Tracking industrial energy consumption through detailed usage log forms helps identify inefficiencies and optimize operational costs. These forms capture essential data such as power usage, peak demand times, and equipment-specific energy metrics. Using accurate logs supports sustainable practices and informs strategic energy management decisions.

Industrial Energy Usage Log Form Sample PDF Viewer

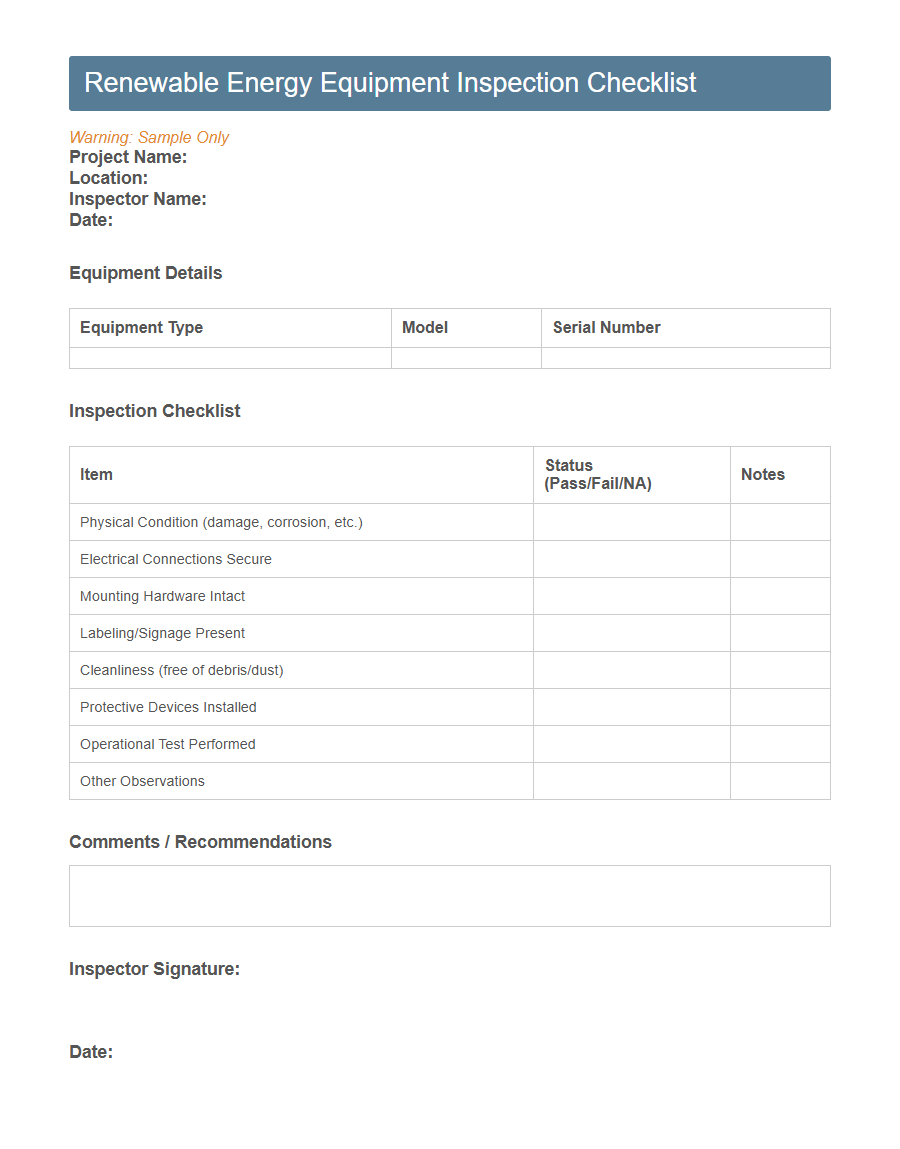

Image example of Industrial Energy Usage Log Form:

