A ship maintenance log form is essential for tracking repairs, inspections, and routine upkeep on vessels of all sizes. Detailed entries in the log help ensure safety, regulatory compliance, and operational efficiency. Examples of these forms illustrate how to document maintenance activities clearly and systematically.

Ship Maintenance Log Form Sample PDF Viewer

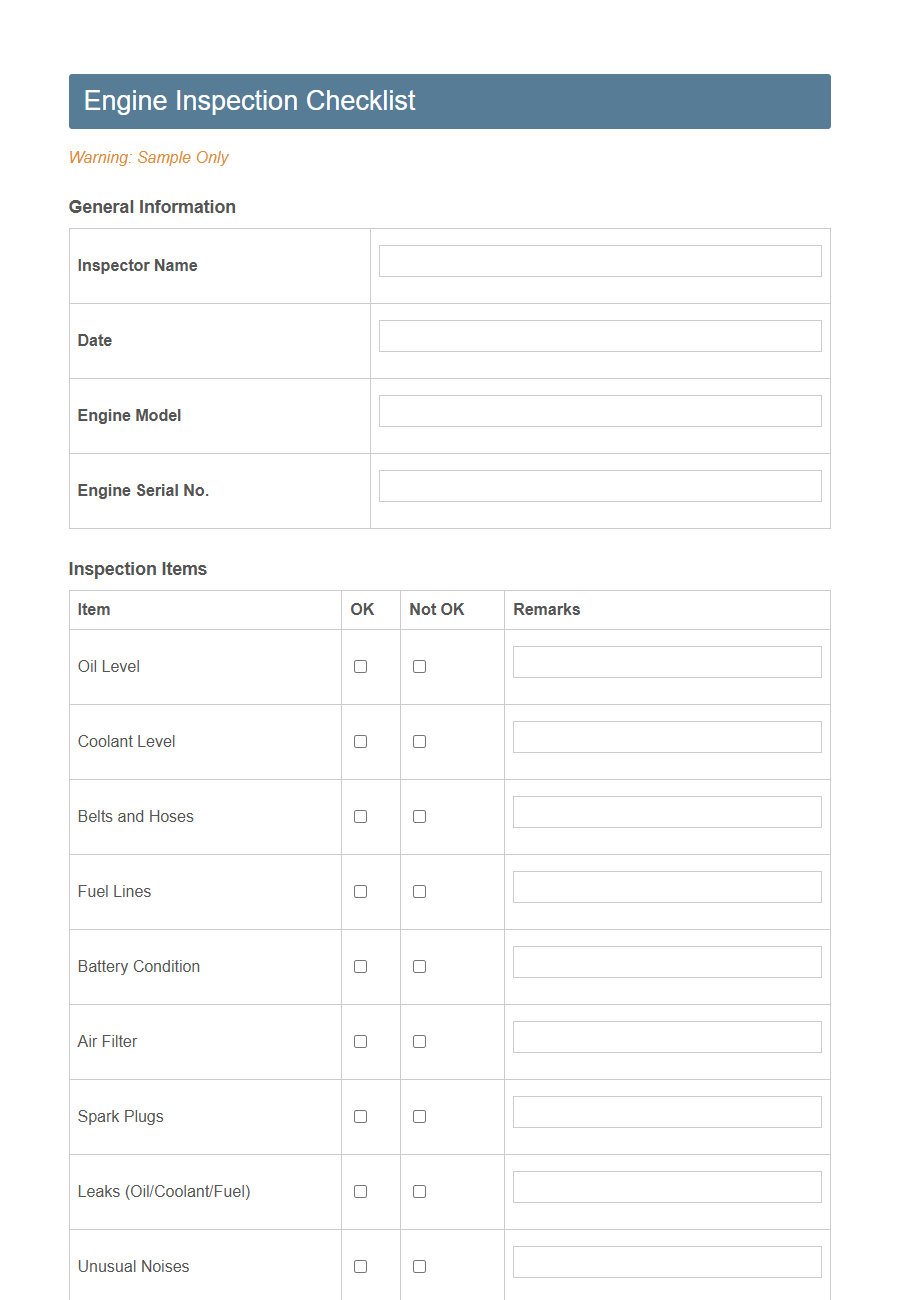

Image example of Ship Maintenance Log Form:

Ship Maintenance Log Form Samples

Engine Inspection Checklist Template - PDF - HTML

Hull Cleaning Record Sheet - PDF - HTML

Propeller Maintenance Report - PDF - HTML

Daily Vessel Condition Log - PDF - HTML

Electrical Systems Service Log - PDF - HTML

Lifesaving Equipment Inspection Form - PDF - HTML

Fuel System Maintenance Tracker - PDF - HTML

Scheduled Dry Docking Report Template - PDF - HTML

Ballast Water Treatment Record - PDF - HTML

Safety Equipment Audit Sheet - PDF - HTML

Deck Equipment Lubrication Log - PDF - HTML

Pollution Prevention Equipment Inspection Form - PDF - HTML

Corrosion Protection Maintenance Checklist - PDF - HTML

Introduction to Ship Maintenance Log Forms

A Ship Maintenance Log Form is a crucial document used to record all maintenance activities performed on a vessel. It ensures that all repairs, inspections, and routine upkeep are systematically tracked for safety and operational efficiency.

