An Engineering Change Order (ECO) form template standardizes the documentation of modifications in engineering designs or processes. This template ensures clarity, traceability, and efficient communication among teams involved in implementing changes. Examples of ECO form templates illustrate varied formats and essential fields required to effectively manage engineering changes.

Engineering Change Order (ECO) Form Template Sample PDF Viewer

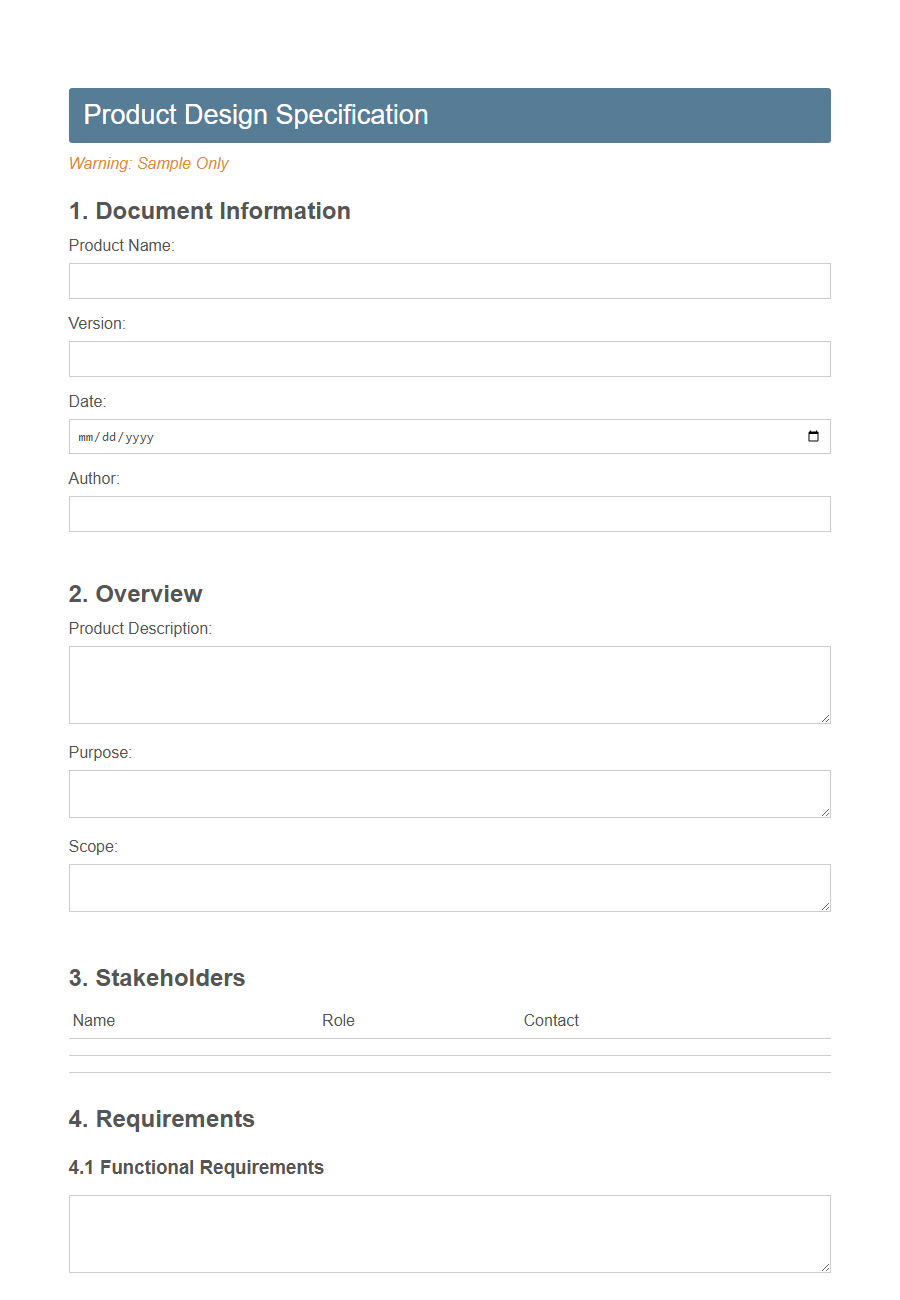

Image example of Engineering Change Order (ECO) Form Template:

