Calibration verification forms for engineering equipment ensure accurate measurement and optimal performance by documenting inspection results and adherence to standards. These forms provide a systematic approach to verify instruments, detect deviations, and schedule recalibrations for reliable operation. Utilizing examples from various engineering tools highlights best practices and enhances overall quality control.

Calibration Verification Form (Engineering Equipment) Sample PDF Viewer

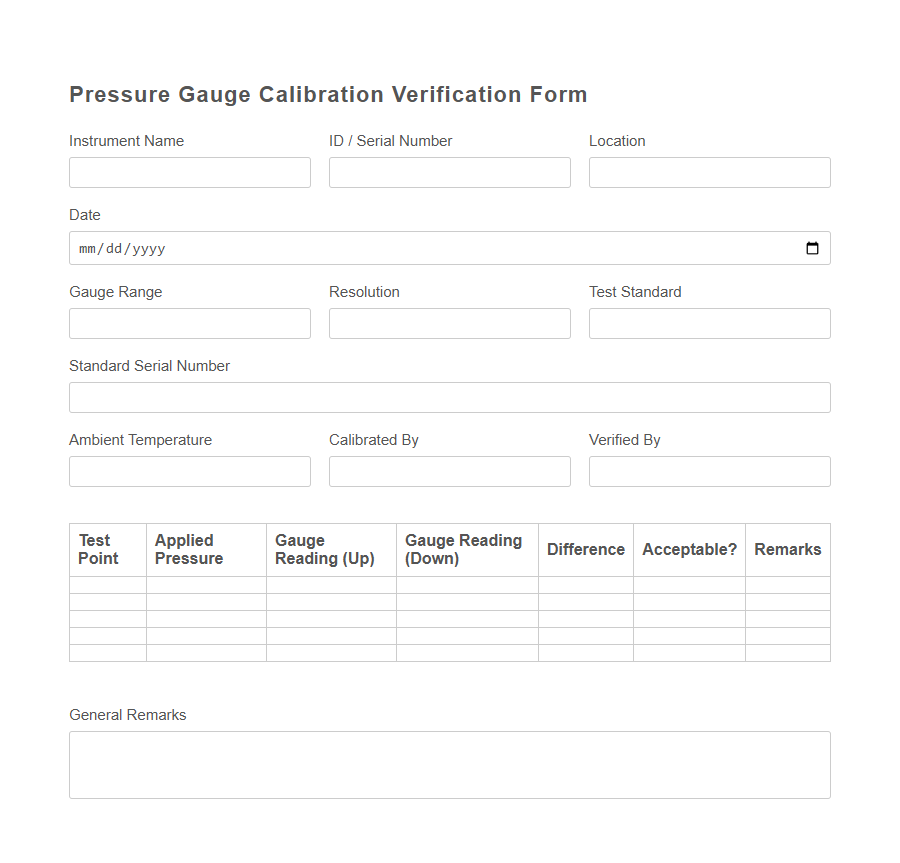

Image example of Calibration Verification Form (Engineering Equipment):

Calibration Verification Form (Engineering Equipment) Samples

Pressure Gauge Calibration Verification Form - PDF - HTML

Thermocouple Calibration Verification Template - PDF - HTML

Multimeter Calibration Verification Checklist - PDF - HTML

Flow Meter Calibration Verification Report - PDF - HTML

Weight Scale Calibration Verification Log - PDF - HTML

Torque Wrench Calibration Verification Sheet - PDF - HTML

Oscilloscope Calibration Verification Form - PDF - HTML

Infrared Thermometer Calibration Verification Template - PDF - HTML

Pipette Calibration Verification Report - PDF - HTML

Hardness Tester Calibration Verification Record - PDF - HTML

Gas Detector Calibration Verification Checklist - PDF - HTML

Analytical Balance Calibration Verification Form - PDF - HTML

Sound Level Meter Calibration Verification Log - PDF - HTML

Humidity Sensor Calibration Verification Sheet - PDF - HTML

Dimensional Caliper Calibration Verification Template - PDF - HTML

Introduction to Calibration Verification Forms

Calibration Verification Forms are essential documents used to confirm the accuracy and reliability of engineering equipment. These forms help track calibration status, ensuring that instruments meet specified standards and perform correctly. They provide a systematic approach to maintaining quality and compliance in engineering processes.

Importance of Calibration in Engineering Equipment

Calibration verification forms ensure engineering equipment maintains accurate and reliable measurements essential for quality control. Proper calibration prevents errors that can lead to costly defects, safety hazards, and operational inefficiencies. Regular verification upholds compliance with industry standards and enhances overall equipment performance.

Key Components of a Calibration Verification Form

What are the key components of a Calibration Verification Form for engineering equipment? A Calibration Verification Form typically includes fields for equipment identification, calibration dates, and the technician's signature. It also records the verification results and any necessary corrective actions taken during the calibration process.

Regulatory Requirements for Calibration Documentation

Calibration verification forms for engineering equipment are essential documents that ensure measurement accuracy and compliance with industry standards. These forms must meet strict regulatory requirements to provide traceability and maintain equipment reliability throughout its operational life.

Accurate calibration documentation supports audit readiness and helps organizations demonstrate adherence to quality management systems and regulatory bodies.

Step-by-Step Guide to Completing a Calibration Verification Form

Completing a Calibration Verification Form for engineering equipment ensures accuracy and compliance with industry standards. Following a clear, step-by-step process guarantees reliable calibration documentation.

- Identify Equipment - Record the specific engineering equipment details, including model and serial number, to ensure accurate tracking.

- Perform Calibration - Conduct the calibration procedures according to manufacturer and industry guidelines to verify equipment performance.

- Document Results - Enter the measurement data, deviations, and calibration status on the form to maintain a clear audit trail.

Common Errors in Calibration Records and How to Avoid Them

Calibration verification forms for engineering equipment are crucial for maintaining accuracy and reliability in measurements. Common errors in calibration records can lead to improper equipment performance and compromised data integrity.

- Incomplete Data Entries - Missing details such as date, technician name, or equipment ID hinder traceability and accountability.

- Incorrect Calibration Values - Recording wrong reference standards or measurement results causes inaccurate calibration outcomes.

- Lack of Signature or Authorization - Absence of proper approvals can invalidate the calibration process and fail audits.

Thorough documentation, double-checking entries, and enforcing proper authorization protocols help avoid these errors in calibration records.

Best Practices for Verification and Validation

Calibration Verification Forms for engineering equipment ensure accurate measurement standards and maintain equipment reliability. Best practices for verification and validation involve systematic documentation, consistent procedures, and thorough review processes.

- Consistent Documentation - Maintain detailed and standardized records to ensure traceability and accountability throughout the verification process.

- Standardized Procedures - Use predefined methods and checklists to conduct calibration consistently and minimize errors.

- Thorough Review Processes - Implement multiple levels of review to validate results and confirm equipment performance meets specified requirements.

Digital vs. Paper Calibration Verification Forms

Calibration verification forms are essential tools for ensuring the accuracy and reliability of engineering equipment.

Digital calibration verification forms offer streamlined data entry, automatic error checking, and easier storage compared to traditional paper forms. Paper forms, while simple to use, are prone to manual errors, require more physical storage space, and can slow down the verification process.

Audit and Traceability Considerations

The Calibration Verification Form for engineering equipment is essential for maintaining measurement accuracy and reliability.

It serves as a documented record during audits, demonstrating compliance with industry standards. Traceability is ensured by linking calibration results to recognized national or international standards, providing confidence in measurement integrity.