Engineering Change Order (ECO) forms document modifications to product designs or manufacturing processes, ensuring all changes are tracked and approved systematically. These forms include essential details such as description of the change, reasons, impacted parts, and authorization signatures to maintain product quality and compliance. Examples of ECO forms vary by industry but share the common goal of streamlining change management and minimizing disruption.

Engineering Change Order (ECO) Form Sample PDF Viewer

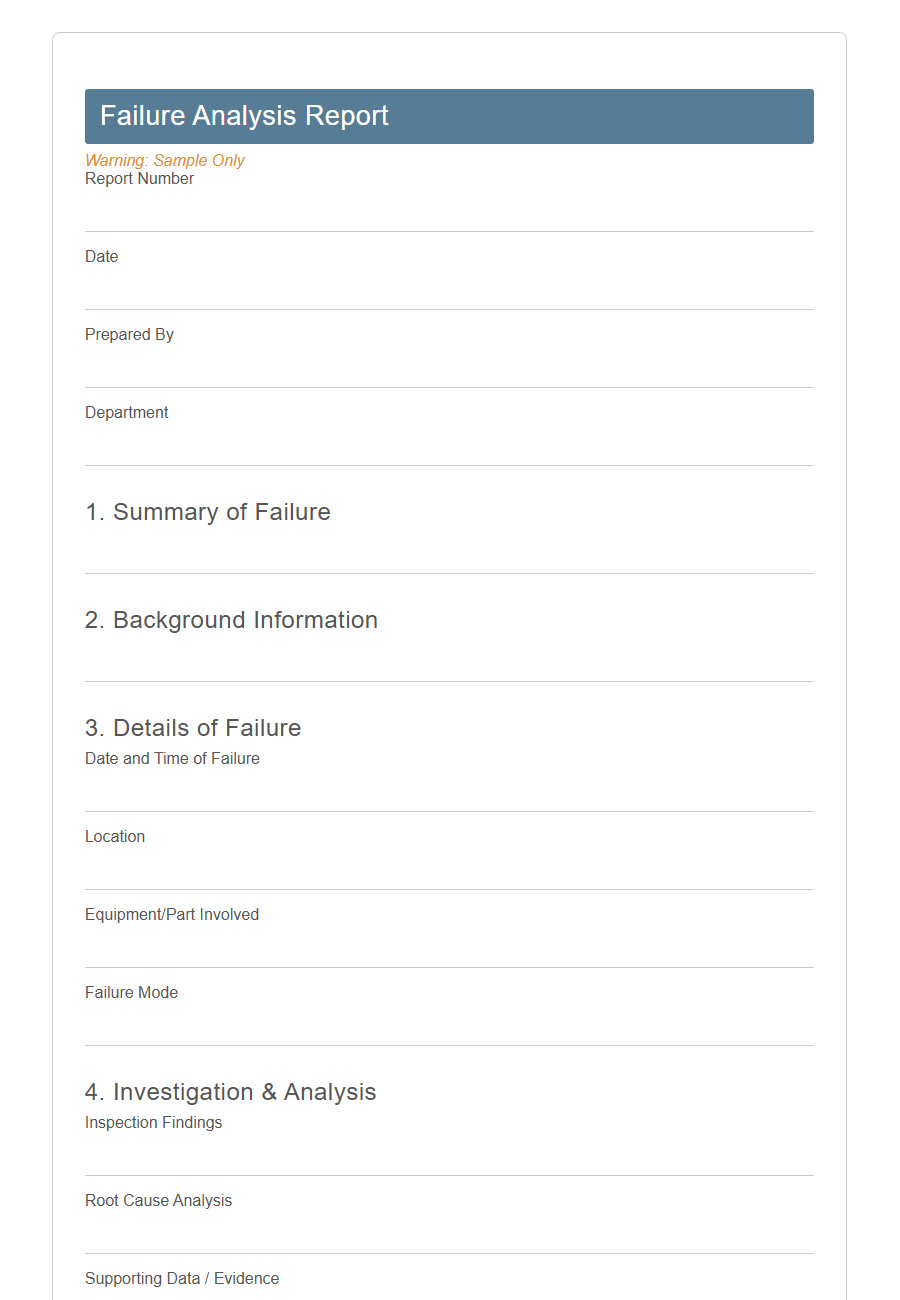

Image example of Engineering Change Order (ECO) Form:

