Industrial energy optimization proposal forms streamline the process of identifying cost-saving opportunities and improving energy efficiency in manufacturing settings. These forms typically include sections for current energy usage analysis, proposed methods for energy reduction, and estimated financial benefits. Clear examples of such forms help industries adopt best practices in sustainability and operational efficiency.

Industrial Energy Optimization Proposal Form Sample PDF Viewer

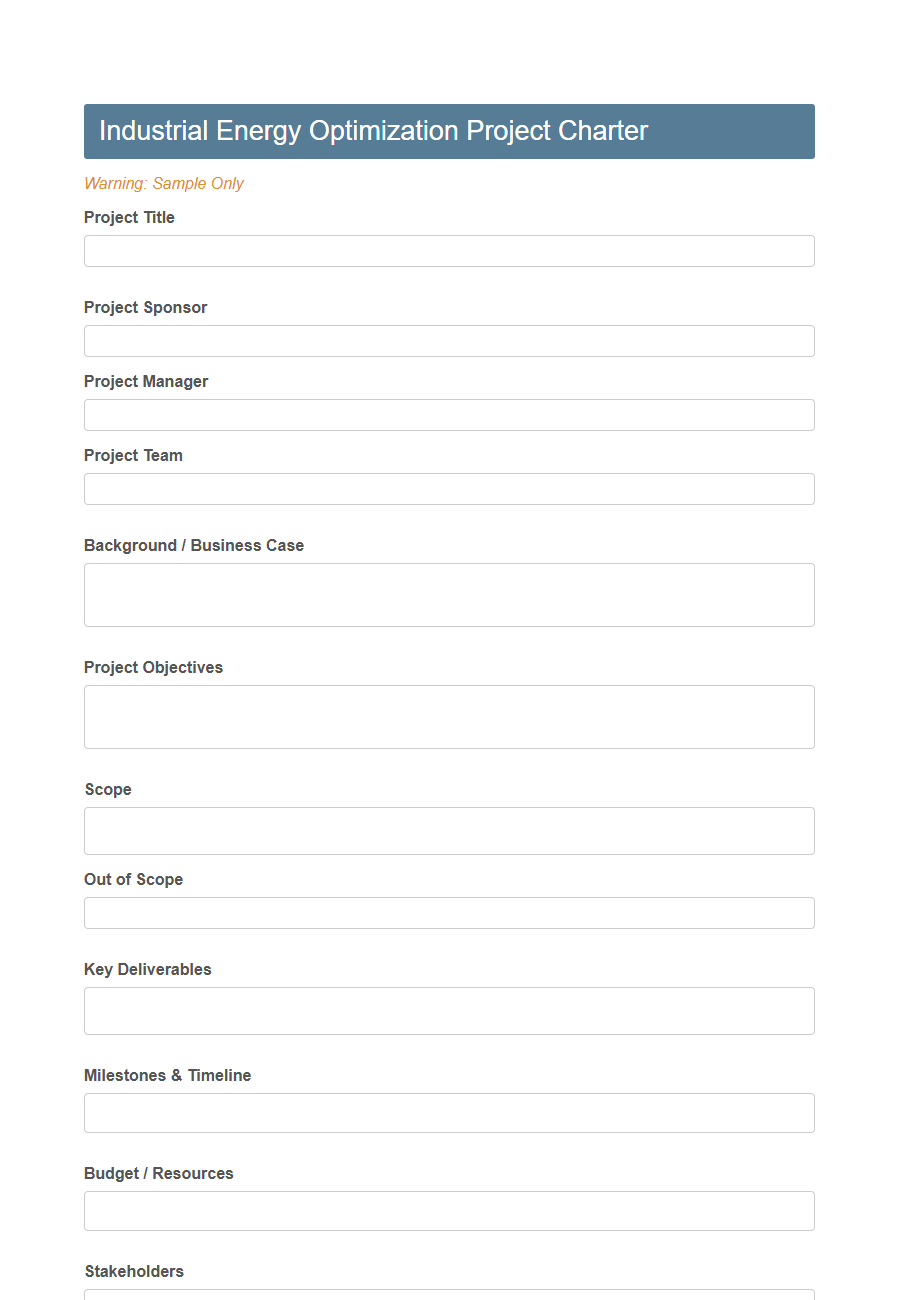

Image example of Industrial Energy Optimization Proposal Form:

