, with the quality control department monitoring progress until full resolution is confirmed.

Who ensures communication of NCR status and outcomes to relevant parties? The quality manager coordinates communication across departments, ensuring stakeholders are informed about the status, findings, and corrective measures of the NCR.

NCR Review and Approval Process

The Non-Conformance Report Form (NCR) review and approval process ensures identified issues are thoroughly evaluated and appropriately addressed. This process involves systematic validation and authorization to maintain quality standards and compliance.

- Initial Review - The NCR is first examined to verify the accuracy and completeness of the documented non-conformance details.

- Investigation - A detailed analysis is conducted to determine the root cause and potential impact of the non-conformance.

- Approval and Closure - Authorized personnel review the corrective actions and formally approve the resolution before closing the NCR.

Corrective and Preventive Actions Linked to NCRs

A Non-Conformance Report (NCR) form documents deviations from standard procedures or specifications in a project or process.

Corrective and preventive actions linked to NCRs ensure that identified issues are addressed and recurrence is prevented. These actions involve analyzing root causes, implementing fixes, and monitoring effectiveness to improve overall quality and compliance.

Benefits of Using NCR Forms in Organizations

Non-Conformance Report (NCR) forms play a crucial role in identifying and documenting deviations from established standards or procedures within an organization. They enable systematic tracking and analysis of issues, facilitating prompt corrective actions that improve overall quality and compliance.

Using NCR forms enhances organizational accountability by ensuring that problems are recorded and addressed efficiently, reducing the risk of recurring errors and costly rework.