A machine downtime report form tracks and records instances when equipment is not operational, helping identify causes and improve maintenance strategies. Clear documentation of downtime events enables teams to analyze patterns, minimize disruptions, and enhance productivity. Utilizing examples of these forms streamlines reporting and ensures accurate data collection for effective decision-making.

Machine Downtime Report Form Sample PDF Viewer

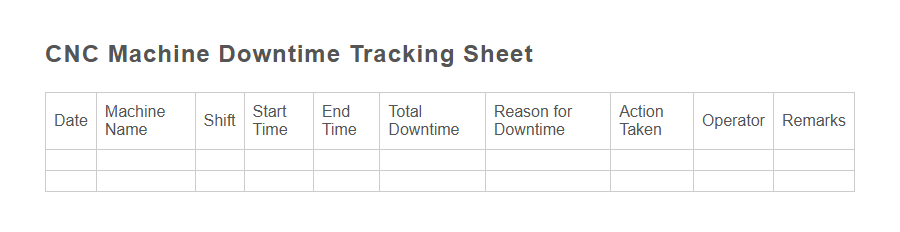

Image example of Machine Downtime Report Form:

Machine Downtime Report Form Samples

CNC Machine Downtime Tracking Sheet - PDF - HTML

Injection Molding Downtime Log Template - PDF - HTML

Pharmaceutical Production Downtime Report - PDF - HTML

Food Processing Equipment Downtime Form - PDF - HTML

Textile Machine Downtime Record Sheet - PDF - HTML

Packaging Line Downtime Analysis Template - PDF - HTML

Bottling Plant Downtime Incident Report - PDF - HTML

Automotive Assembly Downtime Log - PDF - HTML

Printing Press Downtime Documentation Form - PDF - HTML

Semiconductor Wafer Fab Downtime Report - PDF - HTML

Chemical Plant Reactor Downtime Sheet - PDF - HTML

HVAC System Downtime Log for Facilities - PDF - HTML

Hospital Medical Equipment Downtime Form - PDF - HTML

Introduction to Machine Downtime Report Forms

Machine Downtime Report Forms are essential tools used to document periods when equipment is not operational. These forms help identify the causes and durations of downtime, enabling better maintenance planning and operational efficiency. Accurate reporting through these forms supports data-driven decisions to minimize production losses and improve overall equipment effectiveness.

Importance of Tracking Machine Downtime

Tracking machine downtime is essential for optimizing production efficiency and minimizing operational costs.

Understanding when and why machines stop working helps identify recurring issues and areas for improvement. This information enables timely maintenance and reduces unexpected failures, ensuring smoother workflows and higher productivity.

Key Components of a Downtime Report Form

A Machine Downtime Report Form is essential for tracking and analyzing the periods when equipment is not operational. This form helps identify causes of downtime to improve maintenance and productivity.

- Downtime Duration - Records the exact start and end times of the machine stoppage to calculate total downtime.

- Cause of Downtime - Captures the reason behind the machine failure or stoppage for accurate troubleshooting and prevention.

- Operator Information - Includes details of the operator reporting the downtime to facilitate communication and accountability.

Effective downtime reporting supports timely interventions and enhances overall equipment efficiency.

Common Causes of Machine Downtime

Machine downtime significantly impacts productivity and operational efficiency across industries. Understanding the common causes helps in minimizing delays and improving maintenance strategies.

- Mechanical Failures - Equipment breakdowns due to worn parts or lack of lubrication often lead to unexpected stoppages.

- Operator Errors - Improper use or incorrect settings by personnel can cause machines to halt or perform inefficiently.

- Scheduled Maintenance - Planned inspections and repairs, while necessary, contribute to machine downtime during operational hours.

Step-by-Step Guide to Completing a Downtime Report

Completing a Machine Downtime Report Form accurately ensures precise tracking of equipment issues and helps improve overall productivity. Follow each step carefully to document the cause and duration of the downtime effectively.

- Identify the machine - Record the specific machine name or number where the downtime occurred.

- Note the downtime start and end times - Enter the exact times when the machine stopped and resumed operation to calculate total downtime accurately.

- Describe the cause of downtime - Provide a clear explanation of the issue or reason that caused the machine to stop working.

Best Practices for Accurate Downtime Reporting

How can accurate machine downtime reporting improve operational efficiency? Precise data helps identify recurring issues and prioritize maintenance tasks. This leads to reduced downtime and increased productivity.

What key details should be included in a machine downtime report form? The form must capture the exact time of downtime, duration, and the reason for the stoppage. Including operator comments and machine ID ensures comprehensive documentation.

Why is consistent reporting important for downtime analysis? Consistency allows for reliable trend identification and benchmarking over time. It enables management to make informed decisions on process improvements and resource allocation.

How can training impact the quality of downtime reports? Well-trained staff understand the importance of detailed and accurate reporting. This minimizes errors and enhances data reliability for maintenance planning.

What role does technology play in optimizing downtime reporting? Automated systems reduce manual entry errors and speed up the reporting process. Integration with maintenance software enables real-time monitoring and faster response.

Benefits of Analyzing Downtime Data

Analyzing downtime data through a Machine Downtime Report Form helps identify patterns and root causes of equipment failures. This insight enables targeted maintenance, reducing unplanned stoppages and improving overall productivity. Businesses can optimize resource allocation and enhance operational efficiency by addressing specific downtime issues promptly.

Tools and Software for Downtime Reporting

Machine Downtime Report Forms are essential for accurately tracking equipment failures and maintenance needs. Utilizing specialized tools and software streamlines data collection, enabling real-time monitoring and detailed analysis of downtime causes.

Digital platforms with customizable templates and automated reporting features enhance the efficiency of downtime management.

Tips for Preventing Frequent Machine Downtime

Machine downtime can significantly impact productivity and increase operational costs.

Regular maintenance and timely inspections are essential to identify potential issues before they cause failures. Training operators to follow standard procedures also helps minimize unexpected breakdowns and extends machine life.