Power plant maintenance report forms play a crucial role in documenting equipment inspections, repairs, and routine upkeep to ensure operational efficiency and safety. These forms provide detailed records that help track maintenance activities, identify potential issues, and support compliance with industry standards. Using well-structured examples of maintenance report forms can enhance accuracy and streamline reporting processes in power plant management.

Power Plant Maintenance Report Form Sample PDF Viewer

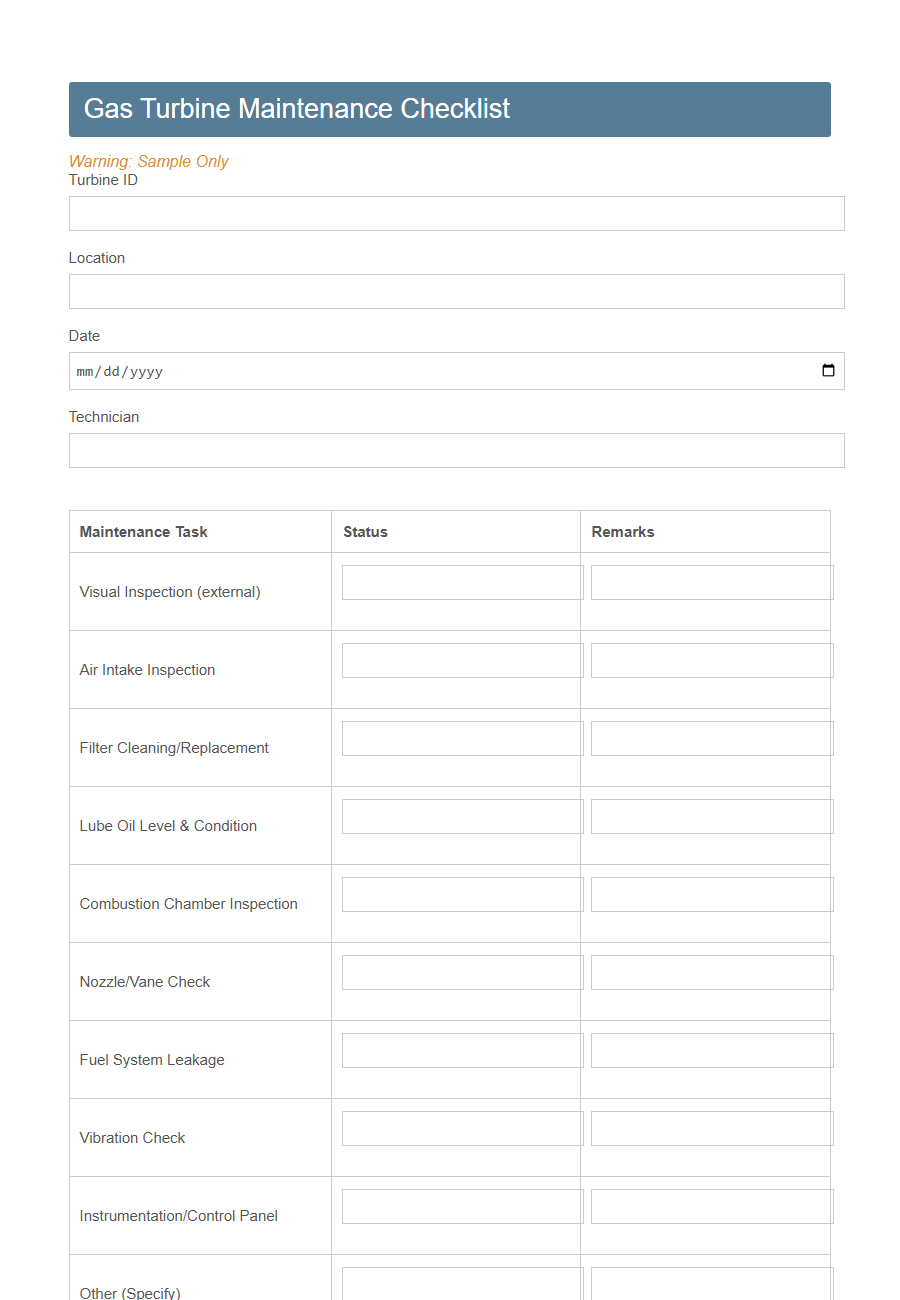

Image example of Power Plant Maintenance Report Form:

