A wind turbine inspection checklist form ensures thorough evaluation of all critical components, promoting operational efficiency and safety. Regular inspections help identify potential issues early, reducing downtime and maintenance costs. This article provides a comprehensive list of examples for constructing an effective inspection checklist.

Wind Turbine Inspection Checklist Form Sample PDF Viewer

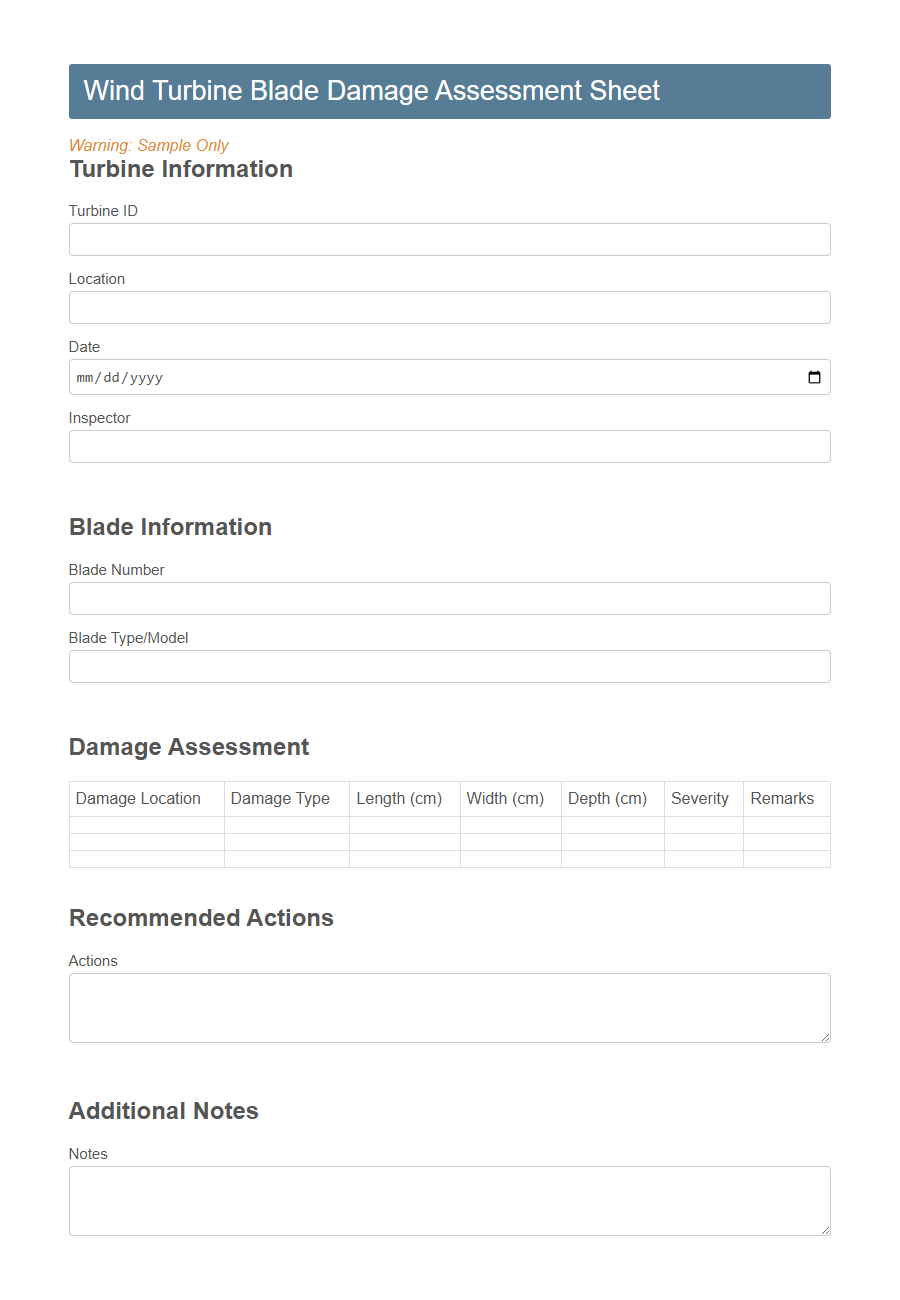

Image example of Wind Turbine Inspection Checklist Form:

Wind Turbine Inspection Checklist Form Samples

Wind Turbine Blade Damage Assessment Sheet - PDF - HTML

Wind Turbine Gearbox Oil Analysis Log - PDF - HTML

Wind Turbine Nacelle Condition Report Template - PDF - HTML

Wind Turbine Tower Structural Inspection Form - PDF - HTML

Wind Turbine Lightning Protection System Checklist - PDF - HTML

Wind Turbine Yaw System Maintenance Record - PDF - HTML

Wind Turbine Foundation Crack Monitoring Sheet - PDF - HTML

Wind Turbine Electrical Panel Safety Audit Form - PDF - HTML

Wind Turbine Rotor Hub Fastener Torque Log - PDF - HTML

Wind Turbine Fire Suppression System Inspection Template - PDF - HTML

Wind Turbine Control System Diagnostics Checklist - PDF - HTML

Wind Turbine Bird Strike Incident Report - PDF - HTML

Wind Turbine Access Ladder Safety Inspection Form - PDF - HTML

Wind Turbine Remote Monitoring Calibration Log - PDF - HTML

Wind Turbine Emergency Brake System Test Record - PDF - HTML

Introduction to Wind Turbine Inspection Checklist

A Wind Turbine Inspection Checklist is a crucial tool designed to ensure the safety, efficiency, and reliability of wind turbine operations. It systematically guides technicians through essential inspection points to identify potential issues early.

