A Traceability Record Form is essential for documenting the movement and history of products throughout the supply chain. It ensures accountability and quality control by capturing detailed information at each stage. Examples of these forms highlight various formats and key elements used across industries for effective traceability management.

Traceability Record Form Sample PDF Viewer

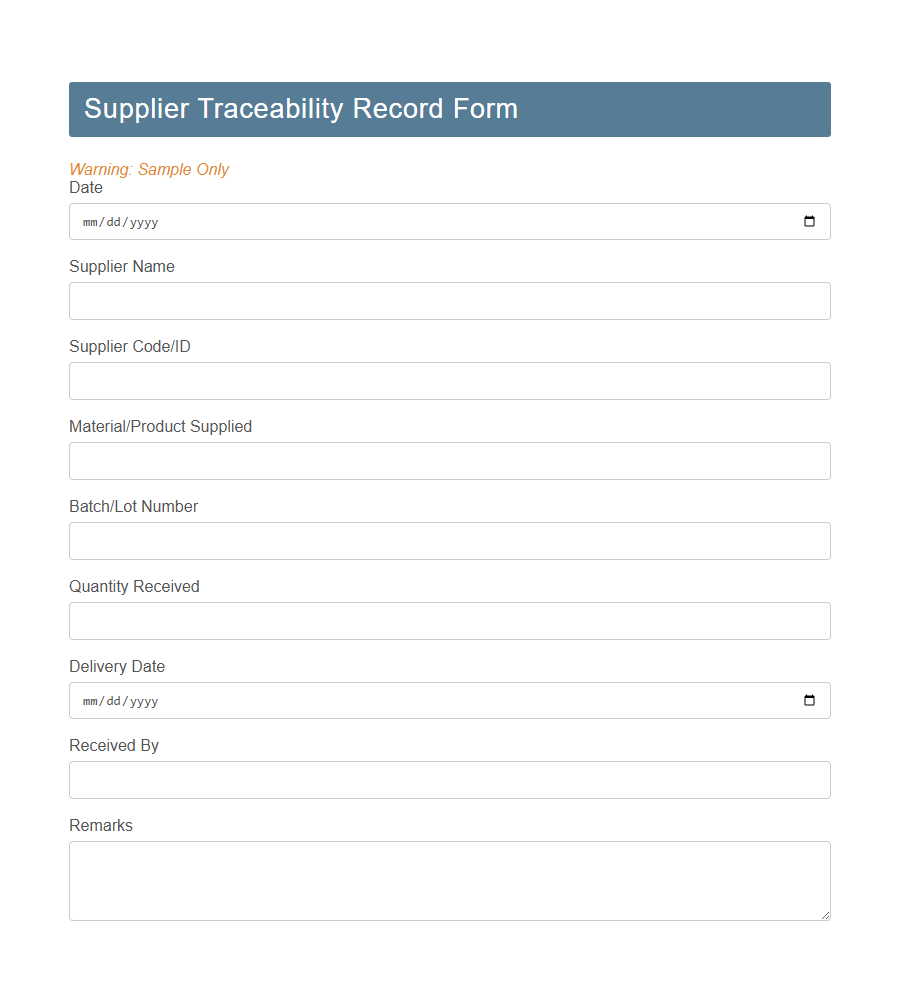

Image example of Traceability Record Form:

Traceability Record Form Samples

Supplier Traceability Record Form - PDF - HTML

Product Batch Traceability Record Form - PDF - HTML

Food Ingredient Traceability Record Template - PDF - HTML

Laboratory Sample Traceability Log Form - PDF - HTML

Medical Device Traceability Record Sheet - PDF - HTML

Construction Material Traceability Document - PDF - HTML

Animal Feed Traceability Record Template - PDF - HTML

Chemical Lot Traceability Record Form - PDF - HTML

Pharmaceutical Traceability Documentation - PDF - HTML

Seed Source Traceability Tracking Form - PDF - HTML

Fishery Product Traceability Record Template - PDF - HTML

Textile Roll Traceability Record Sheet - PDF - HTML

Hazardous Waste Traceability Form - PDF - HTML

Introduction to Traceability Record Forms

What is the purpose of a Traceability Record Form? A Traceability Record Form is used to track the history, application, or location of an item or product throughout its lifecycle. It ensures accountability and helps maintain quality control by providing detailed documentation.

