Equipment failure report forms document incidents of malfunction to ensure accurate tracking and timely resolution. These reports capture essential details such as the equipment involved, nature of the failure, and corrective actions taken. Effective use of these forms improves maintenance processes and prevents recurring issues.

Equipment Failure Report Form Sample PDF Viewer

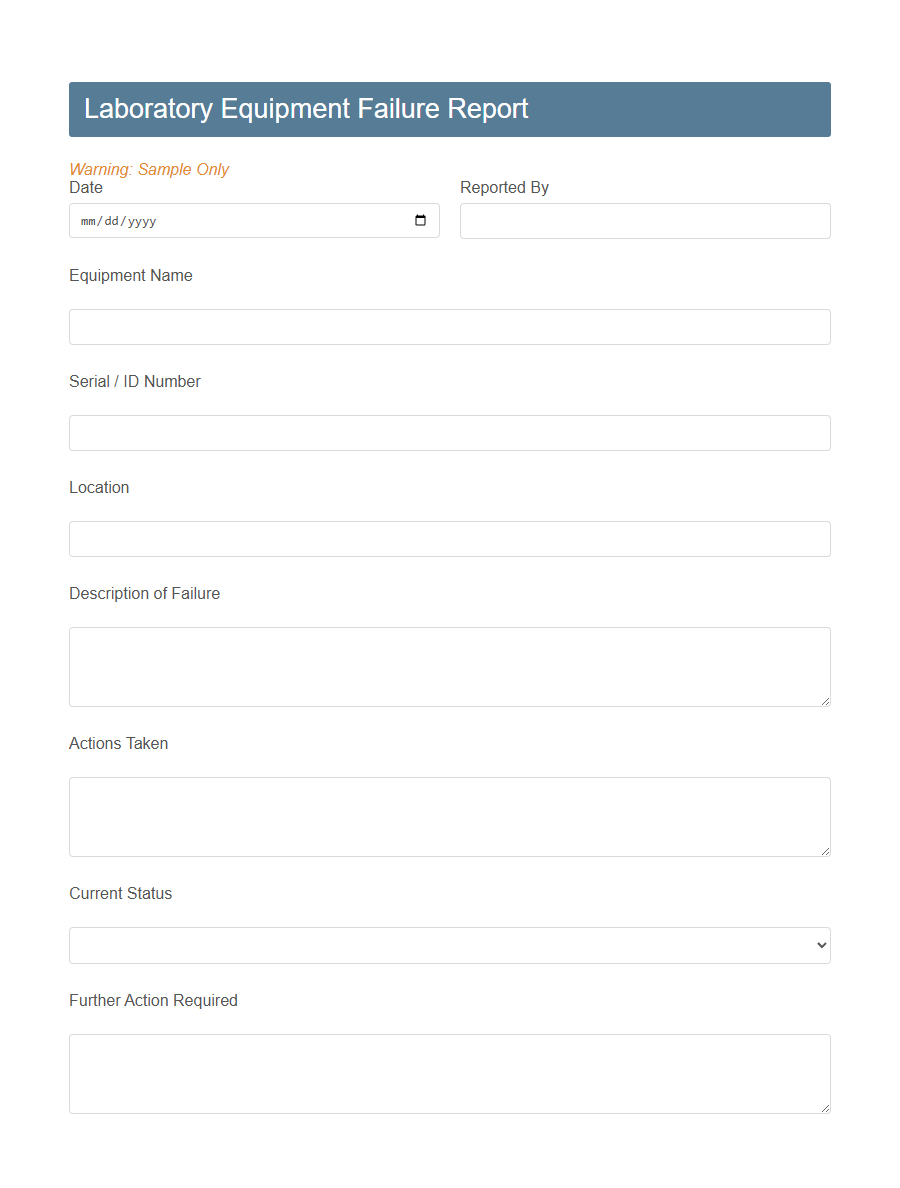

Image example of Equipment Failure Report Form:

Equipment Failure Report Form Samples

Laboratory Equipment Failure Report Template - PDF - HTML

Medical Device Incident Report Form - PDF - HTML

Industrial Machine Breakdown Documentation - PDF - HTML

IT Hardware Failure Log Sheet - PDF - HTML

Construction Equipment Malfunction Report - PDF - HTML

Manufacturing Line Equipment Downtime Report - PDF - HTML

HVAC Unit Failure Report Template - PDF - HTML

Food Processing Equipment Incident Form - PDF - HTML

Power Tool Malfunction Report Sheet - PDF - HTML

Agricultural Machinery Breakdown Form - PDF - HTML

Audio-Visual Equipment Failure Report - PDF - HTML

Scientific Instrument Failure Documentation - PDF - HTML

Mining Equipment Incident Report Template - PDF - HTML

Introduction to Equipment Failure Report Forms

An Equipment Failure Report Form is a crucial document used to record details of machinery malfunctions. It helps identify the root causes of failures and supports timely maintenance actions. Proper documentation ensures improved equipment reliability and minimizes downtime.

