A Stock Replenishment Request Form streamlines inventory management by facilitating timely restocking of essential items. This form captures critical details such as product name, quantity required, and approval signatures to ensure accurate and efficient order processing. Implementing these examples can help businesses maintain optimal stock levels and prevent supply shortages.

Stock Replenishment Request Form Sample PDF Viewer

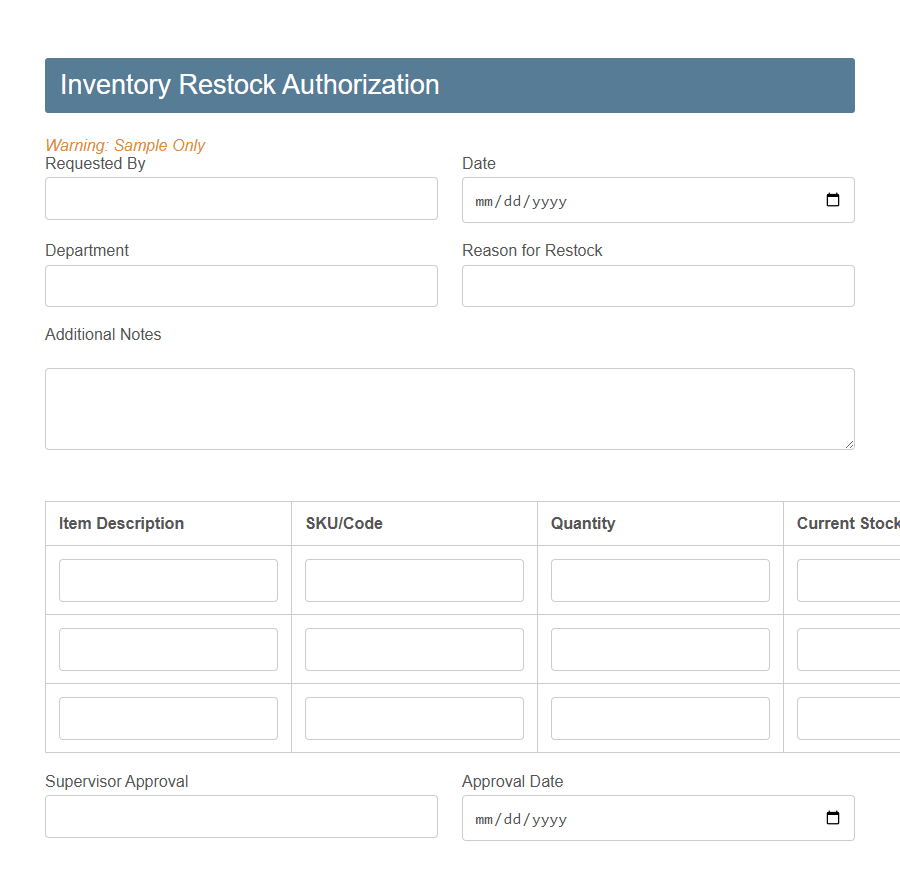

Image example of Stock Replenishment Request Form:

Stock Replenishment Request Form Samples

Inventory Restock Authorization Template - PDF - HTML

Warehouse Supply Replenishment Request Form - PDF - HTML

Retail Shelf Stocking Request Template - PDF - HTML

Office Supplies Restock Form - PDF - HTML

Manufacturing Raw Materials Replenishment Form - PDF - HTML

Restaurant Ingredient Reorder Request Slip - PDF - HTML

Laboratory Chemical Replenishment Request - PDF - HTML

Hospital Pharmacy Inventory Restock Form - PDF - HTML

E-commerce Pick and Pack Stock Request Template - PDF - HTML

Automotive Parts Replenishment Authorization - PDF - HTML

Construction Materials Restock Request Sheet - PDF - HTML

School Classroom Supplies Replenishment Form - PDF - HTML

Hotel Linen Stock Restock Request - PDF - HTML

Introduction to Stock Replenishment Request Forms

A Stock Replenishment Request Form is a crucial tool used in inventory management to ensure timely restocking of items.