Engineering Change Order (ECO) Form Samples

Failure Analysis Report Template - PDF - HTML

Prototype Evaluation Checklist - PDF - HTML

Product Lifecycle Management (PLM) Change Request Form - PDF - HTML

Software Bug Fix Documentation Template - PDF - HTML

Component Obsolescence Notification Form - PDF - HTML

PCB Layout Revision Record Sheet - PDF - HTML

Firmware Release Note Template - PDF - HTML

Validation Test Case Approval Form - PDF - HTML

Assembly Line Process Modification Request - PDF - HTML

Mechanical Drawing Revision Log - PDF - HTML

Supplier Deviation Request (SDR) Template - PDF - HTML

Nonconformance Material Report (NMR) - PDF - HTML

Technical Data Sheet (TDS) Update Form - PDF - HTML

Design Verification Plan and Report (DVP&R) - PDF - HTML

Configuration Management Change Impact Assessment - PDF - HTML

Introduction to Engineering Change Order (ECO)

What is an Engineering Change Order (ECO)? An Engineering Change Order (ECO) is a formal document used to propose, approve, and implement modifications to a product's design or manufacturing process. It ensures that all changes are tracked, communicated, and controlled to maintain product quality and consistency.

Importance of ECO Forms in Engineering Projects

Engineering Change Order (ECO) forms are crucial for documenting modifications in engineering projects, ensuring all changes are tracked systematically. These forms help maintain project integrity by providing clear communication among teams and preventing costly errors. Proper use of ECO forms enhances project efficiency and supports compliance with industry standards.

Key Components of an ECO Form

An Engineering Change Order (ECO) form is a critical document used to propose and track modifications to a product or system design. It ensures that all changes are documented, reviewed, and approved before implementation to maintain quality and consistency.

Key components of an ECO form include a detailed description of the change, reasons for the change, affected parts or systems, and the implementation plan. It also contains approval signatures from relevant departments, a change identification number, and the date of the change. These elements help streamline communication and prevent errors during the change management process.

Common Triggers for Engineering Change Orders

An Engineering Change Order (ECO) form is used to document and authorize modifications to a product's design or manufacturing process.

It ensures that changes are communicated clearly across all departments to maintain quality and consistency.

Common triggers for Engineering Change Orders include design errors detected during product development or testing.

These errors require formal updates to prevent defects and ensure the final product meets specifications.

Another common trigger is customer feedback indicating the need for improvements or corrections.

Incorporating these changes helps enhance product performance and customer satisfaction.

Manufacturing process changes, such as tooling updates or material substitutions, often initiate an ECO.

This ensures that alterations do not negatively impact product quality or compliance.

Regulatory requirements and industry standards updates can also trigger Engineering Change Orders.

Adhering to new regulations is critical for legal compliance and market access.

Step-by-Step ECO Form Submission Process

The Engineering Change Order (ECO) form is essential for documenting and managing design or process modifications systematically. Following a clear submission process ensures efficient approval and implementation of changes.

- Identify the Change - Clearly define the scope and reason for the engineering change to provide necessary context.

- Complete the ECO Form - Fill out all required fields accurately, including details of the modification and impacted components.

- Submit for Review - Send the completed ECO form to the engineering review board or relevant authority for evaluation and approval.

Best Practices for Filling Out ECO Forms

Filling out an Engineering Change Order (ECO) form accurately ensures clear communication and effective implementation of design modifications. Following best practices streamlines approval processes and minimizes errors.

- Provide Detailed Descriptions - Clearly describe the change, including the reason and impact on existing designs, to avoid ambiguity.

- Include All Relevant Documentation - Attach drawings, specifications, and test results that support the change for comprehensive review.

- Verify Approval Signatures - Ensure all required stakeholders review and sign the ECO form to validate the change authorization.

Roles and Responsibilities in ECO Management

The Engineering Change Order (ECO) form is essential for documenting proposed modifications to product designs, ensuring clarity and control throughout the change process.

- Initiator - Identifies the need for change and completes the initial ECO form with detailed descriptions.

- Engineering Team - Reviews technical feasibility and evaluates the impact of the proposed change on design and performance.

- Quality Assurance - Ensures that the change complies with quality standards and regulatory requirements before approval.

- Change Control Board (CCB) - Makes the final decision to approve, reject, or request further modifications to the ECO.

- Manufacturing and Supply Chain - Assesses effects on production processes and materials sourcing to implement approved changes effectively.

Clear assignment of roles and responsibilities in ECO management facilitates timely, accurate, and controlled engineering changes.

Digital vs. Paper ECO Forms: Pros and Cons

Engineering Change Order (ECO) forms streamline modifications in product design and manufacturing processes. Digital ECO forms enhance efficiency with real-time updates, easy tracking, and seamless collaboration across teams. Paper ECO forms offer simplicity and familiarity but often lead to slower processing, increased errors, and difficulties in document management.

Challenges in ECO Implementation and Solutions

Engineering Change Order (ECO) forms are essential documents used to manage and implement changes in product design and manufacturing processes.

Challenges in ECO implementation often include miscommunication between departments and delays in approval workflows, which can lead to costly production errors and project timeline setbacks.

Effective solutions involve establishing clear communication channels, utilizing digital ECO management systems, and standardizing approval procedures to enhance efficiency and accuracy.