Purpose and Importance of Equipment Failure Reporting

Equipment Failure Report Forms are essential for documenting and analyzing malfunctions to prevent future breakdowns. Reporting failures promptly helps maintain safety standards and optimize operational efficiency.

- Purpose - To provide a structured method for recording details of equipment failures for thorough investigation.

- Importance - Enables early detection of recurring issues, reducing downtime and repair costs.

- Safety Enhancement - Ensures that potential hazards are identified and mitigated to protect personnel and assets.

Key Components of an Equipment Failure Report Form

An Equipment Failure Report Form is essential for documenting detailed information about equipment malfunctions.

It helps organizations identify failure patterns and implement corrective actions to prevent future breakdowns.

Key components of an Equipment Failure Report Form include equipment identification and failure description.

These sections capture the specific machine or part affected and provide a clear explanation of the failure event.

The date and time of failure and the location of the equipment are critical components.

They establish the context for the failure, aiding in timely response and tracking maintenance history.

Details about operator information and reported symptoms are vital.

This information helps in understanding the operational conditions leading to the failure and assists technicians during diagnosis.

Cause analysis and corrective actions sections are integral to the form.

They allow for documenting the root cause of the failure and the steps taken to fix the issue, preventing recurrence.

Documentation of downtime and impact on operations is often included.

This helps quantify the effect of the equipment failure on productivity and guides resource allocation for repairs.

Space for signatures and approvals ensures accountability and confirms the report has been reviewed.

This formalizes the documentation process and supports compliance with maintenance protocols.

Types of Equipment Failures Commonly Reported

Equipment Failure Report Forms frequently document mechanical failures such as broken gears, worn-out bearings, and motor malfunctions. Electrical issues like short circuits, power surges, and faulty wiring are also commonly reported. Operational errors, including sensor malfunctions and software glitches, often appear in these reports as well.

Step-by-Step Guide to Completing the Report Form

Completing an Equipment Failure Report Form ensures accurate documentation of any malfunction or breakdown. This helps in timely maintenance and prevents future failures.

Start by filling out basic information such as date, time, and location of the failure. Include the equipment name, model number, and identification details for precise tracking.

Describe the nature of the failure clearly and concisely. Note specific symptoms and any unusual noises, smells, or behavior observed before or during the failure.

Record who discovered the failure and who was notified. This maintains a clear communication trail to address the issue promptly.

List any immediate actions taken to mitigate damage or safety risks. Mention whether the equipment was shut down, repaired temporarily, or isolated.

Attach relevant photos, logs, or diagnostic reports if available. Visual evidence supports the written description and helps technicians diagnose the problem.

Review all entries for completeness and accuracy before submitting the report. A well-documented form speeds up repair processes and reduces downtime.

Best Practices for Accurate Failure Documentation

How can accurate failure documentation improve equipment maintenance? Precise records help identify recurring issues and inform timely repairs. Clear and detailed information reduces downtime and enhances asset reliability.

What details are essential to include in an Equipment Failure Report Form? Include the equipment identification, failure description, date, and operating conditions. This information enables effective root cause analysis and corrective actions.

Why is it important to use standardized terminology in failure reports? Standard terms ensure consistency and clarity across teams and departments. They facilitate better communication and prevent misunderstandings about equipment issues.

How does timely reporting benefit equipment failure management? Prompt documentation allows quick response to failures, minimizing further damage. Early intervention can reduce repair costs and extend equipment lifespan.

What role does staff training play in improving failure report accuracy? Well-trained personnel understand how to recognize and document failures properly. Training promotes thorough and precise reporting, leading to more effective maintenance strategies.

Common Mistakes to Avoid in Equipment Failure Reports

Equipment failure report forms are essential for documenting issues accurately and facilitating timely repairs. Common mistakes include incomplete information and unclear descriptions that hinder effective troubleshooting.

Ensure all fields are thoroughly completed with precise and detailed information to avoid delays in the repair process.

Integrating Report Forms with Maintenance Systems

Integrating Equipment Failure Report Forms with maintenance systems streamlines data collection and accelerates troubleshooting processes. This integration enhances the accuracy of maintenance records and supports proactive equipment management.

- Real-time Data Synchronization - Linking report forms directly to maintenance systems ensures immediate updating of equipment status and failure details.

- Automated Work Order Generation - Integration allows automatic creation of maintenance tasks based on reported failures, reducing manual entry and response times.

- Improved Analytics and Reporting - Combining failure data with maintenance histories enables comprehensive analysis to identify recurring issues and optimize repair strategies.

Role of Failure Reports in Preventive Maintenance

Failure reports play a crucial role in identifying and addressing equipment issues before they lead to major breakdowns, enhancing the effectiveness of preventive maintenance programs.

- Early Detection - Failure reports provide detailed insights into equipment malfunctions that enable early identification of potential problems.

- Data-Driven Decisions - The information collected from failure reports helps maintenance teams prioritize maintenance tasks based on actual equipment conditions.

- Continuous Improvement - Failure reports support the refinement of maintenance schedules and procedures by highlighting recurring issues and their root causes.

Consistent use of equipment failure report forms strengthens preventive maintenance by reducing downtime and extending machinery lifespan.