A comprehensive wind turbine maintenance checklist form ensures efficient inspection and upkeep of turbine components to maximize performance and prevent breakdowns. Regularly monitoring blade condition, lubrication levels, and electrical systems helps identify potential issues early. Using a detailed checklist streamlines maintenance processes, enhances safety, and extends the operational lifespan of wind turbines.

Wind Turbine Maintenance Checklist Form Sample PDF Viewer

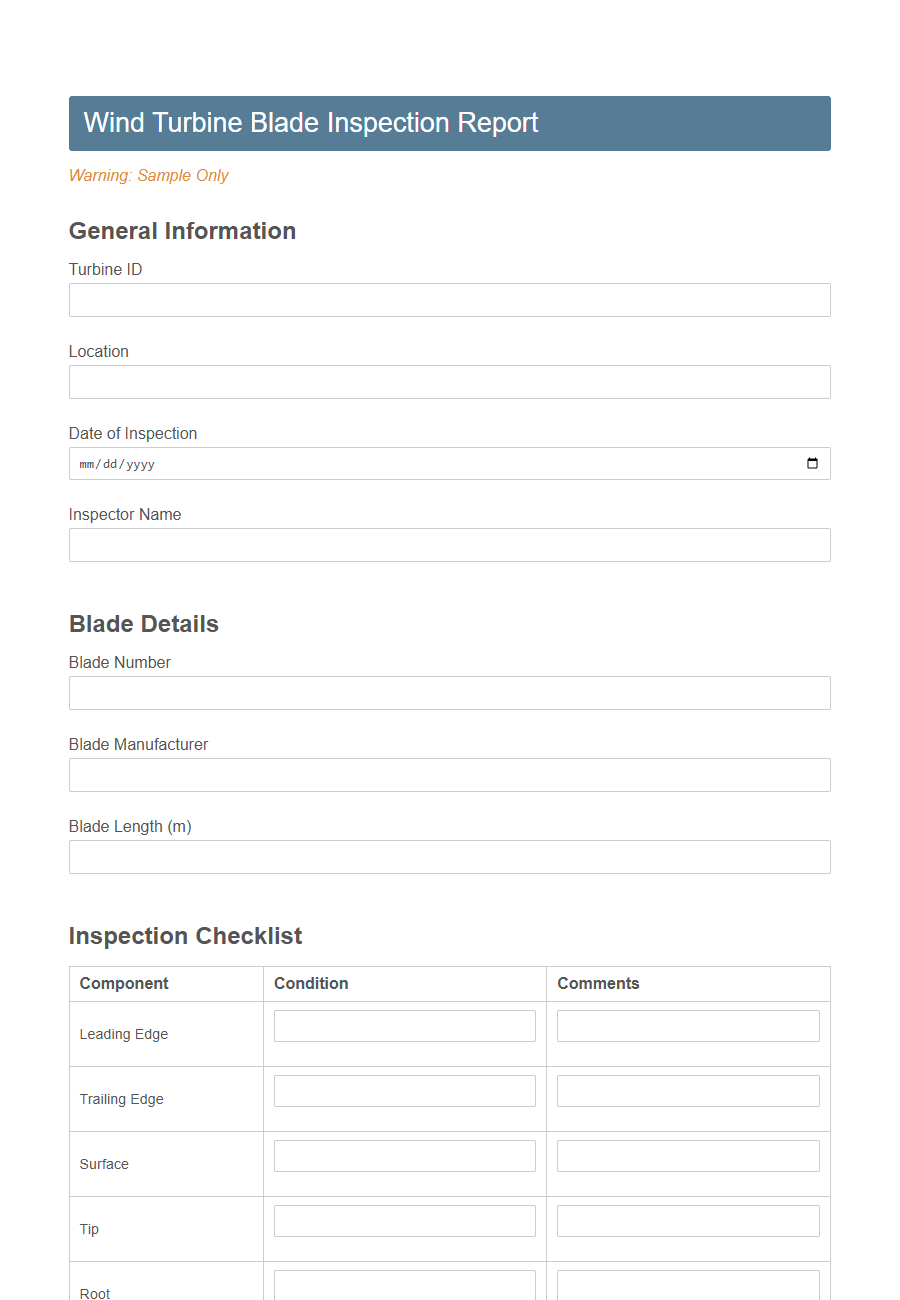

Image example of Wind Turbine Maintenance Checklist Form:

Wind Turbine Maintenance Checklist Form Samples

Wind Turbine Blade Inspection Report Template - PDF - HTML

Wind Turbine Gearbox Oil Analysis Log - PDF - HTML

Wind Turbine Annual Safety Audit Checklist - PDF - HTML

Wind Turbine Tower Bolt Torque Record Sheet - PDF - HTML

Wind Turbine Nacelle Temperature Monitoring Log - PDF - HTML

Wind Turbine Preventive Maintenance Task List - PDF - HTML

Wind Turbine Electrical System Testing Form - PDF - HTML

Wind Turbine Vibration Monitoring Checklist - PDF - HTML

Wind Turbine SCADA Data Review Log - PDF - HTML

Wind Turbine Emergency Shutdown Procedure Record - PDF - HTML

Wind Turbine Lightning Protection System Inspection Form - PDF - HTML

Wind Turbine Lubrication Schedule Checklist - PDF - HTML

Wind Turbine Yaw System Maintenance Report - PDF - HTML

Wind Turbine Hydraulic System Inspection Log - PDF - HTML

Wind Turbine Environmental Compliance Monitoring Sheet - PDF - HTML

Introduction to Wind Turbine Maintenance Checklist Forms

Wind turbine maintenance checklist forms are essential tools for ensuring the efficient operation and longevity of wind energy systems. These forms help technicians systematically verify all critical components during routine inspections.

