A material requisition form in construction streamlines the process of requesting and tracking materials needed on-site. Accurate and detailed forms ensure timely procurement and efficient resource management. Reviewing examples helps construction professionals create effective requisitions that minimize delays and cost overruns.

Material Requisition Form (Construction) Sample PDF Viewer

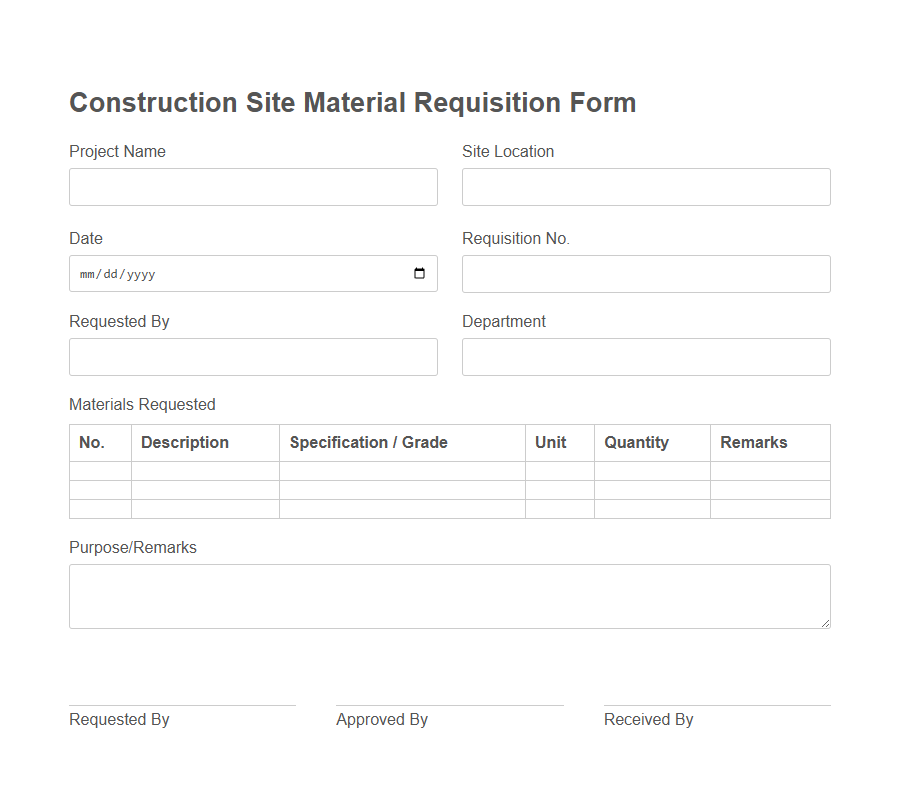

Image example of Material Requisition Form (Construction):

Material Requisition Form (Construction) Samples

Construction Site Material Requisition Form - PDF - HTML

Project-Specific Material Request Template (Building Works) - PDF - HTML

Civil Engineering Material Requisition Sheet - PDF - HTML

Concrete Supply Requisition Document - PDF - HTML

Mechanical Installations Material Requisition Form - PDF - HTML

Electrical Material Request Template (Construction Projects) - PDF - HTML

Structural Steel Material Requisition Checklist - PDF - HTML

Plumbing Materials Request Form (Residential Construction) - PDF - HTML

Finishing Materials Requisition Form (Interior Works) - PDF - HTML

Roofing Materials Requisition Sheet - PDF - HTML

HVAC Equipment Requisition Form - PDF - HTML

Road Construction Material Request Template - PDF - HTML

Renovation Project Material Requisition Form - PDF - HTML

Subcontractor Material Request Form - PDF - HTML

Emergency Material Requisition Template (Construction Site) - PDF - HTML

Introduction to Material Requisition Forms in Construction

A Material Requisition Form in construction is a critical document used to request and track the materials necessary for a project. It helps ensure that the right materials are ordered in the correct quantities and delivered on time to maintain workflow efficiency. This form serves as a communication tool between the site management and the procurement team, preventing delays and cost overruns.

Purpose and Importance of Material Requisition Forms

Material Requisition Forms in construction streamline the procurement process by specifying the exact materials needed for a project. These forms ensure accurate tracking and accountability of resources, preventing delays and cost overruns.