Industrial Energy Optimization Proposal Form Samples

Industrial Energy Optimization Project Charter Template - PDF - HTML

Energy Efficiency Audit Report Template - PDF - HTML

Industrial Facility Energy Data Collection Sheet - PDF - HTML

Energy Optimization Cost-Benefit Analysis Form - PDF - HTML

Process Improvement Opportunity Identification Template - PDF - HTML

Industrial Energy Conservation Action Plan Format - PDF - HTML

Energy Optimization Technology Assessment Checklist - PDF - HTML

Proposal Review and Approval Routing Slip - PDF - HTML

ROI Calculation Template for Energy Optimization Projects - PDF - HTML

Stakeholder Engagement Summary Sheet - PDF - HTML

Pre-Implementation Risk Assessment Template - PDF - HTML

Industrial Equipment Energy Usage Log - PDF - HTML

Project Progress Monitoring Form - PDF - HTML

Supplier Quote Comparison Table (Energy Solutions) - PDF - HTML

Post-Implementation Energy Savings Verification Template - PDF - HTML

Introduction to Industrial Energy Optimization

What is industrial energy optimization? Industrial energy optimization involves improving energy efficiency in manufacturing processes to reduce costs and environmental impact. This approach uses advanced technologies and data analysis to identify energy-saving opportunities within industrial operations.

Objectives of the Proposal

The Industrial Energy Optimization Proposal Form aims to identify and implement strategies to reduce energy consumption in industrial processes. It serves as a structured approach to enhance energy efficiency, lower costs, and support sustainable operations.

- Energy Reduction - Focus on minimizing energy usage through advanced technologies and process improvements.

- Cost Savings - Facilitate financial benefits by decreasing energy expenses and optimizing resource allocation.

- Sustainability - Promote environmentally responsible practices that reduce carbon footprint and comply with regulations.

The form provides a clear framework for assessing, proposing, and tracking energy optimization initiatives within industrial settings.

Current Energy Consumption Analysis

Current Energy Consumption Analysis is essential to identify inefficiencies in industrial processes and establish a baseline for improvement. This analysis provides detailed insights into energy usage patterns, enabling targeted optimization strategies.

- Energy Audit - A comprehensive assessment of energy input and output across all equipment and processes reveals areas of excessive consumption.

- Data Collection - Systematic gathering of real-time energy data helps in pinpointing peak usage periods and energy waste sources.

- Performance Benchmarking - Comparing current energy metrics against industry standards highlights opportunities for reducing costs and enhancing efficiency.

Identification of Energy Inefficiencies

The Industrial Energy Optimization Proposal Form is designed to pinpoint areas where energy consumption is excessive or wasted. It gathers detailed data on machinery, processes, and energy use to identify inefficiencies that impact cost and performance. This targeted analysis enables the development of strategic solutions to enhance energy efficiency and reduce operational expenses.

Proposed Energy Optimization Strategies

Proposed energy optimization strategies aim to enhance efficiency and reduce operational costs in industrial processes. These strategies focus on innovative approaches to minimize energy consumption while maintaining productivity.

- Process Integration - Combining processes to recycle waste energy and improve overall system efficiency.

- Equipment Upgrades - Replacing outdated machinery with high-efficiency alternatives to lower energy use.

- Control System Optimization - Implementing advanced control technologies to fine-tune energy consumption in real-time.

Expected Benefits and ROI

Implementing an Industrial Energy Optimization Proposal can significantly reduce energy consumption and operational costs.

These improvements lead to enhanced productivity and a smaller environmental footprint. The expected return on investment is typically realized within a short period through decreased utility expenses and increased equipment efficiency.

Implementation Plan and Timeline

The Implementation Plan outlines the specific steps required to execute the energy optimization measures within the industrial facility. It details the allocation of resources, assigns responsibilities, and sets clear milestones for each phase of the project.

The Timeline provides a structured schedule to ensure timely completion, tracking progress from initial assessment through system integration and performance verification.

Adhering to the proposed plan and timeline guarantees efficient deployment and measurable energy savings.

Cost Breakdown and Funding Requirements

The Industrial Energy Optimization Proposal Form outlines detailed cost breakdowns and funding requirements to ensure project feasibility and financial transparency.

Precise identification of expenses such as equipment, labor, and operational costs is essential for effective budget management. Clear funding sources and requirements help stakeholders understand the financial commitments needed for successful project implementation.

Monitoring, Evaluation, and Reporting Methods

The Industrial Energy Optimization Proposal Form includes detailed sections for monitoring energy consumption through advanced metering and real-time data analytics. Evaluation methods focus on comparing energy performance against baseline metrics to identify efficiency gains and areas for improvement. Reporting protocols ensure transparent communication of results via periodic summaries and comprehensive dashboards to support decision-making.