Materials submittal forms in engineering streamline project documentation by specifying detailed information about materials used. These forms ensure compliance with design requirements, quality standards, and regulatory guidelines. Clear examples of materials submittal forms enhance communication between contractors, suppliers, and project engineers.

Materials Submittal Form (Engineering) Sample PDF Viewer

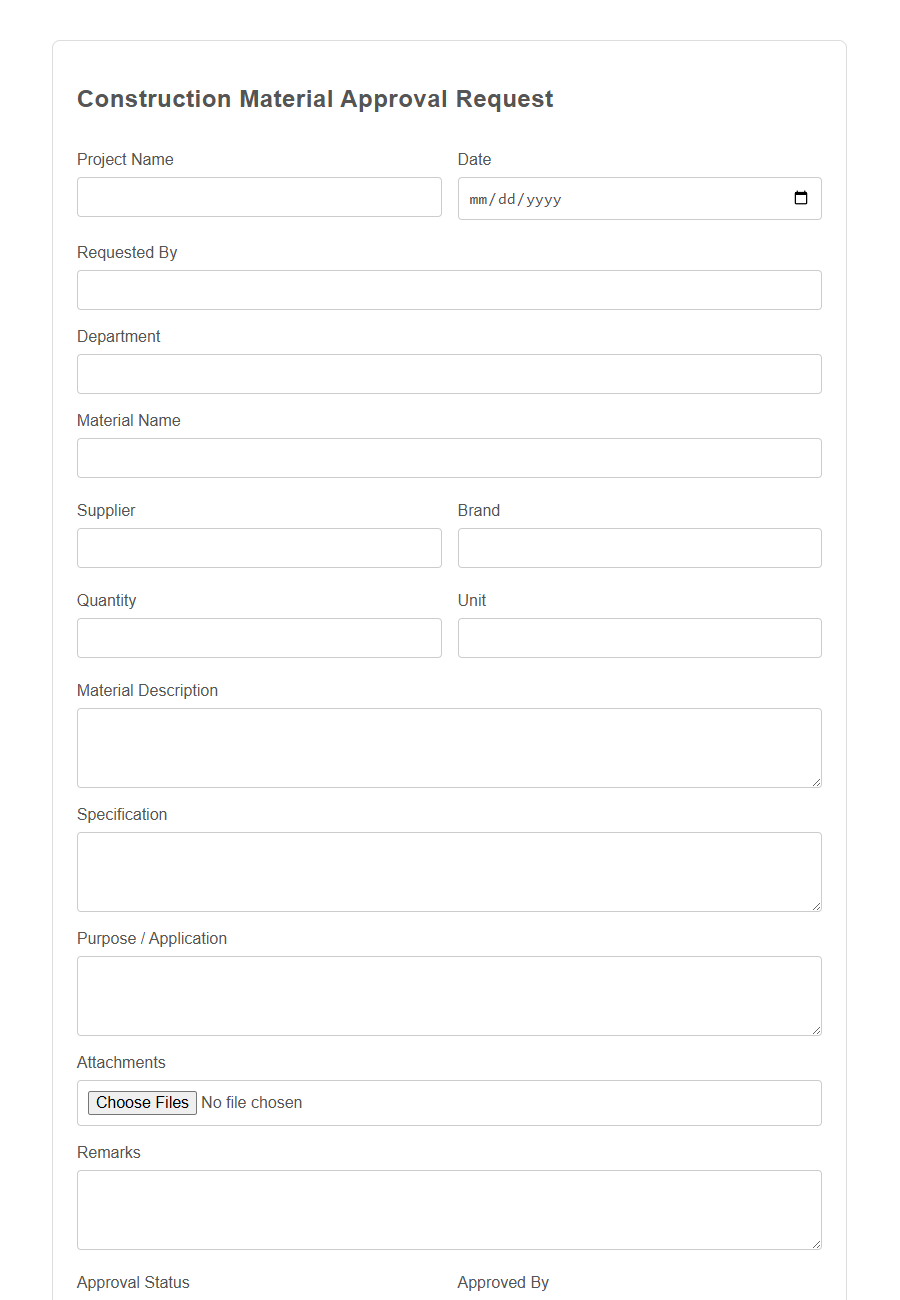

Image example of Materials Submittal Form (Engineering):

Materials Submittal Form (Engineering) Samples

Construction Material Approval Request Template - PDF - HTML

Engineering Material Data Sheet Submission - PDF - HTML

Material Specification Compliance Form - PDF - HTML

Vendor Material Submittal Checklist - PDF - HTML

Laboratory Test Results Submission Template - PDF - HTML

Material Certification Document Template - PDF - HTML

Product Technical Data Submittal Form - PDF - HTML

Pre-Construction Material Review Template - PDF - HTML

Material Safety Data Sheet (MSDS) Submittal Form - PDF - HTML

Engineering Materials Sample Transmittal - PDF - HTML

Material Source Approval Request Form - PDF - HTML

Construction Site Material Receipt Verification - PDF - HTML

Material Change Request Document - PDF - HTML

Introduction to Materials Submittal Forms

Materials Submittal Forms are essential documents in engineering projects used to verify the compliance and quality of materials before their approval and use.

