Tolerance deviation request form templates help document and manage acceptable variations in product specifications. These forms ensure clear communication between engineering and quality control teams to maintain production standards. Using a standardized template streamlines the approval process and minimizes errors in manufacturing.

Tolerance Deviation Request Form Template Sample PDF Viewer

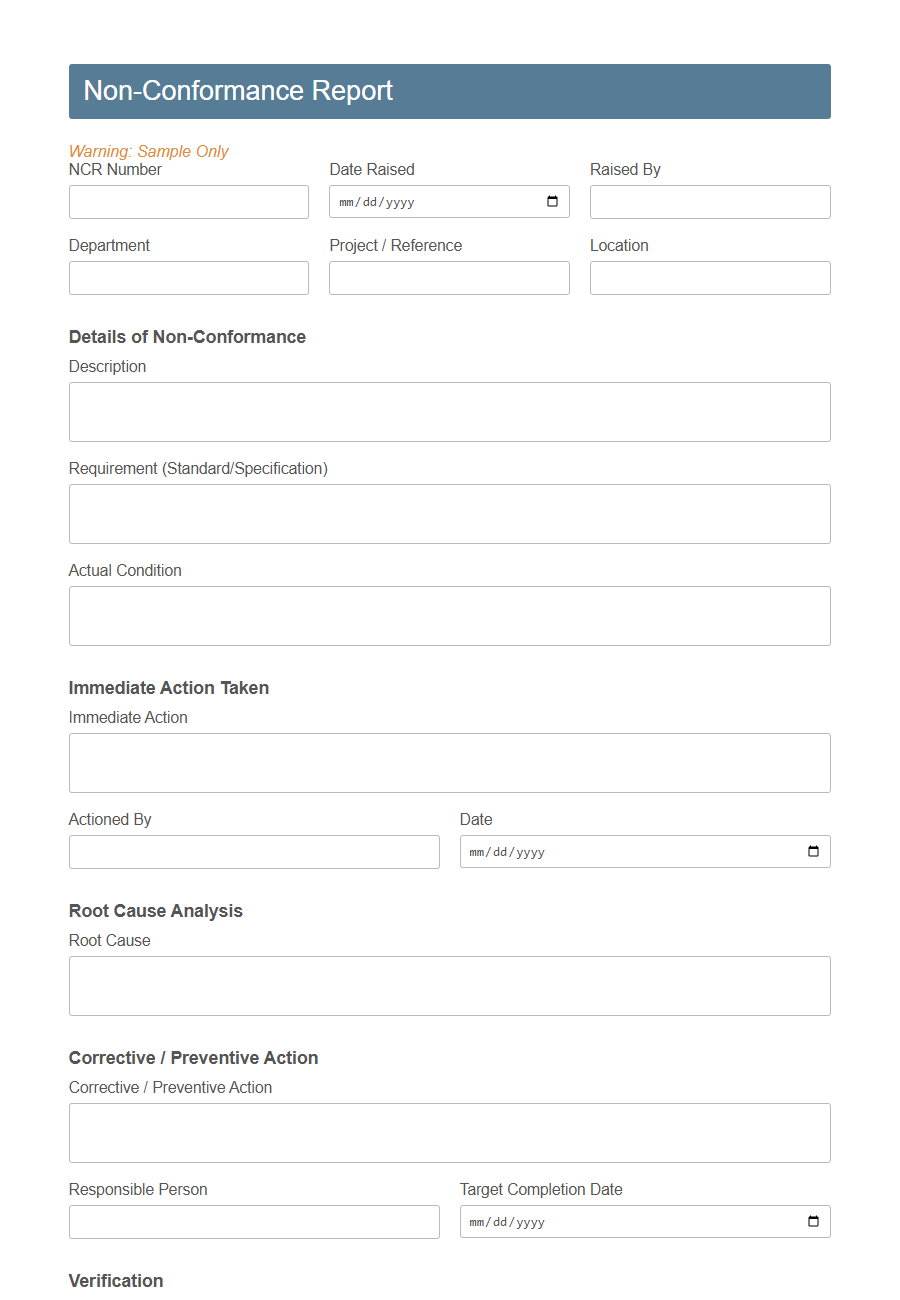

Image example of Tolerance Deviation Request Form Template:

Tolerance Deviation Request Form Template Samples

Non-Conformance Report Template - PDF - HTML

Engineering Change Request - PDF - HTML

Material Deviation Approval - PDF - HTML

Supplier Concession Request Template - PDF - HTML

Product Waiver Application Template - PDF - HTML

Temporary Deviation Permit - PDF - HTML

Manufacturing Variance Request Template - PDF - HTML

Quality Control Deviation Notice Template - PDF - HTML

Component Specification Deviation - PDF - HTML

Design Exception Request Template - PDF - HTML

Process Deviation Log Sheet Template - PDF - HTML

Acceptance Criteria Waiver - PDF - HTML

Assembly Tolerance Adjustment Request Template - PDF - HTML

Equipment Calibration Deviation Report Template - PDF - HTML

Out-of-Tolerance Condition Notification Template - PDF - HTML

Understanding Tolerance Deviation Requests

Understanding Tolerance Deviation Requests is essential for managing product quality and ensuring compliance with specifications. This process helps identify allowable variations while maintaining overall functionality and safety.