- Standardized Inspection Process - The checklist provides a consistent framework for evaluating the condition of turbine parts and systems.

- Safety Assurance - It ensures that safety protocols are followed to protect maintenance personnel and equipment.

- Performance Optimization - Regular use of the checklist aids in identifying issues early, minimizing downtime and maximizing energy output.

Importance of Regular Wind Turbine Maintenance

Regular wind turbine maintenance ensures optimal performance and extends the lifespan of the equipment. It helps identify and address potential issues before they lead to costly breakdowns or safety hazards. Consistent upkeep maximizes energy efficiency and supports reliable power generation.

Key Components Covered in the Checklist

Wind turbine maintenance checklist forms ensure systematic inspection and upkeep of vital turbine parts. These checklists help maintain optimal performance and prevent unexpected breakdowns.

- Blades Inspection - Examines blade surface for cracks, erosion, and structural damage to ensure aerodynamic efficiency.

- Gearbox Check - Monitors lubrication levels and detects wear or overheating to avoid mechanical failures.

- Electrical System Review - Tests wiring, connectors, and control systems to maintain consistent power output and safety.

Pre-Maintenance Safety Procedures

Pre-maintenance safety procedures are critical to ensuring the protection of personnel and equipment during wind turbine servicing. Proper checks prevent accidents and maintain operational integrity before any maintenance activity begins.

- Lockout/Tagout Verification - Confirm all energy sources are isolated and properly tagged to prevent accidental startup of the turbine.

- Personal Protective Equipment (PPE) Inspection - Ensure all maintenance personnel are equipped with the required safety gear, including helmets, gloves, and harnesses.

- Weather Condition Assessment - Evaluate current and forecasted weather to determine if conditions are safe for maintenance work at height.

Following these safety steps reduces risk and promotes a secure maintenance environment for wind turbine operations.

Inspection of Mechanical Systems

Wind turbine maintenance checklist forms prioritize the inspection of mechanical systems to ensure optimal performance and safety.

Regular inspection of mechanical components such as gears, bearings, and shafts identifies wear and potential failures early. Thorough checks help prevent costly breakdowns and extend the turbine's operational life.

Electrical System Checks and Documentation

A Wind Turbine Maintenance Checklist Form ensures all electrical system components are thoroughly inspected for safety and performance. It includes detailed checks on wiring integrity, control panels, and electrical connections to prevent faults and downtime. Proper documentation of these inspections supports compliance with industry standards and facilitates efficient troubleshooting.

Blade and Rotor Inspection Guidelines

Wind turbine blade and rotor inspection is critical for ensuring optimal performance and preventing costly downtime. Regular assessments focus on identifying cracks, erosion, and any physical damage that could impair efficiency.

Inspect blades for surface defects, erosion, leading edge damage, and secure attachment to the rotor hub.

Lubrication and Fluid Level Monitoring

Wind turbine maintenance requires regular lubrication and fluid level monitoring to ensure optimal performance and longevity.

A detailed lubrication and fluid level monitoring checklist helps technicians keep track of oil, grease, and hydraulic fluids, preventing mechanical failures. Proper lubrication reduces friction and wear on moving parts, while consistent fluid level checks avoid overheating and system malfunctions.

Record-Keeping and Reporting Standards

How does the Wind Turbine Maintenance Checklist Form support effective record-keeping and reporting standards? The form ensures consistent documentation of all maintenance activities, enabling accurate tracking of work performed. It helps maintain compliance with regulatory requirements by providing a standardized format for detailed reporting.

Why is precise record-keeping critical in wind turbine maintenance? Accurate records allow for timely identification of recurring issues and facilitate predictive maintenance strategies. Thorough documentation also aids in auditing and verifying that all safety protocols have been followed.

What role does the checklist form play in improving communication among maintenance teams? It creates a clear, uniform record that can be easily reviewed by different stakeholders. This transparency supports better coordination and decision-making throughout the maintenance process.

How does the checklist contribute to long-term asset management? By systematically recording maintenance tasks, it helps track the turbine's condition over time. This data is essential for planning repairs, budgeting, and extending the equipment's operational lifespan.

In what way does the checklist form enhance accountability during maintenance operations? It assigns responsibility by requiring signatures or confirmations from personnel completing each task. This practice promotes careful attention to detail and reduces the risk of oversight or errors.