Importance of Traceability in Quality Management

Traceability Record Forms play a crucial role in quality management by providing a systematic way to track the history and movement of products. This ensures accountability and enables prompt identification of issues during audits or recalls.

- Enhances Accountability - Traceability records document each step in the production process, assigning responsibility and improving transparency.

- Facilitates Problem Resolution - Accurate traceability helps quickly isolate defective batches, reducing downtime and minimizing product recalls.

- Supports Compliance - Maintaining detailed traceability records ensures adherence to industry standards and regulatory requirements.

Effective traceability strengthens overall product quality and customer trust.

Key Components of a Traceability Record Form

A Traceability Record Form is essential for tracking the history, application, or location of an item or batch throughout its lifecycle.

The key components include a unique identifier, detailed item description, date and time stamps, and involved personnel signatures. These elements ensure accurate tracking, accountability, and compliance with quality standards.

Types of Traceability Record Forms

Traceability Record Forms include batch traceability, which tracks products through production stages to ensure quality control. Another type is location traceability, documenting the movement and storage of items within facilities. Component traceability records the origin and usage of individual parts to support recalls and verify compliance.

How to Design an Effective Traceability Record Form

Designing an effective Traceability Record Form involves ensuring clarity, accuracy, and ease of use.

Identify key data fields such as product details, batch numbers, dates, and responsible personnel to capture essential traceability information. Use a logical layout with clear labels to minimize errors and facilitate quick data entry by users.

Incorporate standardized formats and drop-down menus to maintain consistency and reduce manual input mistakes. Prioritize space for signatures and timestamps to verify accountability and track changes over time.

Testing the form with actual users helps pinpoint usability issues and improves the design based on practical feedback. Ensure the form supports digital integration if possible, enabling efficient data retrieval and analysis.

Regularly update the form to reflect changes in processes, regulations, or product lines to maintain its effectiveness. Training staff on the importance and proper completion of the form enhances data reliability and overall traceability performance.

Best Practices for Traceability Documentation

Effective traceability record forms enhance product quality and compliance by providing clear, detailed documentation throughout the production process. Adhering to best practices ensures accurate tracking, accountability, and facilitates easy audits.

- Maintain Consistency - Use standardized formats and terminology to ensure all traceability records are clear and uniform.

- Ensure Accuracy - Record data promptly and verify entries to prevent errors that could compromise traceability.

- Secure Documentation - Store traceability forms in secure, accessible locations to protect data integrity and support retrieval during inspections.

Common Challenges in Maintaining Traceability Records

Maintaining traceability records often faces challenges such as incomplete or inconsistent data entries that compromise accuracy. Difficulty in tracking changes and updates over time can lead to gaps in the record history. Limited accessibility and poor organization of records hinder efficient retrieval and analysis.

Digital vs Paper-Based Traceability Record Forms

Traceability record forms are essential for tracking product history, and choosing between digital and paper-based formats impacts efficiency and accuracy. Digital forms streamline data management, while paper-based forms offer simplicity and accessibility in low-tech environments.

- Digital Traceability Record Forms - Enable real-time data entry, automatic updates, and easy access from multiple locations, enhancing accuracy and speed.

- Paper-Based Traceability Record Forms - Provide a tangible record that can be used without electronic devices, suitable for environments with limited technology access.

- Comparison of Benefits - Digital forms reduce human error and paper waste, whereas paper-based forms are less reliant on technical infrastructure and offer straightforward implementation.

Traceability Record Form Compliance Standards

Traceability Record Form compliance standards ensure accurate documentation of product history, enabling effective tracking from origin to final destination. These standards maintain data integrity, promote transparency, and support regulatory requirements across various industries.

Adhering to traceability standards reduces risks, improves quality control, and enhances accountability throughout the supply chain.