Equipment calibration request forms streamline the process of ensuring devices meet precise performance standards. These forms capture essential information such as equipment details, calibration requirements, and service history. Proper completion of calibration requests enhances accuracy, compliance, and equipment reliability.

Equipment Calibration Request Form Sample PDF Viewer

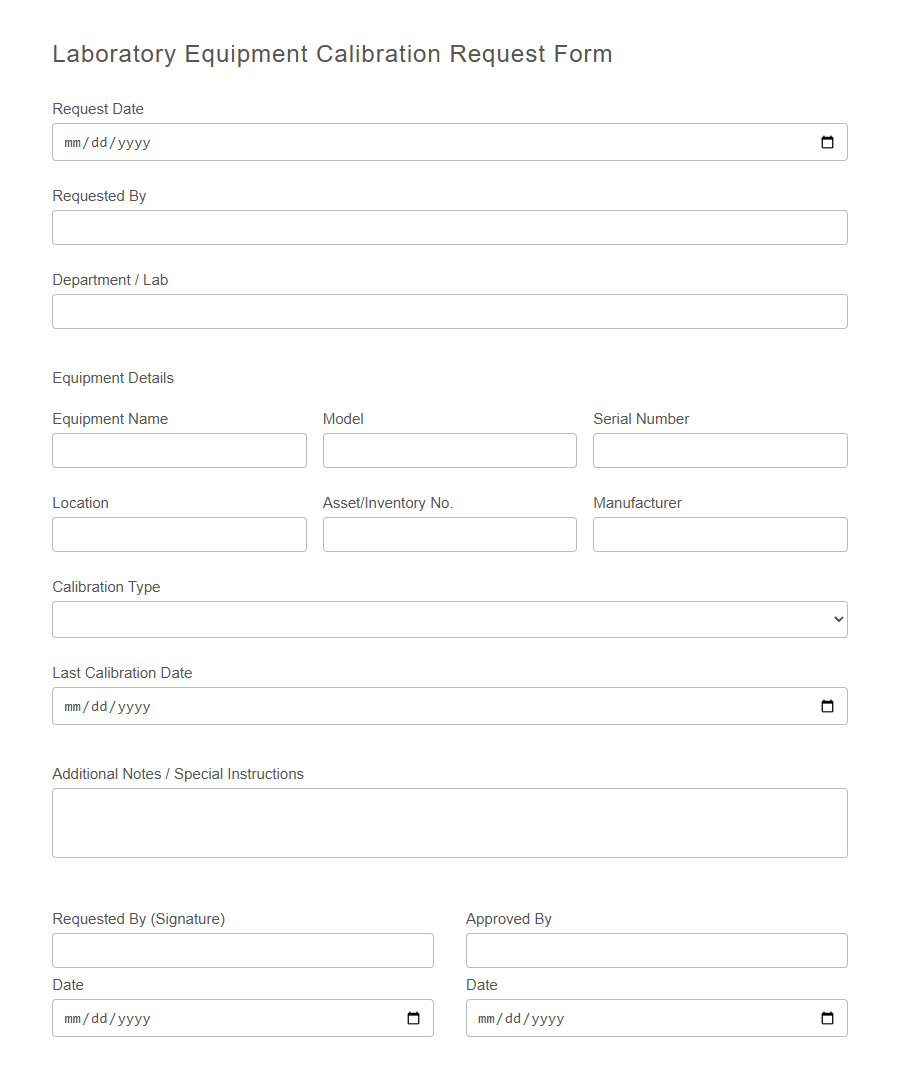

Image example of Equipment Calibration Request Form:

Equipment Calibration Request Form Samples

Laboratory Equipment Calibration Request Form - PDF - HTML

Medical Device Calibration Request Template - PDF - HTML

Industrial Machinery Calibration Service Request Form - PDF - HTML

Calibration Request Form for Pharmaceutical Equipment - PDF - HTML

Food Processing Equipment Calibration Request Template - PDF - HTML

HVAC Equipment Calibration Request Form - PDF - HTML

Electrical Test Equipment Calibration Request Form - PDF - HTML

Calibration Request Template for Biotech Instruments - PDF - HTML

Automotive Workshop Equipment Calibration Request Form - PDF - HTML

Aerospace Equipment Calibration Service Request Form - PDF - HTML

Calibration Request Form for Environmental Monitoring Devices - PDF - HTML

Chemical Plant Instrument Calibration Request Template - PDF - HTML

Construction Equipment Calibration Request Form - PDF - HTML

Oil & Gas Equipment Calibration Request Template - PDF - HTML

Calibration Request Form for Research Lab Instruments - PDF - HTML

Introduction to Equipment Calibration Request Forms

An Equipment Calibration Request Form is a critical document used to ensure that measuring instruments and equipment are accurate and functioning within specified standards. This form helps maintain quality control by documenting calibration needs and scheduling necessary services.

It streamlines the process of requesting calibration, tracking, and verifying equipment accuracy to support reliable operation and compliance with industry regulations.

Importance of Equipment Calibration in Quality Assurance

Equipment calibration ensures that measurement instruments provide accurate and reliable data critical for maintaining product quality. Consistent calibration prevents errors that could lead to costly defects or safety issues in production processes. Properly calibrated equipment supports compliance with industry standards and enhances overall customer satisfaction.

Key Components of a Calibration Request Form

An Equipment Calibration Request Form ensures accurate and consistent measurement by documenting all necessary calibration details. It streamlines the process of scheduling and verifying calibration activities for various instruments.

- Equipment Identification - Specifies the unique ID, model, and serial number to clearly identify the instrument requiring calibration.

- Calibration Requirements - Details the type of calibration needed, standards to be followed, and acceptable tolerance levels.

- Requester Information - Includes the name, department, and contact details of the individual requesting the calibration to ensure accountability and communication.

Step-by-Step Guide to Completing the Request Form

Begin by entering all relevant equipment details, including the asset number, model, and serial number, to ensure accurate identification. Next, specify the type of calibration required and the desired date for the service to align with maintenance schedules. Finally, review all information for accuracy before submitting the form to initiate the calibration process efficiently.

Essential Information Required for Calibration Requests

What details are essential for an equipment calibration request form? The form must include the equipment identification and the current condition to ensure proper calibration. Specifying the calibration date and the required standards helps maintain accuracy and compliance.

Common Mistakes When Filling Out Calibration Request Forms

Filling out an Equipment Calibration Request Form accurately is crucial to ensure proper equipment maintenance and precise calibration results. Common mistakes often lead to delays or errors in the calibration process.

- Incomplete Information - Missing details such as equipment serial numbers or calibration due dates can cause confusion and processing delays.

- Incorrect Data Entry - Providing wrong specifications or measurement units may result in improper calibration and unreliable results.

- Omitting Required Signatures - Failure to include necessary approvals or signatures can prevent the form from being accepted or processed on time.

Digital vs. Paper Calibration Request Forms

Equipment Calibration Request Forms are essential for ensuring accurate and reliable measurement instruments.

Digital Calibration Request Forms offer faster processing and easier data management compared to traditional paper forms. They reduce errors by automating data entry and enhance traceability through electronic records.

Best Practices for Submitting Calibration Requests

Submitting an Equipment Calibration Request Form accurately ensures precise maintenance of instrument performance.

Always provide detailed information about the equipment, including model number, serial number, and last calibration date. Clear and complete forms reduce processing time and prevent calibration errors.

Documenting and Tracking Calibration Requests

An Equipment Calibration Request Form is essential for accurately documenting and tracking all calibration activities. It ensures that every request is properly recorded to maintain equipment reliability and compliance.

- Consistent Record-Keeping - The form provides a standardized method for capturing detailed calibration requests, including equipment details and calibration requirements.

- Accountability - Tracking calibration requests through the form helps assign responsibility and monitor the status of each calibration task.

- Audit Trail - Documenting requests systematically creates a clear history of calibration events that supports quality assurance and regulatory audits.

Using an Equipment Calibration Request Form enhances precision and efficiency in managing calibration processes.