- Documentation of Maintenance Activities - It provides a detailed record of all maintenance tasks carried out on the ship, including dates and personnel involved.

- Enhances Safety and Compliance - The form helps maintain compliance with maritime regulations and safety standards by ensuring regular maintenance checks.

- Facilitates Preventive Maintenance - It assists in identifying potential issues early by monitoring equipment conditions and scheduling timely repairs.

Importance of Keeping a Ship Maintenance Log

Keeping a ship maintenance log is essential for ensuring the vessel's safety and operational efficiency.

This log provides a detailed record of all maintenance activities, helping to identify potential issues before they become serious problems. Regular documentation supports regulatory compliance and extends the lifespan of the ship by ensuring timely repairs and upkeep.

Key Components of a Ship Maintenance Log Form

A Ship Maintenance Log Form is essential for keeping detailed records of all maintenance activities on a vessel. It helps ensure safety, compliance, and efficient operation by tracking repairs and inspections systematically.

- Date and Time - Records when maintenance tasks are performed to maintain an accurate timeline of work completed.

- Maintenance Description - Details the specific tasks carried out to provide clear documentation of repairs or inspections.

- Technician or Crew Member - Identifies the individual responsible for the maintenance, ensuring accountability and traceability.

Types of Ship Maintenance Log Forms

Ship Maintenance Log Forms are essential for tracking the upkeep and repairs of various vessel components. These forms help ensure safety, compliance, and operational efficiency.

Common types include routine maintenance logs, repair logs, and inspection logs, each serving a specific purpose in managing a ship's condition.

How to Fill Out a Ship Maintenance Log Form

Filling out a Ship Maintenance Log Form requires precise and detailed information about the maintenance activities performed on the vessel.

Start by entering the date and time of the maintenance, along with the ship's name and identification number to ensure proper record keeping.

Record the specific system or equipment that was serviced, noting any parts replaced or repairs made.

Include the name and signature of the technician or engineer responsible for the work to maintain accountability and traceability.

Describe the nature of the maintenance task clearly and concisely.

Mention any observations or issues encountered during the process to provide a complete maintenance history for future reference.

Digital vs. Paper Maintenance Log Forms

Digital Ship Maintenance Log Forms offer real-time updates and easy access across multiple devices, enhancing efficiency and accuracy in record-keeping. Paper Maintenance Log Forms rely on manual entries, which can increase the risk of errors and make data retrieval time-consuming. Choosing digital formats supports streamlined operations and better compliance with maritime regulations.

Common Mistakes in Ship Maintenance Log Entries

Common mistakes in ship maintenance log entries include incomplete or vague descriptions of the work performed, which can lead to confusion during inspections and repairs. Failing to record the exact date and time of maintenance tasks often results in poor tracking of schedules and missed service intervals. Neglecting to document the names of personnel involved reduces accountability and complicates follow-up actions when issues arise.

Regulatory Compliance and Maintenance Logs

Why is regulatory compliance crucial in a ship maintenance log form? Regulatory compliance ensures that all maintenance activities meet international and local maritime safety standards. Accurate documentation helps prevent legal penalties and enhances the ship's operational safety.

How do maintenance logs contribute to effective ship management? Maintenance logs provide a detailed record of all repairs and upkeep performed on the vessel. This information supports timely inspections and helps identify recurring issues before they escalate.

Best Practices for Efficient Log Management

Efficient management of ship maintenance logs ensures accurate tracking of vessel upkeep and supports regulatory compliance. Implementing best practices enhances clarity, reduces errors, and streamlines maintenance workflows.

- Consistent Data Entry - Standardizing log formats and terminology prevents confusion and facilitates quick access to critical information.

- Regular Updates - Timely recording of maintenance activities captures real-time data for better decision-making and prevents oversight.

- Secure Storage - Maintaining logs in a centralized, protected system safeguards data integrity and enables easy retrieval during inspections.

Following these practices helps maintain vessel safety and operational efficiency through reliable maintenance documentation.