Industrial Energy Usage Log Form Samples

Renewable Energy Equipment Inspection Checklist - PDF - HTML

Factory Boiler Maintenance Record Sheet - PDF - HTML

Industrial Lighting Energy Audit Template - PDF - HTML

Compressed Air System Efficiency Log - PDF - HTML

Manufacturing Machine Idle Time Tracker - PDF - HTML

HVAC System Energy Consumption Report - PDF - HTML

Production Line Power Usage Monitoring Form - PDF - HTML

Energy Loss Incident Documentation Sheet - PDF - HTML

Facility Utility Submetering Record - PDF - HTML

Shift-Based Energy Consumption Log - PDF - HTML

Steam System Performance Assessment Template - PDF - HTML

Industrial Refrigeration Unit Energy Tracking Sheet - PDF - HTML

Power Factor Correction Equipment Log - PDF - HTML

Large Motor Start-Up Energy Use Tracker - PDF - HTML

Annual Industrial Facility Energy Benchmarking Report - PDF - HTML

Introduction to Industrial Energy Usage Logging

Industrial energy usage logging is essential for monitoring and managing the energy consumption of manufacturing processes and machinery. Accurate logging helps identify inefficiencies and opportunities for cost savings in energy use.

This form serves as a structured tool to record and analyze energy data systematically within industrial settings.

Importance of Documenting Industrial Energy Consumption

Documenting industrial energy consumption through an energy usage log form is crucial for identifying patterns and inefficiencies in energy use. Accurate records enable businesses to implement targeted energy-saving measures, reducing operational costs and environmental impact. Consistent monitoring supports compliance with regulatory standards and promotes sustainable industrial practices.

Key Components of an Energy Usage Log Form

What are the key components of an industrial energy usage log form? An energy usage log form typically includes sections for date, time, and specific equipment or machinery being monitored. It also records energy consumption levels, operational conditions, and any anomalies observed during the measurement period.

Types of Energy Sources Tracked in Industry

An Industrial Energy Usage Log Form tracks various types of energy sources utilized within industrial settings.

Common energy sources monitored include electricity, natural gas, steam, coal, and renewable energies like solar or wind power. This tracking helps industries optimize energy consumption and improve efficiency.

Step-by-Step Guide to Filling Out the Log Form

Filling out the Industrial Energy Usage Log Form accurately is essential for monitoring and managing energy consumption effectively. This step-by-step guide helps users document data clearly and systematically.

- Record Date and Time - Enter the specific date and time for each energy usage entry to maintain chronological order.

- Identify Energy Source - Specify the type of energy used, such as electricity, gas, or steam, to differentiate consumption categories.

- Log Consumption Amount - Input the exact amount of energy consumed in appropriate units to ensure precise tracking.

Best Practices for Accurate Energy Recording

Accurate energy recording in industrial settings requires consistent and systematic data entry using a standardized log form. Regular calibration of measurement instruments ensures the recorded data reflects true energy consumption. Training personnel on proper usage and emphasizing the importance of detailed entries improves overall reliability and facilitates better energy management decisions.

Common Mistakes to Avoid in Energy Logging

Accurate energy logging is crucial for effective industrial energy management.

Common mistakes include inconsistent data entry and failing to record all energy sources. These errors can lead to misleading analysis and missed opportunities for energy savings.

Integrating Digital Tools for Energy Log Management

Integrating digital tools into industrial energy usage log forms enhances accuracy and streamlines data collection. These technologies enable real-time monitoring and efficient energy management for industrial operations.

- Real-Time Data Capture - Digital tools allow instant recording of energy usage, reducing manual entry errors and saving time.

- Automated Reporting - Integration of software platforms generates comprehensive energy reports automatically, improving decision-making.

- Remote Access - Cloud-based systems provide remote monitoring capabilities, enabling continuous oversight and quicker response to energy anomalies.

Analyzing Data from Industrial Energy Logs

Analyzing data from industrial energy usage logs provides critical insights into consumption patterns and efficiency opportunities. Systematic examination of these logs supports informed decision-making for energy management and cost reduction.

- Identify Trends - Detect recurring patterns in energy consumption to highlight periods of high usage or inefficiency.

- Measure Performance - Compare energy data against production output to evaluate operational efficiency.

- Spot Anomalies - Recognize unexpected spikes or drops in energy usage indicating equipment issues or process deviations.

Thorough analysis of industrial energy logs drives strategic improvements and sustainable energy practices.