Power Plant Maintenance Report Form Samples

Gas Turbine Maintenance Checklist Template - PDF - HTML

Boiler Inspection Report Template - PDF - HTML

Cooling Tower Maintenance Log Form - PDF - HTML

Steam Turbine Vibration Analysis Report - PDF - HTML

Generator Preventive Maintenance Record - PDF - HTML

Condenser Tube Cleaning Documentation - PDF - HTML

Transformer Oil Testing Report Template - PDF - HTML

Heat Recovery Steam Generator (HRSG) Maintenance Sheet - PDF - HTML

Switchyard Equipment Servicing Report - PDF - HTML

Lubrication Schedule Tracking Form - PDF - HTML

Auxiliary Equipment Maintenance Checklist - PDF - HTML

Ash Handling System Inspection Report - PDF - HTML

Pump Overhaul Report Template - PDF - HTML

Introduction to Power Plant Maintenance Reporting

Power plant maintenance reporting is essential for ensuring the efficient and safe operation of power generation facilities.

This process involves documenting all maintenance activities, inspections, and repairs performed on equipment. Accurate maintenance reports help identify potential issues early, plan future maintenance, and comply with regulatory standards.

Purpose of the Maintenance Report Form

The purpose of the Power Plant Maintenance Report Form is to systematically document maintenance activities and equipment status. This form helps ensure all maintenance tasks are recorded accurately for future reference and compliance.

Maintenance reports enable plant operators to track performance, identify recurring issues, and schedule timely repairs. Clear documentation supports safety protocols and improves operational efficiency by providing a detailed history of maintenance work.

Key Components of the Report Form

The Power Plant Maintenance Report Form is essential for documenting maintenance activities and ensuring operational reliability. It captures detailed information to track the condition and performance of equipment.

- Equipment Identification - Records specific details about the machinery being maintained, such as serial number and location.

- Maintenance Performed - Describes the type of maintenance tasks carried out, including inspections, repairs, or replacements.

- Observations and Recommendations - Notes any issues found during maintenance and suggests necessary follow-up actions to prevent future failures.

This structured documentation supports effective communication and enhances maintenance planning in power plants.

Equipment Identification and Details

Accurate equipment identification is crucial for efficient power plant maintenance and tracking. Detailed information ensures proper documentation and timely servicing of each component.

- Equipment ID - A unique identifier assigned to each piece of equipment to avoid confusion and enable precise tracking.

- Manufacturer Details - Information about the equipment's manufacturer helps in sourcing parts and understanding technical specifications.

- Model and Serial Number - These details assist in identifying the exact equipment variant and maintaining accurate service records.

Scheduled vs. Unscheduled Maintenance

What is the difference between scheduled and unscheduled maintenance in a power plant maintenance report form? Scheduled maintenance is planned and performed at regular intervals to ensure equipment reliability. Unscheduled maintenance occurs unexpectedly due to equipment failure or urgent repairs needed to prevent downtime.

Description of Maintenance Tasks Performed

The Description of Maintenance Tasks Performed section details the specific activities carried out during the maintenance period. It includes inspections, repairs, replacements, and testing of critical power plant components to ensure optimal functionality. This section provides a clear and concise record of all actions taken to maintain system reliability and safety.

Parts Used and Inventory Tracking

The Power Plant Maintenance Report Form is designed to accurately document parts used during maintenance activities and ensure effective inventory tracking. It facilitates streamlined management of spare parts, reducing downtime and preventing shortages.

- Parts Used Recording - The form captures detailed information about each part utilized, including part numbers, quantities, and installation dates.

- Inventory Updates - It automatically updates inventory levels to reflect parts consumption, enabling real-time stock monitoring.

- Usage Analysis - The form supports analysis of part usage trends, helping optimize inventory procurement and minimize excess stock.

Safety Observations and Compliance

The Power Plant Maintenance Report Form includes a dedicated section for Safety Observations and Compliance to ensure all safety protocols are strictly followed during maintenance activities. This section records any safety hazards identified, corrective actions taken, and verification of adherence to regulatory standards. Maintaining thorough safety documentation helps prevent accidents and supports continuous improvement in workplace safety practices.

Signature and Authorization Section

The Signature and Authorization Section of the Power Plant Maintenance Report Form ensures that all completed tasks are verified by the responsible personnel. It provides a formal acknowledgment of the maintenance work, confirming accuracy and compliance with safety standards.

This section is critical for accountability and approval before the plant resumes normal operations.