Engineering Change Order (ECO) Form Template Samples

Product Design Specification Template - PDF - HTML

Bill of Materials (BOM) Revision Template - PDF - HTML

Change Impact Analysis Report Template - PDF - HTML

Component Obsolescence Notification Form - PDF - HTML

Design Review Meeting Minutes Template - PDF - HTML

Configuration Change Request Form - PDF - HTML

Drawing Revision Control Sheet - PDF - HTML

Prototype Approval Signoff Template - PDF - HTML

Supplier Notification of Change Template - PDF - HTML

Software Release Change Log Template - PDF - HTML

Tooling Modification Request Form - PDF - HTML

Manufacturing Process Change Report - PDF - HTML

Risk Assessment for Engineering Changes Template - PDF - HTML

Deviation/Concession Request Form - PDF - HTML

Corrective Action for ECO Implementation Template - PDF - HTML

Introduction to Engineering Change Orders (ECOs)

Engineering Change Orders (ECOs) are essential documents used to manage modifications in product design or manufacturing processes. They help ensure that all changes are systematically reviewed, approved, and implemented to maintain quality and consistency.

- Definition - An ECO is a formal request to alter specifications, drawings, or processes related to a product.

- Purpose - ECOs facilitate communication and documentation of changes to prevent errors and production delays.

- Process - The ECO process involves identifying, evaluating, approving, and executing changes in a controlled manner.

Utilizing an ECO form template streamlines change management by providing a standardized format for capturing all necessary information.

Importance of an Effective ECO Form

An effective Engineering Change Order (ECO) form is crucial for managing modifications in product design and manufacturing processes.

It ensures clear communication among engineering, production, and quality teams, reducing errors and delays. A well-structured ECO form streamlines the approval process and maintains accurate documentation for future reference.

Key Components of an ECO Form Template

An Engineering Change Order (ECO) form template includes key components such as a detailed description of the change, reason for the change, and its impact on the existing design or process. It also contains sections for approval signatures, effective dates, and revision numbers to ensure proper documentation and traceability. Clear identification fields like part numbers, drawing numbers, and change request originator are essential for accuracy and communication throughout the engineering process.

Steps Involved in the ECO Process

What are the key steps involved in the Engineering Change Order (ECO) process? The ECO process begins with identifying the need for a change and documenting it on the ECO form template. Next, the proposed change is reviewed, approved, and implemented while tracking all modifications carefully.

Types of Changes Managed by ECOs

Engineering Change Order (ECO) forms manage various types of changes including design modifications, material substitutions, and process updates. These changes ensure product improvements, compliance with standards, and cost-effective manufacturing adjustments.

ECOs help maintain clear documentation and control over all engineering alterations.

Best Practices for Designing an ECO Form

Design an Engineering Change Order (ECO) form template with clear sections for capturing detailed information such as change description, reasons, and approval signatures. Use standardized fields and checkboxes to simplify data entry and ensure consistency across submissions. Incorporate revision tracking and version control features to maintain a transparent audit trail throughout the change management process.

Common Mistakes to Avoid in ECO Documentation

Engineering Change Order (ECO) forms are critical for documenting modifications in product design or manufacturing processes. Properly completing these forms ensures clear communication and efficient implementation of changes.

- Inadequate Detail - Failing to provide comprehensive information can lead to misunderstandings and improper execution of the change.

- Missing Approvals - Omitting necessary signatures or approvals delays the change process and questions its validity.

- Poor Version Control - Not tracking revisions accurately can cause confusion and errors in applying the most current changes.

Digital vs. Paper-Based ECO Form Templates

Engineering Change Order (ECO) form templates are essential for documenting modifications in engineering processes, available in both digital and paper-based formats. Choosing between these formats impacts efficiency, accuracy, and traceability in managing engineering changes.

- Digital ECO Form Templates - These templates streamline the change process by enabling real-time updates and easy access across multiple departments.

- Paper-Based ECO Form Templates - Traditional forms rely on manual entry and physical storage, which can slow down communication and increase error risks.

- Traceability and Storage - Digital templates offer improved traceability with automated version control, while paper forms require meticulous manual filing to maintain records.

Sample Engineering Change Order Form Template

An Engineering Change Order (ECO) Form Template streamlines the process of documenting and approving modifications in engineering projects.

The Sample Engineering Change Order Form Template provides a clear layout for tracking essential details such as change description, reason, affected parts, and approval signatures. Using this template ensures consistency and accuracy in managing engineering changes across teams.