They ensure that all materials meet project specifications and standards by providing detailed information such as material properties, certifications, and manufacturer details.

These forms facilitate clear communication between contractors, suppliers, and engineers, helping to maintain project integrity and prevent delays.

Materials Submittal Forms act as formal records that support quality assurance processes and help in tracking material usage throughout the project lifecycle.

Proper completion and review of these forms contribute to safer construction practices and enhance overall project management efficiency.

Purpose of Materials Submittal in Engineering Projects

The purpose of a Materials Submittal Form in engineering projects is to ensure that all materials meet specified standards and project requirements before use.

This form helps in verifying the quality, compatibility, and compliance of materials with design specifications. It serves as a critical checkpoint to prevent construction delays and maintain safety and performance standards throughout the project.

Key Components of a Materials Submittal Form

What are the key components of a Materials Submittal Form in engineering? A Materials Submittal Form typically includes detailed descriptions of the materials proposed for use, ensuring they meet project specifications. It also contains supplier information and relevant test certificates to verify quality and compliance.

Why is accuracy important in the details provided on a Materials Submittal Form? Accurate information helps in avoiding delays during project approval processes and ensures materials conform to design requirements. This precision supports effective communication between contractors, engineers, and suppliers.

How does the approval status section function in a Materials Submittal Form? The approval status indicates whether the submitted materials are accepted, rejected, or require modifications. This section streamlines decision-making and maintains record accuracy throughout the project.

What role do reference standards play in a Materials Submittal Form? Reference standards specify the codes and specifications materials must comply with, such as ASTM or ISO standards. Including these standards guarantees that all materials align with industry and project quality benchmarks.

Why is it essential to list the project and subcontractor details in a Materials Submittal Form? This information ensures traceability and accountability for the materials used in each project segment. Proper identification helps in managing orders and resolving any material-related issues efficiently.

Steps in the Materials Submittal Process

The Materials Submittal Form is a critical document used in engineering projects to ensure all materials meet specified standards before procurement and use. Following a structured process for materials submittal helps maintain project quality and compliance with design requirements.

- Preparation of Submittal Documentation - Compile detailed information including specifications, datasheets, and certifications for the intended materials.

- Submission for Review - Submit the completed form and supporting documents to the engineering team or client for evaluation and approval.

- Approval or Revision - Receive feedback and either obtain formal approval or make necessary revisions based on review comments.

Common Materials Requiring Submittals

The Materials Submittal Form in engineering is essential for documenting and approving materials before use in a project. It ensures all materials meet specified standards and project requirements.

- Concrete - Requires submittals to verify mix design, strength, and compliance with project specifications.

- Steel - Needs detailed certificates and mill test reports to confirm properties and quality.

- Electrical Components - Submittals include data sheets and approvals to ensure compatibility and safety.

Submitting accurate materials documentation helps maintain project quality and adherence to engineering standards.

Roles and Responsibilities in Submittal Management

The Materials Submittal Form in engineering serves as a critical document for verifying that all materials meet project specifications before procurement and use. The project engineer is responsible for preparing and reviewing the submittal to ensure accuracy and compliance with technical requirements. The procurement team must manage the submission process, track approvals, and coordinate with suppliers to maintain project timelines and quality standards.

Documentation and Supporting Information

The Materials Submittal Form in engineering serves as a critical document for verifying the specifications and quality of materials before approval. Proper documentation and supporting information ensure compliance with project requirements and standards.

- Specification Details - Clearly outlines the material properties, dimensions, and standards to confirm conformity with project demands.

- Compliance Certificates - Includes manufacturer certifications and test reports to validate material quality and regulatory adherence.

- Reference Drawings - Provides drawings or datasheets as visual confirmation of the material's intended application and compatibility.

Best Practices for Preparing Materials Submittals

When preparing a Materials Submittal Form in engineering, ensure all product specifications and relevant certifications are accurately detailed to facilitate clear communication with project stakeholders. Organize the information systematically, including manufacturer details, material standards, and test results, to streamline the review and approval process. Consistently update and verify the submittal documentation to maintain compliance with project requirements and industry standards.

Common Challenges and How to Address Them

Materials Submittal Forms in engineering projects often face challenges such as incomplete documentation and discrepancies between specified and submitted materials. These issues can lead to project delays and increased costs if not managed properly.

Ensuring thorough review protocols and clear communication with suppliers can effectively address these common challenges.