A dry docking specification form outlines the technical requirements and procedures for vessel maintenance during dry docking periods. This form ensures clarity, compliance with safety standards, and efficient project management. Reviewing various examples can help maritime professionals tailor specifications to their specific ship types and maintenance needs.

Dry Docking Specification Form Sample PDF Viewer

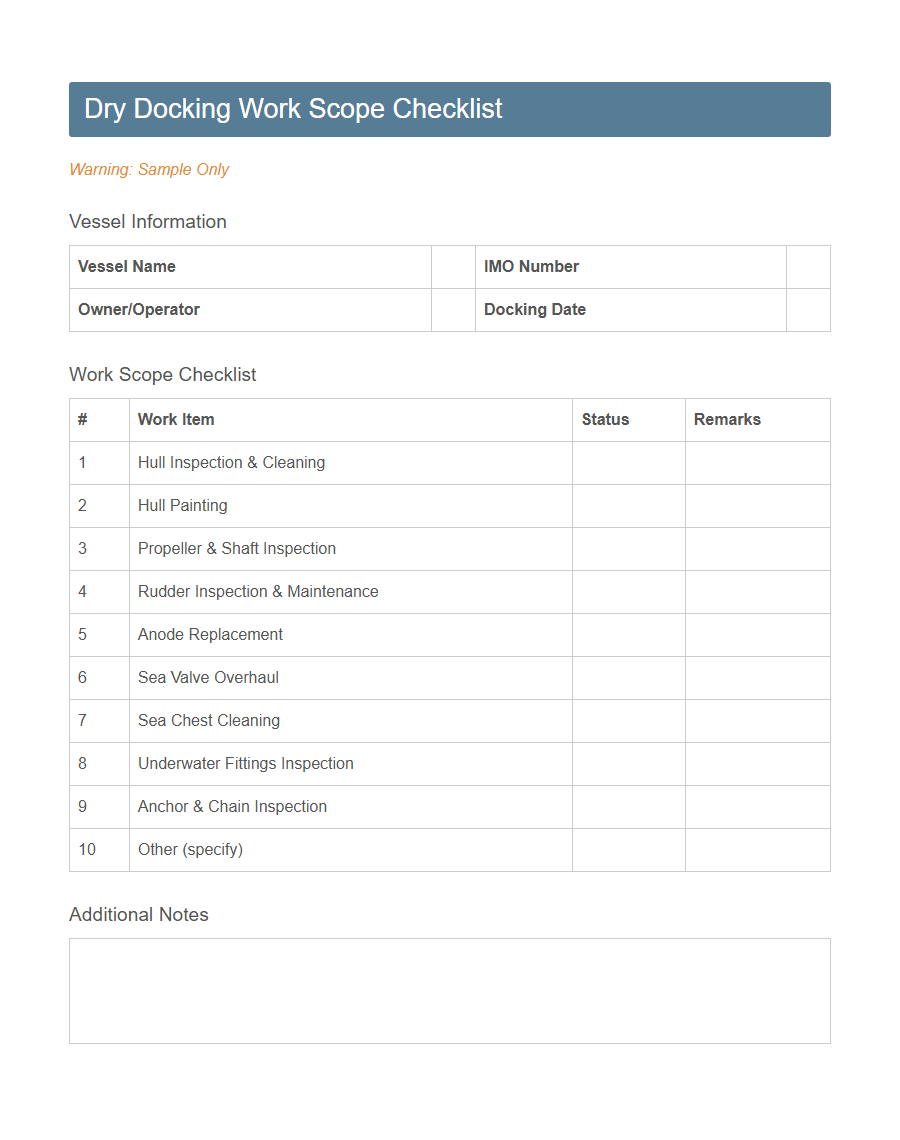

Image example of Dry Docking Specification Form:

Dry Docking Specification Form Samples

Dry Docking Work Scope Checklist - PDF - HTML

Vessel Pre-Docking Inspection Report Template - PDF - HTML

Dry Docking Repair Specification Sheet - PDF - HTML

Hull Cleaning and Painting Specification Form - PDF - HTML

Docking Sequence Schedule Template - PDF - HTML

Machinery Overhaul Specification Checklist - PDF - HTML

Underwater Equipment Inspection Form - PDF - HTML

Propeller Repair Specification Sheet - PDF - HTML

Dockside Safety Compliance Document - PDF - HTML

Steel Renewal Scope of Work Template - PDF - HTML

Sea Valve Maintenance Specification Form - PDF - HTML

Anode Renewal Documentation Template - PDF - HTML

Tank Entry Permit and Condition Report - PDF - HTML

Introduction to Dry Docking Specification Form

Dry Docking Specification Form is a critical document used to outline procedures and requirements during the dry docking of vessels. It ensures safety, compliance, and efficiency throughout the maintenance and repair process.

