Chemical inventory update forms streamline tracking hazardous substances in laboratories and industrial settings. These forms typically include sections for substance name, quantity, storage location, and hazard classification to ensure compliance with safety regulations. Proper documentation supports efficient inventory management and enhances workplace safety protocols.

Chemical Inventory Update Form Sample PDF Viewer

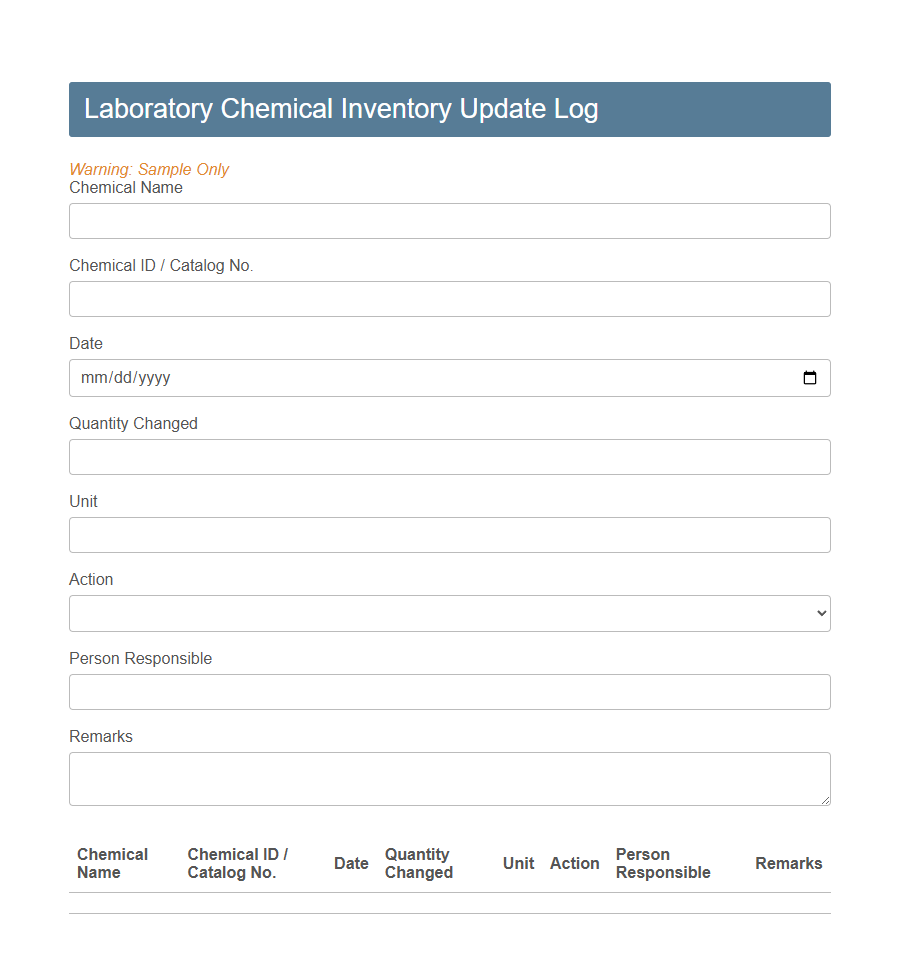

Image example of Chemical Inventory Update Form:

Chemical Inventory Update Form Samples

Laboratory Chemical Inventory Update Log - PDF - HTML

Hazardous Chemical Stock Adjustment Sheet - PDF - HTML

Chemical Storage Location Change Form - PDF - HTML

Research Lab Chemical Usage Report - PDF - HTML

Chemical Expiry and Disposal Notification Template - PDF - HTML

School Science Lab Chemical Restocking Request - PDF - HTML

Industrial Chemical Inventory Reconciliation Sheet - PDF - HTML

Environmental Compliance Chemical Update Form - PDF - HTML

Chemical Purchase and Consumption Record - PDF - HTML

Clinical Chemical Inventory Correction Form - PDF - HTML

Biotechnology Facility Chemical Revision Template - PDF - HTML

Small Business Chemical Stock Update Sheet - PDF - HTML

Chemical Transfer Between Labs Log - PDF - HTML

Emergency Chemical Spill Inventory Update - PDF - HTML

Teaching Laboratory Sample Chemical Update Form - PDF - HTML

Introduction to the Chemical Inventory Update Form

The Chemical Inventory Update Form is designed to facilitate accurate tracking of chemical substances within an organization. It ensures compliance with safety regulations by maintaining up-to-date records of chemical inventories.