- Purpose - Tolerance Deviation Requests document and authorize acceptable deviations from standard measurements or specifications.

- Evaluation - Each request undergoes a thorough review to assess potential impacts on performance and safety.

- Approval - Authorized personnel approve or reject deviation requests based on technical and quality criteria.

Importance of a Tolerance Deviation Request Form

A Tolerance Deviation Request Form is essential for documenting acceptable variations from specified engineering or manufacturing standards. This form ensures clear communication between quality control and production teams, preventing errors and maintaining product integrity. Proper use of this document helps organizations manage risks and comply with regulatory requirements efficiently.

Key Components of the Tolerance Deviation Request Form Template

What are the key components of the Tolerance Deviation Request Form Template? The form typically includes fields for identifying the part or process involved and the specific tolerance limits being requested for deviation. It also requires detailed justification for the deviation and any potential impacts on quality or performance.

Which sections capture the approval process in the Tolerance Deviation Request Form Template? Approval sections usually contain spaces for signatures, dates, and roles of the personnel authorizing the deviation. This ensures accountability and proper documentation of decisions made.

How does the form ensure traceability of the tolerance deviation request? The template includes unique identification numbers or request codes to track each submission. This feature helps maintain organized records and facilitates easy retrieval of past requests.

What supporting information is commonly requested on the Tolerance Deviation Request Form? The form often asks for related documentation such as engineering drawings, process control plans, or previous deviation records. These details help reviewers thoroughly assess the potential impact of the requested deviation.

Why is a detailed description of the deviation necessary in the form? Providing a clear explanation helps clarify exactly what tolerance parameters are changing and why. This transparency aids in the evaluation process and ensures all stakeholders understand the scope of the deviation.

When to Use a Tolerance Deviation Request Form

A Tolerance Deviation Request Form is used when a product or component does not meet the specified tolerance limits but remains functional and safe. It helps document and seek approval for minor deviations to avoid unnecessary rework or delays. This form is essential during quality inspections, manufacturing processes, or when handling non-conforming materials.

Step-by-Step Guide to Completing the Form

The Tolerance Deviation Request Form Template ensures clarity when requesting exceptions to standard tolerances. Follow this step-by-step guide to complete the form accurately and efficiently.

- Identify the Part or Process - Clearly specify the component or procedure for which the tolerance deviation is requested.

- Describe the Deviation - Provide detailed information about the requested tolerance limits and how they differ from the standard requirements.

- Justify the Request - Explain the reasons for the deviation, including any impact on quality, cost, or delivery timelines.

- Attach Supporting Documentation - Include relevant drawings, test data, or analysis that support the deviation request.

- Obtain Necessary Approvals - Secure signatures from authorized personnel to ensure the deviation is officially reviewed and authorized.

- Record and Distribute the Form - Submit the completed form to the designated department and keep a copy for records and future reference.

Common Reasons for Tolerance Deviation Requests

A Tolerance Deviation Request Form Template is used to document and seek approval for deviations from specified tolerance limits in manufacturing or engineering processes.

It helps ensure quality standards are maintained while allowing flexibility for minor variations that do not impact product functionality or safety.

Common reasons for tolerance deviation requests include equipment limitations that prevent achieving exact measurements.

Other frequent causes are material inconsistencies or environmental factors that affect production accuracy.

Design modifications or updates may also require tolerance adjustments to accommodate new specifications.

Operator error or calibration issues can lead to deviations that need formal approval through this request process.

Approval Workflow for Tolerance Deviation Requests

The Tolerance Deviation Request Form Template streamlines the process of managing approval workflows for tolerance deviations.

This form captures detailed information about the deviation and routes the request automatically to the designated approvers. Approvals are tracked systematically to ensure compliance and accountability throughout the review process.

Benefits of Standardized Request Forms

Using a standardized Tolerance Deviation Request Form template streamlines the approval process and ensures consistent documentation across all projects. This approach improves communication and reduces errors in managing tolerance deviations.

- Improved Clarity - Standardized forms provide a clear structure that simplifies the submission and review of deviation requests.

- Faster Approval - Predefined fields and guidelines accelerate decision-making by eliminating ambiguous information.

- Enhanced Compliance - Consistent documentation supports regulatory requirements and quality control audits effectively.

Standardized request forms create a reliable and efficient workflow for handling tolerance deviations.

Frequently Asked Questions about Tolerance Deviation Forms

A Tolerance Deviation Request Form is used to formally document and seek approval for deviations from specified tolerance limits in manufacturing or engineering processes. It ensures that any deviations are assessed for impact on quality and safety before proceeding.

This form helps maintain product integrity while allowing flexibility in production when minor deviations occur.

Frequently asked questions often address how to fill out the form, what approvals are required, and when to submit the request.

Understanding these FAQs ensures proper use and timely processing of tolerance deviation requests.

Common questions include the acceptable range for deviations and who has the authority to approve the request.

Clear guidelines help prevent production delays and quality issues.

Many users ask whether the form applies to all types of components or only critical dimensions.

The form typically applies to any parameters where tolerance limits are defined and deviations could affect performance.