This form helps employees or departments request additional stock when inventory levels run low. It streamlines communication between the requesting party and the procurement or warehouse team, promoting efficient inventory control.

Importance of Timely Inventory Replenishment

Timely inventory replenishment ensures that stock levels are maintained to meet customer demand and prevent sales losses. A Stock Replenishment Request Form facilitates accurate and prompt ordering, reducing the risk of stockouts and overstock situations.

Efficient inventory management through timely replenishment enhances operational flow and customer satisfaction.

Key Components of a Stock Replenishment Request Form

A Stock Replenishment Request Form is essential for maintaining adequate inventory levels in a business.

It helps streamline the process of ordering and receiving stock by providing clear and organized information.

The key components of the form include item details such as product name, SKU, and quantity needed.

These details ensure accuracy and prevent errors during the replenishment process.

Supplier information is another critical element, specifying the preferred vendor and contact details.

This facilitates quick communication and order placement with suppliers.

The form also typically includes authorization fields for approvals from relevant personnel.

This control helps manage inventory spending and prevents unauthorized orders.

Additional sections may cover delivery instructions and desired delivery dates.

These components help coordinate logistics and ensure timely stock arrival.

Step-by-Step Guide to Completing the Form

Begin by entering the product details, including item name, code, and current stock levels. Next, specify the quantity needed and the preferred delivery date to ensure timely restocking. Finally, review the information for accuracy before submitting the form to the inventory management team.

Common Mistakes to Avoid in Stock Replenishment Requests

Stock replenishment request forms often contain errors such as inaccurate item quantities, leading to overstock or stockouts. Failing to provide complete product details can delay processing and cause confusion in inventory management. Ignoring approval protocols or missing signatures may result in unauthorized orders and disrupt supply chain operations.

Benefits of Using Standardized Request Forms

Using a Stock Replenishment Request Form streamlines inventory management and reduces errors in ordering processes.

- Improved Accuracy - Standardized forms minimize miscommunication by providing clear fields for necessary information.

- Faster Processing - Consistent formats speed up approval and fulfillment workflows.

- Better Trackability - Uniform documentation makes it easier to audit and analyze stock requests over time.

Adopting standardized request forms enhances efficiency and control in inventory replenishment operations.

Digital vs. Paper Stock Replenishment Forms

Stock replenishment request forms are essential tools for managing inventory efficiently and preventing stockouts. Comparing digital and paper forms reveals key differences in speed, accuracy, and environmental impact.

- Digital Forms Enhance Efficiency - Digital stock replenishment request forms streamline the submission and approval process through automated workflows.

- Paper Forms Increase Error Risk - Paper-based forms are prone to handwriting errors and misplacement, leading to delays in inventory restocking.

- Digital Solutions Support Sustainability - Using digital forms reduces paper consumption, contributing to environmentally friendly business practices.

Integrating Stock Request Forms with Inventory Management Systems

How does integrating stock replenishment request forms with inventory management systems improve efficiency? Integrating these forms streamlines the process of tracking inventory levels and automates order requests. This reduces manual errors and ensures timely restocking to meet demand.

Best Practices for Streamlining Stock Replenishment

Efficient stock replenishment is crucial for maintaining optimal inventory levels and minimizing stockouts. Implementing a well-designed Stock Replenishment Request Form enhances accuracy and speeds up the restocking process.

- Standardize the Request Format - Use a consistent, easy-to-fill form to reduce errors and ensure all necessary information is captured with every request.

- Integrate Real-Time Inventory Data - Link the form to your inventory system to provide immediate visibility of stock levels and prevent over-ordering or shortages.

- Automate Approval Workflows - Set up automated routing and approval steps to accelerate processing times and ensure accountability in replenishment decisions.