- Purpose - The form collects detailed information about chemical quantities and locations to support safe handling and storage.

- Compliance - It helps organizations meet regulatory requirements by documenting chemical usage and inventory changes.

- Efficiency - The update process streamlines inventory management, reducing risks associated with outdated or incomplete chemical records.

Purpose and Importance of Accurate Chemical Inventory

The Chemical Inventory Update Form ensures accurate tracking of all chemicals stored and used within a facility. Maintaining an up-to-date inventory helps prevent hazardous incidents and supports regulatory compliance. Accurate records enable efficient risk management and resource allocation for safe handling and storage of chemicals.

Who Should Complete the Chemical Inventory Update Form?

Individuals responsible for managing or overseeing chemical substances within a facility should complete the Chemical Inventory Update Form. This includes laboratory managers, safety officers, and inventory coordinators who maintain accurate records of chemical usage and storage.

Anyone involved in handling or tracking chemicals must ensure the inventory is current by filling out this form regularly.

Key Sections of the Chemical Inventory Update Form

The Chemical Inventory Update Form is essential for maintaining accurate records of chemicals within a facility. It ensures compliance with safety regulations and helps manage chemical storage effectively.

- Chemical Identification - Captures the name, CAS number, and physical state of the chemical to uniquely identify each substance.

- Quantity and Location - Records the amount of chemical on-site and its specific storage location to facilitate proper handling and inventory control.

- Hazard Information - Details hazard classifications and safety precautions to ensure safe use and emergency response preparedness.

Step-by-Step Guide to Filling Out the Form

The Chemical Inventory Update Form helps track and manage hazardous materials in your facility.

Begin by entering the date and your contact information to ensure accurate record-keeping. Next, carefully list each chemical, including its name, quantity, and storage location for precise inventory control.

Common Mistakes to Avoid on the Inventory Update Form

Keeping an accurate Chemical Inventory Update Form is essential for laboratory safety and regulatory compliance.

Common mistakes include failing to list all chemicals present, which can lead to hazardous oversights. Incomplete or incorrect information about chemical quantities and locations often causes confusion and delays in emergency responses.

Submission Process and Deadlines

The Chemical Inventory Update Form must be submitted through the designated online portal to ensure accurate tracking of all hazardous materials on site. Submission deadlines are strictly enforced, typically requiring completion by the last day of each quarter to comply with regulatory standards. Timely updates help maintain safety protocols and prevent potential violations.

Best Practices for Chemical Inventory Management

How can organizations ensure accurate and efficient chemical inventory updates? Regularly utilizing a Chemical Inventory Update Form helps maintain precise records and prevents discrepancies in stock levels. Implementing standardized procedures for completing the form enhances data consistency and supports regulatory compliance.

What are the best practices for managing chemical inventories effectively? Keep the Chemical Inventory Update Form up to date by scheduling periodic reviews and immediate updates after chemical usage or receipt. Train staff on proper form completion and storage to minimize errors and ensure safety.

Why is it important to track chemical quantities and expiration dates using an update form? Monitoring quantities prevents overstocking or shortages, reducing waste and cost. Tracking expiration dates ensures safe usage and timely disposal, minimizing risks associated with expired chemicals.

How can digital tools improve the efficiency of chemical inventory updates? Digital inventory systems integrated with Chemical Inventory Update Forms streamline data entry and provide real-time tracking. Automating alerts for low stocks and expirations enhances inventory control and compliance.

What role does documentation play in best practices for chemical inventory management? Maintaining thorough documentation via Chemical Inventory Update Forms creates an audit trail for safety inspections and regulatory reporting. Clear records support accountability and informed decision-making regarding chemical handling and storage.

Ensuring Compliance with Regulatory Standards

The Chemical Inventory Update Form is essential for maintaining accurate records of hazardous substances within a facility. It plays a critical role in ensuring compliance with various regulatory standards governing chemical storage and usage.

- Regulatory Alignment - The form helps organizations align their chemical inventory with local, national, and international regulations, reducing legal risks.

- Safety Assurance - By regularly updating chemical data, the form supports safe handling and emergency preparedness in compliance with safety standards.

- Audit Readiness - Maintaining up-to-date records through the form ensures readiness for inspections and audits by regulatory agencies.

Consistent use of the Chemical Inventory Update Form strengthens compliance efforts and promotes a safer workplace environment.