- Ensures Accurate Material Ordering - Clearly defines the type and quantity of materials required for each phase of construction.

- Facilitates Inventory Management - Helps monitor stock levels and prevents shortages or excesses on-site.

- Improves Budget Control - Tracks material usage to avoid unnecessary expenditures and maintain financial oversight.

Key Components of a Material Requisition Form

A Material Requisition Form in construction includes key components such as the description and quantity of materials needed to complete a specific task. It also contains project details like the job number, location, and request date to ensure accurate tracking and delivery. Approval signatures from supervisors or project managers are essential for authorization and accountability.

Step-by-Step Process for Filling Out the Form

The Material Requisition Form in construction is essential for requesting necessary materials efficiently.

Start by entering the project name and location to specify where the materials will be used. Include the date to keep track of the request timeline.

List the materials required by specifying their descriptions, quantities, and unit measurements clearly. This ensures accurate fulfillment and reduces mistakes.

Provide the purpose or reason for the material request to justify the need and prioritize procurement. Attach any supporting documents if necessary.

Fill in the requester's name and contact information to maintain communication throughout the process. This helps in case of clarifications or updates.

Obtain approval signatures from the project manager or supervisor to authorize the purchase or issuance of materials. This step enforces accountability.

Submit the completed form to the procurement or warehouse department to initiate the material supply process. Keep a copy for record-keeping and future reference.

Common Mistakes to Avoid in Material Requisition

Material Requisition Forms in construction play a crucial role in ensuring accurate and timely procurement of supplies. Avoiding common mistakes helps maintain project schedules and control costs effectively.

- Inaccurate Quantity Estimation - Underestimating or overestimating material quantities can lead to wastage or project delays due to shortages.

- Incomplete Documentation - Missing essential details such as specifications or approval signatures can cause confusion and approval delays.

- Poor Communication - Failing to coordinate with the procurement and project teams results in incorrect or unnecessary materials being ordered.

Careful attention to detail and clear communication prevent errors in material requisition, ensuring smoother construction operations.

Automation and Digital Solutions for Requisition Forms

Material Requisition Forms in construction are essential for tracking and managing the supply of materials needed on-site. Automation and digital solutions streamline this process by enabling real-time inventory updates and reducing human errors.

Digital platforms allow instant approvals and seamless communication among project teams, accelerating procurement and minimizing delays.

Approval Workflow and Accountability

A Material Requisition Form in construction ensures proper documentation and approval of materials needed for a project.

The approval workflow involves multiple levels of review, typically starting with the site engineer and progressing to project managers and procurement officers. This process guarantees accountability by tracking who requested, approved, and authorized the purchase of specific materials, reducing errors and delays.

Role in Inventory and Supply Chain Management

The Material Requisition Form in construction plays a crucial role in managing inventory levels by accurately documenting the materials needed for each project phase. It streamlines supply chain operations by ensuring timely procurement and reducing delays caused by material shortages.

- Accurate tracking - The form helps maintain precise records of material usage, preventing overstocking and wastage.

- Demand forecasting - It provides essential data for forecasting future material needs, enhancing procurement planning.

- Supplier coordination - The form facilitates clear communication with suppliers, improving order fulfillment and delivery schedules.

Best Practices for Material Requisition in Construction Projects

How can construction projects ensure efficient use of a Material Requisition Form? Using a well-structured Material Requisition Form helps in accurate tracking and timely procurement of materials, reducing delays. Clear specifications and quantities on the form prevent errors and excess inventory.

What are the key elements to include in a Material Requisition Form for construction? Essential details include project name, material description, quantities, delivery date, and approval signatures. These elements guarantee transparency and accountability in material handling.

Why is timely submission of Material Requisition Forms important in construction projects? Prompt submission ensures materials arrive when needed, avoiding work stoppages. It also allows procurement teams to manage suppliers and schedules effectively.

How does using a standardized Material Requisition Form benefit construction management? Standardization streamlines communication between site engineers, procurement, and suppliers. It reduces misinterpretation and helps maintain consistent documentation across projects.

What role does approval workflow play in the Material Requisition process on a construction site? Having defined approval stages ensures materials requested are justified and budgeted. It also minimizes unauthorized purchases and controls project costs efficiently.