Engineering calibration log form templates ensure precise documentation of equipment adjustments and performance standards. These forms streamline maintenance processes by providing consistent records crucial for quality control and regulatory compliance. Incorporating clear examples enhances understanding and facilitates accurate data entry for engineering teams.

Engineering Calibration Log Form Template Sample PDF Viewer

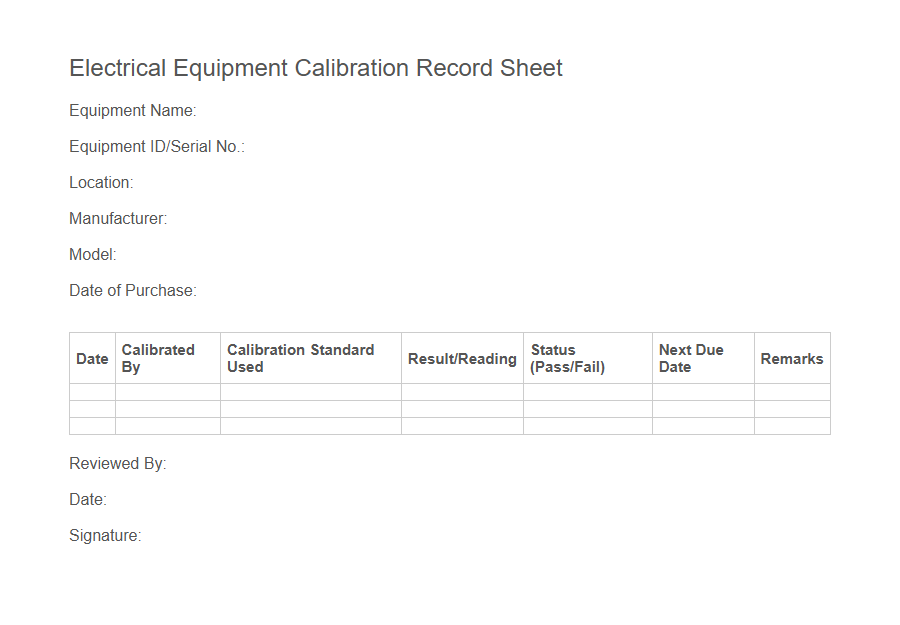

Image example of Engineering Calibration Log Form Template:

Engineering Calibration Log Form Template Samples

Electrical Equipment Calibration Record Sheet - PDF - HTML

Mechanical Tool Calibration Checklist Template - PDF - HTML

Laboratory Instrument Calibration Certificate Template - PDF - HTML

Pressure Gauge Calibration Log Sheet - PDF - HTML

Temperature Sensor Calibration Report Format - PDF - HTML

Flow Meter Calibration Documentation Template - PDF - HTML

Weighing Scale Calibration Register Form - PDF - HTML

pH Meter Calibration Log Book Template - PDF - HTML

Dimensional Measuring Instrument Calibration Tracker - PDF - HTML

Torque Wrench Calibration Verification Sheet - PDF - HTML

Medical Device Calibration Compliance Form - PDF - HTML

Oven/Incubator Calibration Log Template - PDF - HTML

Spectrophotometer Calibration Audit Record - PDF - HTML

Introduction to Engineering Calibration Log Forms

An Engineering Calibration Log Form Template is a structured document used to record and track the calibration of instruments and equipment in engineering projects. It ensures accuracy, consistency, and compliance with industry standards by documenting calibration details systematically.

This form helps maintain the reliability and performance of engineering tools by providing a clear record of calibration activities.

Importance of Calibration in Engineering

Engineering calibration log forms are essential tools for maintaining accuracy and reliability in measurement instruments. Proper calibration ensures that engineering processes meet quality standards and safety regulations.

- Ensures Measurement Accuracy - Calibration minimizes errors by aligning instruments with recognized standards, which is critical for precise engineering outcomes.

- Enhances Equipment Performance - Regular calibration helps detect instrument drift or wear, maintaining optimal functionality and extending equipment life.

- Supports Compliance and Safety - Calibration documentation fulfills regulatory requirements and helps prevent failures that could compromise safety and project integrity.

Key Components of a Calibration Log Form

What are the essential elements of an Engineering Calibration Log Form Template? A calibration log form must include details such as equipment identification, calibration date, and technician information. These components ensure accurate tracking and maintenance of instrumentation performance over time.

Benefits of Using Calibration Log Templates

Using an Engineering Calibration Log Form Template streamlines the process of tracking equipment accuracy and maintenance schedules.

This template ensures consistent data recording, reducing human error and enhancing reliability. It simplifies compliance with industry standards by providing a clear, organized format for all calibration activities.

Essential Fields in an Engineering Calibration Log

An Engineering Calibration Log Form Template is vital for maintaining precise records of equipment calibration. It ensures accuracy and compliance in engineering processes by documenting essential details systematically.

- Equipment Identification - This field captures the unique ID or serial number of the equipment being calibrated to ensure traceability.

- Date of Calibration - Recording the exact date helps track calibration schedules and verifies the timeliness of the process.

- Calibration Results - This includes measurements and outcomes to confirm whether the equipment meets required standards.

Including these essential fields in a calibration log template guarantees reliable data management and supports quality control in engineering operations.

How to Customize Calibration Log Forms

To customize an engineering calibration log form template, start by identifying the specific equipment and parameters that need regular calibration tracking. Incorporate fields that capture critical details such as calibration date, technician name, measurement results, and equipment identification. Adjust the layout and sections to fit the workflow of your engineering team, ensuring easy data entry and accurate record-keeping.

Best Practices for Maintaining Calibration Records

Engineering calibration log form templates are essential tools for maintaining accurate and reliable calibration records.

Best practices for maintaining calibration records include using standardized log forms to ensure consistency and traceability. Clear documentation of calibration dates, equipment details, and technician signatures enhances accountability and audit readiness.

Compliance and Standards in Calibration Documentation

Engineering Calibration Log Form Templates are essential for maintaining accurate and consistent calibration records in compliance with industry standards. Proper documentation ensures traceability and reliability, supporting quality assurance and regulatory requirements.

- Ensures regulatory compliance - The template captures all necessary details to meet national and international calibration standards such as ISO 17025.

- Maintains traceability - It provides a systematic record of calibration activities, linking instruments to their calibration certificates and dates.

- Supports quality management - The log form helps organizations uphold internal and external audit requirements by standardizing calibration documentation.

Digital vs. Paper Calibration Log Forms

Engineering calibration log form templates are essential for maintaining accurate records of equipment performance and ensuring compliance with industry standards. Digital calibration log forms offer enhanced data accessibility, easy updates, and automated reminders, reducing the risk of human error compared to traditional paper forms. Paper calibration log forms provide a tangible backup and can be useful in environments with limited digital infrastructure, but they require more manual effort for data management and retrieval.