- Purpose - Defines the scope, standards, and expectations for dry docking activities to ensure clear communication among all parties involved.

- Content - Includes detailed technical requirements, timelines, and safety measures essential for successful dry dock operations.

- Importance - Serves as a reference to guarantee vessel integrity, regulatory compliance, and controlled execution of dry docking tasks.

Purpose and Importance of the Specification Form

The Dry Docking Specification Form outlines detailed requirements and standards for vessel maintenance during dry docking. It ensures alignment between shipowners, contractors, and regulators for efficient and safe repair operations.

- Standardization - It provides a uniform framework for documenting technical and operational expectations to avoid misunderstandings.

- Safety Assurance - The form helps identify critical safety measures to protect personnel and the vessel throughout the dry docking process.

- Quality Control - It serves as a reference to verify that repairs and inspections meet specified criteria and regulatory compliance.

Key Components of a Dry Docking Specification

The Dry Docking Specification Form outlines the essential requirements and procedures for the maintenance and inspection of a vessel during dry docking. It ensures that all critical aspects of the ship's structure and systems are addressed systematically to maintain safety and compliance.

Key components include detailed scope of work, timelines, technical standards, safety protocols, and quality assurance measures.

Required Documentation and Attachments

The Dry Docking Specification Form requires comprehensive documentation to ensure all maintenance and inspection tasks are clearly defined. Proper attachments support the verification and approval process, enhancing project accuracy and compliance.

- Technical Drawings - Detailed schematics outlining the vessel's structure and systems involved in the dry docking.

- Inspection Reports - Past evaluation documents that highlight areas needing attention during the dry dock period.

- Certification Copies - Valid certificates for safety, environmental compliance, and prior dry dock work to confirm regulatory adherence.

Including accurate and complete documentation is essential for a smooth and efficient dry docking operation.

Vessel Information and General Particulars

The Dry Docking Specification Form is essential for planning and executing maintenance on vessels.

It captures detailed Vessel Information, including name, type, and registration details to ensure accurate identification. General Particulars cover dimensions, tonnage, and engine specifications, providing a comprehensive overview for dry docking preparation.

Detailed Scope of Work

The Detailed Scope of Work in a Dry Docking Specification Form outlines all the specific tasks and inspections required during the dry docking process. It includes hull cleaning, painting, structural repairs, machinery overhauls, and system testing to ensure vessel safety and compliance. This section serves as a critical reference for contractors to accurately plan and execute the dry docking project.

Technical Standards and Compliance

Dry Docking Specification Forms ensure that all vessel maintenance meets stringent technical standards and regulatory requirements.

These forms provide detailed guidelines on the inspection, repair, and refurbishment processes to maintain vessel integrity and safety. Compliance with international maritime regulations is verified through this documentation, minimizing risks and enhancing operational reliability.

Safety and Environmental Considerations

What safety measures are essential in a Dry Docking Specification Form? Clear guidelines must be established to protect workers from hazards associated with confined spaces and heavy machinery. Proper training and use of personal protective equipment are crucial to prevent accidents.

How are environmental considerations addressed in a Dry Docking Specification Form? Procedures should minimize spills, emissions, and waste discharge to protect surrounding ecosystems. Use of environmentally friendly materials and proper waste disposal methods must be strictly enforced.

Submission Process and Timeline

The Dry Docking Specification Form must be submitted prior to the scheduled dry docking date to ensure timely approval and planning. All required details should be accurately completed and submitted through the designated digital platform or email address. Submission deadlines typically range from 30 to 60 days before dry docking to allow adequate time for review and necessary adjustments.