This checklist helps maintain optimal performance and extends the lifespan of wind turbines.

Importance of Routine Wind Turbine Inspections

Routine wind turbine inspections are essential to ensure operational efficiency and prevent costly breakdowns. Regular checks help identify potential issues before they escalate, maintaining safety and performance standards.

- Enhances Safety - Regular inspections detect structural and mechanical faults early, reducing the risk of accidents and injuries.

- Minimizes Downtime - Proactive maintenance based on inspection findings prevents unexpected failures, keeping turbines operational longer.

- Extends Equipment Lifespan - Consistent inspections help maintain turbine components in good condition, prolonging overall service life.

Implementing a detailed wind turbine inspection checklist form streamlines maintenance and supports effective asset management.

Pre-Inspection Safety Precautions

Before starting the wind turbine inspection, ensure all personnel are equipped with the necessary personal protective equipment, including helmets, gloves, and safety harnesses. Confirm that the weather conditions are suitable for safe climbing and equipment operation to prevent accidents. Verify that all safety protocols and emergency procedures have been reviewed and understood by the inspection team.

Exterior Structural Components Assessment

The Wind Turbine Inspection Checklist Form ensures a thorough assessment of exterior structural components. Key elements include blade condition, tower integrity, and foundation stability. Identifying cracks, corrosion, or damage early helps maintain turbine safety and efficiency.

Inspection of Blades and Rotor

The Wind Turbine Inspection Checklist Form is essential for ensuring the blades and rotor are functioning optimally.

Inspecting the blades involves checking for cracks, erosion, and any signs of structural damage that could impair performance. The rotor inspection focuses on blade pitch, balance, and the condition of the hub to maintain efficient energy production and prevent mechanical failure.

Tower and Foundation Integrity Checks

The Wind Turbine Inspection Checklist Form includes essential tower and foundation integrity checks to ensure safe and efficient operation.

Inspectors examine the tower for signs of corrosion, cracks, and structural deformities that could compromise stability. The foundation is assessed for cracks, settlement, or any damage that might affect the turbine's overall support and safety.

Electrical System Evaluation

Is the electrical system of the wind turbine free from visible damage or corrosion? Inspect all wiring, connectors, and components for signs of wear to ensure proper functionality and safety.

Are all electrical connections secure and properly tightened? Loose connections can cause power losses and pose safety hazards, so verify torque specifications and secure all terminals accordingly.

Is the insulation on cables intact and without cracks or degradation? Damaged insulation can lead to short circuits or electrical failures, requiring immediate repair or replacement.

Have all circuit breakers and protective devices been tested for correct operation? Properly functioning protection mechanisms prevent equipment damage and ensure operational reliability during faults.

Is the grounding system correctly installed and free from corrosion or damage? Effective grounding protects personnel and equipment from electrical faults and static discharge.

Are voltage and current readings within manufacturer's specified ranges during turbine operation? Abnormal readings could indicate underlying issues in the electrical system needing prompt attention.

Has the condition of the generator's electrical components been evaluated? Checking for overheating, unusual noises, or vibrations helps detect early signs of malfunction in the generator.

Is the control panel free from dust, moisture, and any contaminants that might affect electrical performance? Maintaining a clean environment prevents short circuits and improves the reliability of control electronics.

Are all warning and indicator lights functioning correctly? Properly operating indicators ensure clear communication of system status and potential faults to maintenance personnel.

Has the lightning protection system been inspected and tested? A functional lightning protection system safeguards the electrical components from voltage spikes caused by storms.

Nacelle and Gearbox Inspection Points

Regular inspection of the nacelle and gearbox is crucial for maintaining wind turbine performance and preventing costly failures. A detailed checklist ensures all critical components are thoroughly evaluated for early detection of wear or damage.

- Nacelle Housing Integrity - Check for any visible cracks, corrosion, or damage to the nacelle structure to ensure weather protection and mechanical stability.

- Gearbox Oil Level and Condition - Inspect the oil level and look for signs of contamination or degradation that could affect lubrication and gear performance.

- Gearbox Noise and Vibration - Monitor unusual sounds or excessive vibration that may indicate gear wear, misalignment, or bearing issues.

Recording and Reporting Inspection Findings

Accurate recording and thorough reporting of inspection findings ensure the reliability and safety of wind turbines. Clear documentation supports timely maintenance and effective communication among inspection teams.

- Detailed Data Entry - Each inspection point must be recorded precisely to track turbine performance and detect potential issues early.

- Standardized Reporting Format - Using a consistent format helps maintain clarity and facilitates easy review by maintenance personnel and engineers.

- Immediate Issue Notification - Critical faults identified during inspection should be reported promptly to enable swift corrective actions.